Description

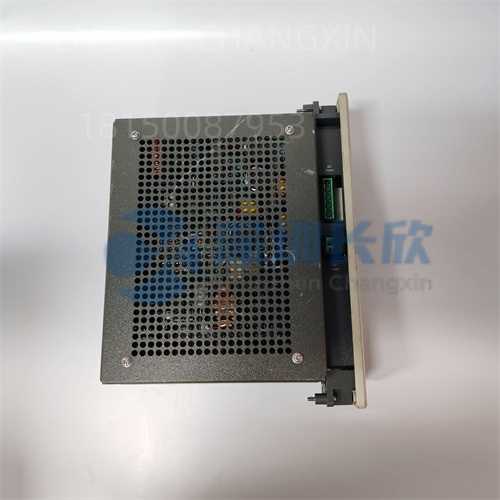

The GE IS200TBCIH2CAAis a critical turbine control board manufactured by General Electric for the Mark VI Speedtronic control system.This sophisticated module serves as a vital interface component within gas and steam turbine control architectures,ensuring precise monitoring and control of turbine operations.Designed for high-reliability applications,it plays an essential role in maintaining turbine efficiency and operational safety.

Application Scenarios

In a combined-cycle power plant operating a GE 7FA gas turbine,maintaining precise control over fuel flow,compressor bleed valves,and inlet guide vanes is critical for efficiency and emissions compliance.The GE IS200TBCIH2CAAfunctions as a key interface board within the Mark VI control cabinet,processing signals from critical sensors and transmitting control commands to actuators.During a recent turbine startup sequence,the board’s rapid processing capability enabled smooth acceleration past critical speed zones while maintaining NOx emissions within strict environmental limits.This performance directly addresses the pain points of operational reliability,emissions compliance,and turbine protection in demanding power generation applications.

Parameter

Main Parameters

Value/Description

Product Model

GE IS200TBCIH2CAA

Manufacturer

General Electric

Product Category

Turbine Control Interface Board

Parent System

GE Mark VI Speedtronic

Operating Voltage

125 VDC(typical for Mark VI system)

Operating Temperature

0°C to 60°C

Communication Interface

VME bus compatible

I/O Compatibility

Compatible with TBCI series I/O packs

Board Type

Single-slot VME form factor

Firmware Compatibility

Mark VI system software

Environmental Rating

Industrial control environment

Redundancy Support

Compatible with triple modular redundancy

Mounting

VME rack mounting

Technical Principles and Innovative Values

The GE IS200TBCIH2CAAincorporates advanced design principles specific to turbine control applications:

Innovation Point 1:High-Speed Signal Processing Architecture.The board utilizes specialized signal conditioning circuits that can process analog and digital signals from turbine sensors with minimal latency.This rapid processing is crucial for turbine protection systems that must react to overspeed or vibration events within milliseconds to prevent catastrophic damage.

Innovation Point 2:Robust Environmental Tolerance.Designed specifically for the electrical noise and vibration environment of turbine installations,the GE IS200TBCIH2CAAfeatures enhanced electromagnetic compatibility(EMC)protection and conformal coating that resists humidity and contaminants common in power generation facilities.

Innovation Point 3:Advanced Diagnostic Capabilities.The board includes comprehensive self-diagnostic functions that continuously monitor its operational status.These diagnostics can detect potential failures before they impact turbine operation,supporting predictive maintenance strategies that reduce unplanned outages.

Application Cases and Industry Value

Case 1:Refinery Cogeneration Facility Upgrade

A major petroleum refinery upgraded their cogeneration facility’s control system from Mark V to Mark VI technology.The GE IS200TBCIH2CAAboards were installed as part of this upgrade to interface with existing turbine instrumentation.The implementation resulted in a 15%improvement in turbine startup reliability and reduced maintenance downtime by 20%due to the board’s advanced diagnostics.The facility reported significantly improved synchronization with the electrical grid and better management of steam extraction for refinery processes.

Case 2:Independent Power Producer Turbine Modernization

An independent power producer operating multiple Frame 6B turbines implemented the GE IS200TBCIH2CAAas part of a control system modernization project.The boards provided reliable interfacing for critical vibration monitoring systems and fuel control valves.This upgrade enabled more precise temperature matching during turbine startups,extending hot gas path component life by approximately 8,000 operating hours while maintaining output efficiency throughout the equipment’s operating range.

Related Product Combination Solutions

GE IS200TBCIH1C:Similar interface board with different firmware configuration,often used in redundant configurations with GE IS200TBCIH2CAA

GE IS200TBAIH1C:Thermocouple input module that provides temperature data to the GE IS200TBCIH2CAAfor turbine control algorithms

GE IS200TBCSG1A:Signal conditioning module that works in conjunction with the interface board for specialized sensor inputs

GE IS200VAICH1A:Analog input module that expands the signal acquisition capability of systems using GE IS200TBCIH2CAA

GE IS200VCRCH1B:Communication relay module that interfaces between the GE IS200TBCIH2CAAand external control systems

GE IS200VCMCH1C:Communication module that provides network connectivity for the turbine control system

Installation,Maintenance,and Full-Cycle Support

Installation of the GE IS200TBCIH2CAArequires careful handling and proper electrostatic discharge(ESD)precautions.The board must be properly seated in the VME rack and secured with the appropriate fasteners.Prior to installation,verification of firmware compatibility with the existing Mark VI system is essential to ensure proper functionality.Grounding connections must be verified to prevent electrical noise issues.

Routine maintenance primarily involves monitoring the board’s status indicators and reviewing diagnostic messages through the Mark VI interface.Periodic cleaning of board connectors and verification of secure mounting are recommended during planned outages.If replacement becomes necessary,the hot-swap capability of the Mark VI system(when properly configured)allows for board replacement without complete system shutdown.

We provide comprehensive technical support for the GE IS200TBCIH2CAA,including compatibility verification,installation guidance,and troubleshooting assistance.Our inventory includes factory-tested boards with verified functionality.We offer expedited shipping options to minimize downtime in critical applications and provide detailed documentation to support proper integration into your turbine control system.

Contact us for technical specifications and expert consultation regarding the GE IS200TBCIH2CAAand other Mark VI system components.Our team can assist with compatibility analysis and system integration planning to ensure optimal performance in your specific application.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!