📄 Description

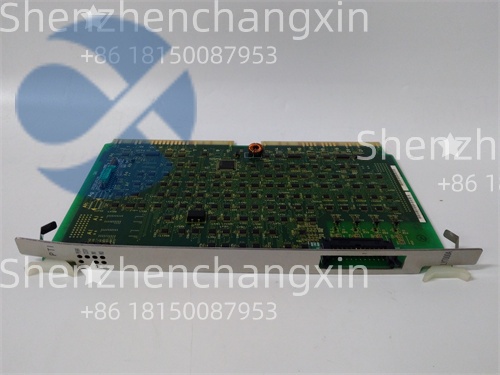

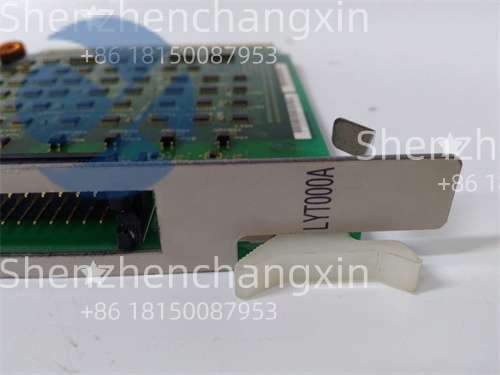

The Hitachi LYT000A is a compact, high-efficiency AC variable frequency drive (VFD) from Hitachi’s industrial automation portfolio, designed for precise speed and torque control of 3-phase induction motors from 0.4 kW to 7.5 kW (depending on model suffix). Part of the LYT series, this inverter combines sensorless vector control, robust protection features, and user-friendly setup in a space-saving design—making it ideal for applications such as conveyors, pumps, fans, mixers, compressors, and machine tools.

Engineered for global compliance, the LYT000A includes built-in EMC filters, Safe Torque Off (STO) per IEC 61800-5-2. and communication capabilities via Modbus RTU (RS-485)—enabling seamless integration into PLC-based control systems or building management platforms.

⚠️ Note: “LYT000A” is a base model prefix—actual part numbers include suffixes indicating voltage, power rating, and enclosure (e.g., LYT000A2024UL = 200–240 V, 2.2 kW, UL-listed).

🏭 Application Scenario

At a Japanese beverage bottling plant, inconsistent label alignment on high-speed filling lines was traced to motor speed drift in aging mechanical gearboxes. By retrofitting main conveyor drives with Hitachi LYT000A inverters, engineers enabled closed-loop speed regulation using sensorless vector control. The built-in PID function maintained constant tension based on encoder-less feedback, while Modbus RTU reported energy consumption to the central SCADA. Label misalignment dropped by 95%, and annual electricity costs fell by $ 18.000 per line. Here, the LYT000A wasn’t just a drive—it was a precision motion enabler.

⚙️ Key Parameters (Typical for LYT000A Series)

表格

💡 Technical Innovations & Value

Innovation 1: True Plug-and-Play Auto-Tuning

The LYT000A automatically identifies motor parameters during first run—optimizing vector control without external sensors or complex setup.

Innovation 2: Built-In Safety & Energy Intelligence

STO eliminates need for external contactors in safety circuits, while energy monitoring functions support ISO 50001 compliance.

Innovation 3: Compact Design with Full Functionality

Despite its small footprint (e.g., 130 x 100 x 150 mm for 2.2 kW), it includes braking transistor, EMC filter, and communication—reducing BOM cost.

Innovation 4: Application-Specific Macros

Pre-configured settings for pump, fan, conveyor, and hoist applications accelerate commissioning.

🌐 Industry Applications

Water/Wastewater: Constant pressure pump control with sleep/wake function

HVAC: Fan speed modulation based on CO₂ or temperature

Material Handling: Smooth acceleration/deceleration on conveyors

Food & Beverage: Hygienic speed control for mixers and fillers

Machine Tools: Spindle control with rapid stop via DC braking

In a Korean semiconductor fab, LYT000A drives controlled exhaust fans in cleanrooms. Their low acoustic noise (<65 dB) and stable airflow met strict contamination standards—while STO ensured safe maintenance access.

🔗 Related Product Solutions

Hitachi WJ200 Series: Higher-power successor (up to 110 kW) with advanced networking

Hitachi HX Series: Legacy series (LYT replaces HX in new designs)

Braking Resistors: Required for frequent deceleration (e.g., BR100-200W)

Keypad Remote Mount Kit: For front-panel operation (e.g., OP-HL01)

Communication Adapters: PROFINET, EtherNet/IP (via third-party gateways)

Motor Cables: Shielded, VFD-rated cables to reduce EMI

🔧 Installation & Maintenance

Installation requires:

Proper grounding (critical for EMC)

Sizing of input fuses/circuit breakers

Connection of motor leads directly to drive terminals

Optional RS-485 daisy-chaining for multi-drive networks

Maintenance is minimal—no fans or consumables. The drive self-diagnoses faults (e.g., “OC” = overcurrent) and logs last trip data. Firmware updates are rarely needed but possible via keypad or software.

We supply genuine Hitachi LYT000A units (with full suffixes confirmed) with:

Factory calibration certificate

Functional test under load

12-month warranty

Compatibility verification with your motor specs

✅ Conclusion

The Hitachi LYT000A delivers industrial-grade performance, safety compliance, and energy efficiency in a compact, cost-effective package. Whether you’re optimizing an existing system or designing new machinery, this inverter provides reliable motor control with future-ready connectivity.