Description:

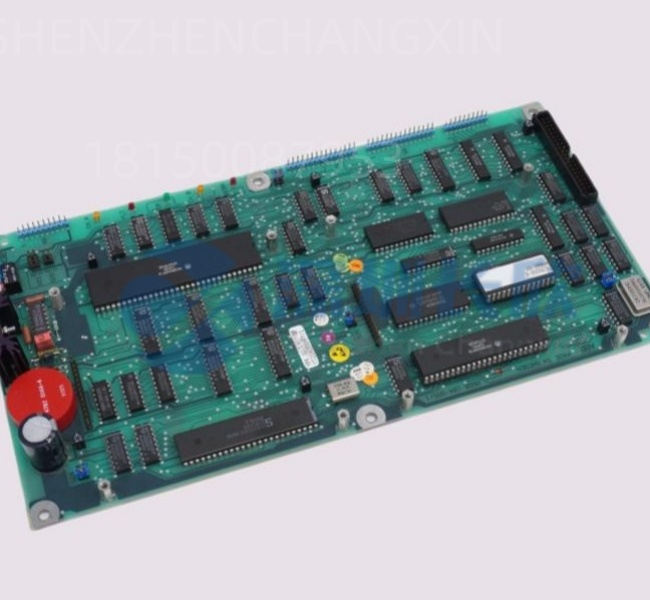

The GE IS200TRLYH1BGFis a critical relay output and trip interface board designed and manufactured by GE(General Electric)for its Mark VI and Mark VIe Speedtronic turbine control systems.This board serves as a vital safety and control interface,translating logic-level commands from the turbine controller into robust,isolated relay outputs to execute critical trip functions,start permissives,and equipment sequencing.

Application Scenarios:

In a combined-cycle power plant,the gas turbine must shut down within milliseconds if a critical failure—like a sudden loss of lube oil pressure or an extreme overspeed condition—is detected.The controller’s processor calculates the trip command,but this low-voltage electronic signal cannot directly interrupt the high-current circuits of the turbine’s fuel shutoff valves or generator breaker.This is where the IS200TRLYH1BGFboard is essential.Mounted in the turbine control cabinet,it receives the trip signal from the controller’s Triple Modular Redundant(TMR)processors.Its high-integrity relays then physically open or close,directly de-energizing the solenoid on the emergency fuel valve,causing an immediate and safe shutdown.This application demonstrates the board’s role as the final,fail-safe electro-mechanical link in the safety chain,protecting multi-million dollar assets from catastrophic damage.

Parameter:

Main Parameters

Value/Description

Product Model

IS200TRLYH1BGF

Manufacturer

General Electric(GE)

Product Category

Relay Output/Trip Interface Board

Compatible System

GE Mark VI,Mark VIe Turbine Control System

Primary Function

Provides isolated relay outputs for trip,alarm,and control signals

Relay Type

Electromechanical or high-grade solid-state relays

Contact Rating

Typically 5A 30V DC or 250V AC(dependent on specific relay population)

Isolation

High-voltage isolation between controller logic and field-side circuits

Input Signals

Connects to TMR processor outputs or other control boards via backplane

Status Indication

LED indicators for relay coil status(energized/de-energized)

Power Supply

Powered from the Mark VI(e)rack’s+5V,±15V DC supplies

Mounting

Installs into a designated slot in the Mark VI/Vie turbine control rack

Technical Principles and Innovative Values:

Innovation Point 1:Safety-Centric,Isolated Output Design.The core principle of the IS200TRLYH1BGFis guaranteed isolation and reliability.It acts as a robust barrier,using relays to completely separate the sensitive,low-voltage electronic control system from the often noisy and high-power field circuits.This isolation prevents faults,transients,or ground loops in the field wiring from feeding back into and damaging the critical TMR controllers.The relay’s physical contacts provide a definitive,failsafe state(open or closed)that is not susceptible to the software or data corruption risks that might affect a purely digital communication link.

Innovation Point 2:Direct Interface for Triple Modular Redundant(TMR)Systems.In the Mark VIe safety architecture,the IS200TRLYH1BGFis designed to interface seamlessly with the TMR processors.Critical trip commands from the three redundant processor channels can be wired to vote on a single,high-reliability”master trip relay”on this board.Only if two-out-of-three channels agree is the trip relay de-energized.This design hardwires the TMR voting logic into the safety circuit,providing an extra layer of hardware-based fault tolerance that is extremely resistant to spurious trips or failures.

Innovation Point 3:Modular and Serviceable Construction.The board is designed for maintainability within the demanding 24/7 power generation environment.Individual relay modules may be socketed,allowing for replacement without soldering or replacing the entire board.Clear LED status for each relay channel enables technicians to instantly visually confirm the commanded state versus the actual state,a crucial feature for rapid troubleshooting during startup or an outage.This modularity minimizes Mean Time to Repair(MTTR).

