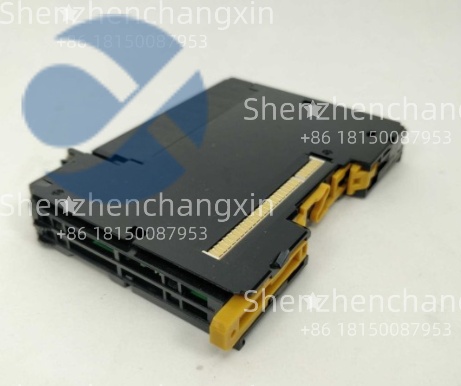

Product Description

The OMRON CQM1H-CPU21is a compact,high-performance Central Processing Unit(CPU)module for the CQM1H series of programmable controllers.It serves as the central brain of the system,executing user-programmed logic,managing built-in and expansion I/O,and handling communication with programming devices and other units.Designed for small to medium-scale machine control and automation applications,it offers a balance of processing power,I/O capacity,and cost-effectiveness.

Application Scenario

In a high-speed automated packaging machine for pharmaceutical blister packs,precise timing between a vacuum picker,a sealing head,and a rejection gate is critical.A delay of even 10 milliseconds can cause misalignment.The machine uses an OMRON CQM1H-CPU21PLC as its main controller.Its fast 0.375µs per basic instruction execution speed allows it to scan a complex ladder logic program controlling 32 I/O points in under 5 milliseconds.During operation,a photoelectric sensor detects a misformed blister.The PLC’s interrupt function,triggered by the sensor input,immediately pauses the main scan,jumps to a dedicated high-speed subroutine programmed in the CQM1H-CPU21,and activates the rejection solenoid within 1 ms.The main cycle then resumes seamlessly.This deterministic,high-speed response,enabled by the CPU’s architecture,ensures defective products are consistently removed without slowing the 120-pack-per-minute line.Furthermore,the CPU’s built-in RS-232C port allows technicians to connect a laptop on the factory floor,monitor real-time I/O status,and force outputs for troubleshooting,minimizing machine downtime.This scenario highlights the CPU’s value in applications requiring fast,deterministic response and easy on-site diagnostics for high-uptime manufacturing.

Key Parameters

Main Parameters

Value/Description

Product Model

OMRON CQM1H-CPU21

Manufacturer

OMRON Corporation

Product Category

Programmable Logic Controller(PLC)CPU Unit

Series

CQM1H Series

Program Capacity

3.2K steps(ladder program)

I/O Capacity

Up to 256 I/O points(with expansion units)

Built-in I/O

Typically includes a fixed number of input/output points(e.g.,16 IN,12 OUT relay/transistor)on the CPU unit itself.

Instruction Execution Speed

Very fast,e.g.,0.375µs per basic instruction(LD).

Data Memory

Sufficient for timers,counters,data registers.

Communication Ports

Built-in RS-232C port for programming(SYSMAC WAY)and peripheral device connection.

Expansion

Supports connection of CQM1H-series I/O and special units via a side connector.

Battery Backup

Supports memory backup with a user-replaceable battery.

Technical Principles and Innovative Values

Integrated I/O and CPU for Space-Efficient Design:The CQM1H-CPU21combines a capable microprocessor with a fixed number of onboard I/O points(often 16 inputs and 12 outputs)in a single,compact unit.This”all-in-one”design eliminates the need for a separate base unit and power supply for small applications,significantly reducing the control panel footprint,part count,and wiring complexity.It represents an optimized solution for standalone machines where a minimal number of I/O points are required,offering a clean and cost-effective architecture.

High-Speed Processing for Responsive Machine Control:At its core is a dedicated microcontroller optimized for executing ladder logic.The fast instruction execution speed ensures that even complex control sequences are scanned rapidly,providing quick response to sensor inputs.This deterministic scan time is crucial for synchronizing mechanical actions in automation equipment.Features like interrupt inputsallow the CPU to immediately respond to critical events(like an emergency stop or a registration sensor)without waiting for the end of the program scan,guaranteeing sub-millisecond reaction times for safety and precision.

Flexible Expansion and Communication Capabilities:Despite its compact size,the CPU is designed for growth.It can be expanded by connecting additional I/O units,analog modules,or communication modules via a simple side connector,allowing the system to be tailored to the application’s needs.The built-in RS-232C port provides a standard interface for programming with OMRON’s CX-Programmer software and for connecting to peripheral devices like bar code readers,weigh scales,or operator interfaces(HMIs),enhancing its versatility in integrated systems.

Application Cases and Industry Value

Case Study:Automotive Component Test Stand Modernization

A manufacturer of fuel injectors operated dozens of legacy test stands with relay-based control.The stands were unreliable,difficult to modify,and provided no data.The company standardized on a retrofit using the OMRON CQM1H-CPU21as the core controller for each stand.The test engineer responsible stated:”The CQM1H-CPU21was the perfect fit.Its built-in I/O handled all the solenoid valves and pressure switches.We used the expansion port to add an analog input module to read a pressure transducer.The programming flexibility let us implement complex test sequences with precise timing that were impossible with relays.Most importantly,the RS-232 port allowed us to connect each stand to a central PC for data logging.We now capture every test result—pressure,flow,timing—for full traceability.The reliability of the PLCs has reduced test stand maintenance by over 80%,and the data has improved our process control dramatically.”This case demonstrates the CPU’s value in modernizing equipment:it replaces unreliable hardware with flexible,software-driven control,enables data collection for quality assurance,and drastically improves overall equipment reliability.

Related Product Combination Solutions

The OMRON CQM1H-CPU21is the center of a CQM1H control system:

CQM1H I/O Expansion Units(e.g.,CQM1H-□□□):Add additional discrete input,output,or mixed I/O points to the system beyond the CPU’s built-in capacity.

CQM1H Special Units:Include analog I/O modules,temperature control units,high-speed counter modules,and serial communication(RS-422/485)modules to extend functionality.

Programming Software(OMRON CX-Programmer):The Windows-based software used to develop,debug,and download the ladder logic program to the CQM1H-CPU21.

Programming Cable(e.g.,CS1W-CN□□□):The cable that connects a PC’s serial port to the CPU’s RS-232C port for programming and online monitoring.

OMRON Operator Interface(HMI)(e.g.,NS Series):Can be connected via the serial port to provide a local operator interface for machine control,status display,and parameter adjustment.

CQM1H Power Supply Unit(if using expansion rack):When using a multi-unit expansion rack,a separate power supply unit is required to power the additional modules.

Installation,Maintenance,and Full-Cycle Support

Installation is straightforward:mount the CPU unit on a DIN rail,connect the main power supply to its terminals,and wire the field devices to its built-in I/O terminals.Expansion units are connected to the side of the CPU.Programming is done via the serial port.A backup battery must be installed to retain the program and data memory when power is off.

Routine maintenance primarily involves checking the status of the CPU’s indicators(RUN,ERROR,COMM)and ensuring the backup battery is replaced periodically(typically every 5 years).The modular design allows for easy replacement of the CPU or I/O units if needed.Our support provides genuine,factory-sourced OMRON CQM1H-CPU21CPU units.We ensure you receive the correct version and can provide technical documentation,including manuals and wiring diagrams.We are committed to supplying reliable components and support to keep your automated equipment running efficiently.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!