Product Overview

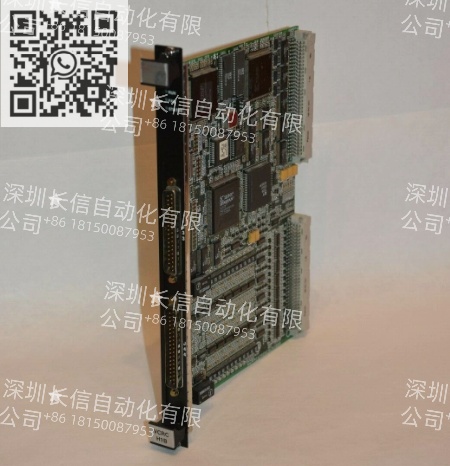

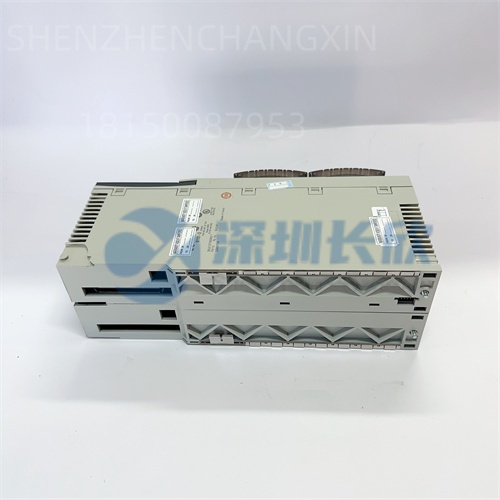

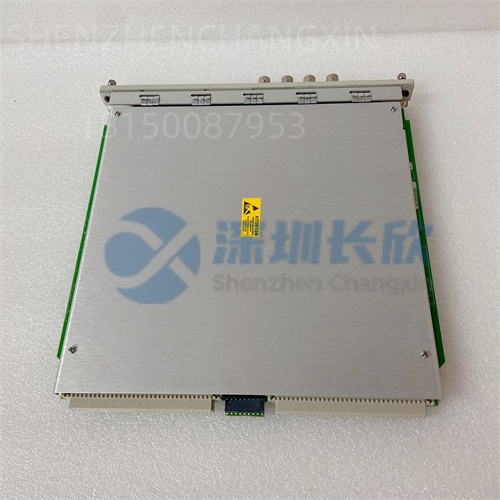

The GE IS200VCRCH1B is a specialized input/output module within the Mark VIe distributed control system(DCS),designed specifically for high-integrity vibration,speed,and position monitoring in critical rotating machinery applications.As part of GE’s Vibration Control Relay(VCR)family,the IS200VCRCH1B serves as the primary interface between field-mounted proximity probes,tachometers,and accelerometers—typically from Bently Nevada—and the Mark VIe turbine control logic.It conditions raw analog signals from sensors,digitizes them with high fidelity,and transmits real-time data to the controller for both operational monitoring and emergency trip decisions.

Deployed extensively in gas turbines,steam turbines,compressors,and generators across power generation and oil&gas facilities,the GE IS200VCRCH1B plays a pivotal role in mechanical protection systems that comply with API 670 and IEC 61508 standards.The module supports up to eight independent sensor inputs and features built-in signal validation,gap voltage monitoring,and fault diagnostics to distinguish between true machinery faults and sensor or wiring issues.This intelligence prevents nuisance trips while ensuring rapid shutdown during genuine overspeed or excessive vibration events.By integrating seamlessly into the Mark VIe architecture—with full redundancy support and deterministic communication—the IS200VCRCH1B delivers the reliability and response speed demanded by modern turbine control environments where milliseconds matter.

Technical Specifications

Parameter Name Parameter Value

Product Model IS200VCRCH1B

Manufacturer General Electric(GE)

Product Type Vibration Control Relay(VCR)I/O Module for Mark VIe

Input Channels 8 differential analog inputs(for proximity probes,accelerometers,or tachometers)

Input Signal Type-24 VDC to 0 V(proximity probe bias),±10 V(accelerometer),TTL/CMOS(speed)

Signal Conditioning Integrated amplifier,filter,and A/D conversion per channel

Communication Interface Dual-redundant Ethernet(SRTP over GEnet)to Mark VIe controllers

Diagnostic Capabilities Gap voltage monitoring,open/short detection,sensor health status

Operating Temperature 0°C to+60°C

Redundancy Support Full hot-swap capable;supports 1oo2 or 2oo3 voting architectures

Power Consumption~15 W(supplied via backplane)

Compliance Standards API 670,IEC 61508(SIL2),CE,UL 61010

Main Features and Advantages

Integrated Sensor Interface for Critical Machinery:The GE IS200VCRCH1B is engineered to directly accept signals from industry-standard Bently Nevada 3300/3500 series proximity probes and accelerometers without external conditioners.Each of its eight channels includes dedicated signal conditioning circuitry that amplifies,filters,and digitizes dynamic vibration and static gap voltage data with high resolution.This eliminates external hardware,reduces cabling complexity,and improves overall system integrity.

