Description

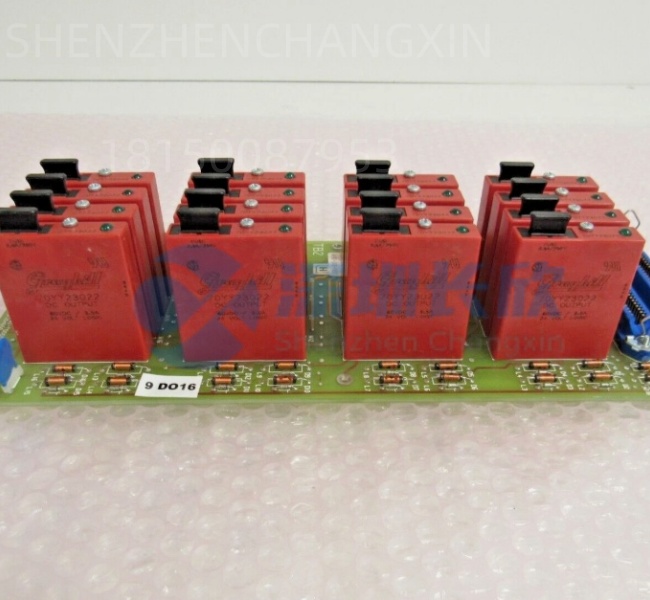

The Honeywell 51304650-100 is a high-density Field Terminal Assembly (FTA) module, specifically configured as a Digital Output (DO) module, manufactured by Honeywell for its distributed control systems (DCS). It serves as a critical interface, translating control logic commands into actionable electrical signals to operate field devices like solenoid valves, motor starters, and alarms with precision and reliability.

Application Scenarios

Imagine the control room of a large, continuous-process chemical plant. A reactor’s temperature is climbing towards a dangerous setpoint. The safety logic processed by the Experion controller determines that a cooling water valve must open immediately. This critical command is sent to the Honeywell 51304650-100 module installed in a remote marshalling cabinet. Within milliseconds, one of its 16 robust output channels energizes, sending a solid 24VDC signal to the valve’s solenoid, initiating cooling and averting a potential shutdown or safety incident. This scenario exemplifies the core duty of the 51304650-100: providing the final, reliable physical action in a control loop. It addresses the pain points of signal integrity, density, and durability in environments where a single failed output can cost thousands per minute in lost production.

Technical Principles and Innovative Values

Innovation Point 1: High-Density, High-Drive Capacity in a Rugged Package. The Honeywell 51304650-100 packs 16 independently isolated output channels into a single module. Each channel is capable of driving substantial loads (typically up to 2A), allowing it to directly control many field devices without the need for intermediate relays. This design maximizes cabinet space utilization while providing the muscle needed for direct control, simplifying system architecture and reducing points of failure.

Innovation Point 2: Enhanced System Integrity through Galvanic Isolation. Each output channel is electrically isolated from the others and from the sensitive control-side electronics. This is a critical innovation. It prevents a fault on one field device (e.g., a short circuit or voltage spike) from cascading back to damage other channels or the central controller. This isolation ensures system-wide stability and protects valuable control assets, a key differentiator in mission-critical processes.

Innovation Point 3: Integrated Diagnostics for Predictive Maintenance. The module goes beyond simple switching. It incorporates circuitry to monitor the health of each output channel. It can detect conditions like open load (broken wire) or short-circuit faults. These diagnostics are communicated back to the control system, allowing operators and maintenance teams to receive early warnings of impending issues before they cause a process failure, enabling a shift from reactive to predictive maintenance.

Application Cases and Industry Value

Case Study: Offshore Gas Production Platform. A major operator was experiencing intermittent, unexplained trips on emergency shutdown (ESD) valves, leading to costly production halts. Investigation pointed to unreliable output signals from older-generation modules susceptible to moisture and electrical noise. The platform standardized on the Honeywell 51304650-100 module for all critical valve control points during a control system upgrade. The module’s robust environmental specs (-40°C to +85°C) withstood the harsh marine atmosphere, and its superior electrical noise immunity eliminated the spurious trips. The platform manager reported a 15% reduction in unplanned downtime in the first year directly attributed to improved output reliability, stating the new modules provided “rock-solid control when it mattered most.”

Related Product Combination Solutions

Process Module (e.g., PM/APM series): These are the I/O processors that manage groups of FTA modules like the 51304650-100. providing the intelligent interface back to the main controller.

Analog Input FTA Modules (e.g., 51304353-xxx): Used in the same I/O subsystem to bring in signals from temperature, pressure, and flow transmitters, completing the sensor-to-control-to-actuator loop.

Digital Input FTA Modules (e.g., 51304476-xxx): Companion modules for reading field switch contacts, pushbuttons, and status signals, providing the input side to the controller’s logic.

Redundant I/O Link Controllers: For high-availability applications, these controllers ensure continuous communication to the 51304650-100 even if the primary path fails.

Honeywell Experion C300 Controller: The primary control engine that executes the logic sending commands to the 51304650-100.

Installation, Maintenance, and Full-Cycle Support

Installation of the Honeywell 51304650-100 is designed for efficiency. It mounts securely on a standard DIN rail within a system cabinet. The use of clearly marked, removable terminal blocks makes field wiring straightforward and allows for easy replacement without disturbing other connections. Prior to installation, ensure the system power is disabled and verify the module’s address or slot assignment matches the controller’s configuration.

Routine maintenance is greatly simplified by the module’s built-in diagnostics. Engineers should regularly review system alerts related to the I/O subsystem. The module’s LEDs provide immediate visual status. If a fault is isolated to the module, replacement is a simple process of powering down the local I/O segment (or leveraging hot-swap support if configured), swapping the module, and confirming its auto-recognition by the system. We provide comprehensive full-cycle support, from initial system design consultation to ensure proper integration, supply of guaranteed genuine spare parts, and 24/7 technical support for urgent troubleshooting. Our commitment is to ensure your control system’s output layer remains as reliable as the logic behind it.