Application Cases and Industry Value:

Case Study:Petrochemical Plant Cogeneration Unit Trip System Upgrade.A refinery’s cogeneration unit,powered by a GE Frame 6B gas turbine,experienced unreliable trips due to aging relay hardware in its legacy control system,causing unplanned shutdowns that disrupted steam and power supply to the refinery processes.

During a control system upgrade to a GE Mark VIe,the new system included the IS200TRLYH1BGFboard to handle all critical trip functions(overspeed,flame failure,high vibration)and permissives(lube oil pressure ok,hydraulic pressure ok).The board’s high-quality relays and clear diagnostics provided a level of reliability the old system lacked.During commissioning,a simulated test of all trip functions confirmed crisp,positive relay action every time.In the two years since startup,the unit has had zero control-system-related false trips.The plant engineer estimated that avoiding just one unplanned outage saved over$500,000 in lost production,providing a clear and rapid return on investment for the control system upgrade,with the IS200TRLYH1BGFbeing a cornerstone of its new reliability.

Related Product Combination Solutions:

The IS200TRLYH1BGFfunctions within a comprehensive turbine protection scheme.Key related components include:

TMR Processor Modules(e.g.,IS200TBAIH2C):These generate the logic-level trip commands that the IS200TRLYH1BGFconverts into relay outputs.

Termination Board(e.g.,IS200TBCIH2C):This board provides the physical screw terminals for field wiring(from solenoid valves,breakers)to connect to the relay contacts on the IS200TRLYH1BGF.

Power Supply Modules(e.g.,IS200PSCAH1A):Provide clean,regulated DC power to the entire rack,including the relay board.

I/O Pack Modules(e.g.,IS200VAIOH1B):Handle analog and digital inputs(like vibration,temperature)that provide the data leading to a potential trip command processed by the TMR and executed by the IS200TRLYH1BGF.

Dynamic Signal Interface Board(e.g.,IS200DTAIH1B):Could provide input from keyphasor or vibration sensors,the signals from which might ultimately cause a trip executed by the IS200TRLYH1BGF.

Mark VIe Control Rack&Backplane:The VME rack that houses and interconnects all these modules.

Installation,Maintenance,and Full-Cycle Support:

Installation involves carefully inserting the board into its assigned slot in the Mark VI/Vie rack and securing it with the retaining screws.The critical work is in the external wiring:the control signals from the TMR processors must be correctly landed on the board’s input headers,and the output relay contact wiring to the termination board must be meticulously done according to the schematic.Proper torque on all connections is vital to prevent heat buildup and failure.

Routine maintenance involves periodic testing during planned outages.This includes a visual inspection of the board for overheating signs,verification of LED status against controller commands,and functional testing of the trip circuits by simulating trip conditions and verifying the relay contacts change state and actuate the final field device(e.g.,the fuel valve closes).The board’s design facilitates this testing.We provide comprehensive support for this critical component.Every IS200TRLYH1BGFboard we supply is sourced from certified channels and undergoes a rigorous validation process,including board inspection,power-on testing,and functional verification of relay operation.We back it with technical expertise for integration and troubleshooting,helping ensure the continued safety and reliability of your turbine control system.

UFC921A101 3BHB024855R0101 UFC911B106 3BHE037864R0106 UDC920BE01 3BHE034863R0001 XVC770BE101 3BHE021083R0101 KUC755AE105 3BHB005243R0105 LXN1604-6 3BHL000986P7000 LWN2660-6E 3BHL000986P7002 UFC789AE 38HE014022P102 3BHL000734P0003 SLOV4.6/5.3 HIES308461R0012 HIES208441R.. ID8A92485001/022 3BHB009410R000 SG000247 3BHL000986P1006 XVC724BE101 3BHE009017R0102 DKTFM418B 3BHB015651P0001 PU180/63E 3BHB00916230001 HIES308461R0012 FPX86-9345–B 3BHL000986P0006 3BHL000734P0003 SLOV4.6/5.3 UFC921A101 3BHE024855R0101 PPC907BE101 3BHE024577R0101 XVC724BE101 3BHE009017R0102 IEC60129,62271-102 MI-CONP KUC755AE105 3BHB005243R0105 HIES308461R0012 MG160MD2-42FF300-F1 PTC 160℃ TP211 MG160MD2-42FF300-F1 ABB S-073N ALU 3BHB009884R5211 ABB S-093H 3BHB030478R0309 ABB S-123H 3BHB030479R0512 ABB UFC912A101 3BHE039426R0101 ABB 5SHY4045L0001 3BHB018162R0001 ABB S-113N 3BHB018008R0001 W4 KUC755AE105 3BHB005243R0105 HIEE401807R0001 3BHB046719R0008 STRAUB FLEX1L TB820V2 S-053M 3BHB012897R003 *12 3BHB014556R0001 3BHB010823R0002 CDP312R XVC768AE102 UFC789AE101 S-073N KU C755AE105 XVC770BE101 UFC760BE42 PPC907BE UFC760BE43 XVC769AE101 LDMTR-01 UAC389AE02 LTC391AE01 PPC905AE101 UAC383AE01 LDLPTR-01