Advanced Diagnostics and Fault Discrimination:Unlike basic I/O cards,the IS200VCRCH1B continuously monitors not only vibration amplitude but also probe health through gap voltage trends.If a probe drifts out of range or a cable becomes damaged,the module flags a“sensor fault”rather than triggering a false trip—enhancing availability while maintaining safety.These diagnostics are visible in GE’s ToolboxST software,enabling predictive maintenance.

Seamless Integration with Mark VIe Safety Logic:The IS200VCRCH1B communicates deterministically with redundant Mark VIe controllers via dual GEnet networks.Vibration and speed data are used in real time for both operational display and hardwired trip logic.In overspeed scenarios,the module can initiate a trip command within milliseconds,meeting stringent turbine protection requirements.Its design supports SIL2-certified safety functions when configured in appropriate voting architectures.

Robust,Field-Proven Architecture:Built for harsh turbine hall environments,the IS200VCRCH1B features conformal coating,wide temperature tolerance,and immunity to electrical noise.Its compact form factor fits standard Mark VIe I/O racks,and hot-swap capability allows replacement during operation—minimizing downtime in continuous-process plants.

Application Field

The GE IS200VCRCH1B is predominantly used in power generation and heavy industrial facilities where large rotating equipment must operate safely at high speeds under extreme thermal and mechanical stress.In combined-cycle power plants,the IS200VCRCH1B monitors axial displacement,radial vibration,and rotational speed on gas and steam turbines,feeding data to the Mark VIe system for load control and emergency shutdown.Similarly,in LNG compression trains,it safeguards multi-stage centrifugal compressors by detecting bearing wear or rotor instability before catastrophic failure occurs.

Oil refineries and petrochemical complexes also rely on the IS200VCRCH1B to protect critical drivers such as boiler feedwater pumps,air compressors,and syngas expanders.Here,the module’s ability to differentiate between process-induced vibration(e.g.,surging)and mechanical degradation is crucial for avoiding unnecessary plant trips.Additionally,in hydroelectric and nuclear facilities,the IS200VCRCH1B supports regulatory compliance by providing auditable,high-fidelity machinery health data.Across all these applications,the IS200VCRCH1B acts as the vigilant“nervous system”of the turbine control architecture—ensuring that mechanical anomalies are detected,diagnosed,and acted upon with precision and speed.

Related Products

IS200VCRCG1B:Enhanced version of the VCR module with updated firmware and improved EMI shielding;backward compatible with IS200VCRCH1B.

IS200SPROH1B:Speed and Position Reference Output module,often paired with IS200VCRCH1B for full turbine sensing coverage.

IS200TVIBH1B:Dedicated Turbine Vibration Input module for non-redundant Mark VIe applications;fewer channels but lower cost.

Mark VIe Controller(IC698CPU301):Primary control processor that interfaces with IS200VCRCH1B via GEnet for real-time machinery protection.

ToolboxST Software:GE’s engineering suite used to configure,calibrate,and diagnose IS200VCRCH1B modules and entire Mark VIe systems.

Bently Nevada 3300 XL Probes:Industry-standard eddy-current sensors commonly connected directly to the IS200VCRCH1B input terminals.

IS200TRGLH1B:Trip Relay Logic module that receives trip commands from IS200VCRCH1B-processed logic to energize final output relays.

Installation and Maintenance

Pre-installation preparation:Prior to installing the GE IS200VCRCH1B,confirm compatibility with the existing Mark VIe I/O rack and ensure redundant GEnet communication paths are active.Verify that all proximity probe cables are shielded twisted-pair with proper grounding at the controller end only.Use GE-recommended terminal blocks and torque specifications to secure sensor wiring,and validate that probe gap settings match OEM specifications before powering the module.The IS200VCRCH1B must be configured in ToolboxST with correct channel types(vibration,speed,or position)and alarm/trip thresholds prior to commissioning.

Maintenance recommendations:Routine maintenance of the IS200VCRCH1B involves reviewing diagnostic logs in ToolboxST for gap voltage drift,noise levels,or intermittent faults that may indicate aging sensors or loose connections.Perform annual calibration checks using a signal simulator to verify trip setpoints.The module supports hot swapping in redundant systems—always follow GE’s lockout/tagout procedures if redundancy is not implemented.Store spare IS200VCRCH1B units in static-safe,climate-controlled packaging to preserve electronic components and conformal coating integrity.

Product Guarantee

We guarantee that every GE IS200VCRCH1B module we supply is authentic,new-in-box(or professionally refurbished to OEM standards),and fully tested on live Mark VIe hardware.Each unit undergoes functional verification of all eight input channels,communication handshake with redundant controllers,and diagnostic response simulation.We provide a 12-month warranty against manufacturing defects and offer lifetime technical support from engineers certified in GE Mark VIe systems.Should your IS200VCRCH1B exhibit any performance anomaly,we will assist with troubleshooting or expedite a replacement to ensure your turbine protection system remains uncompromised.Our commitment is to deliver not just a spare part,but a mission-critical component you can trust with your most valuable assets.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!