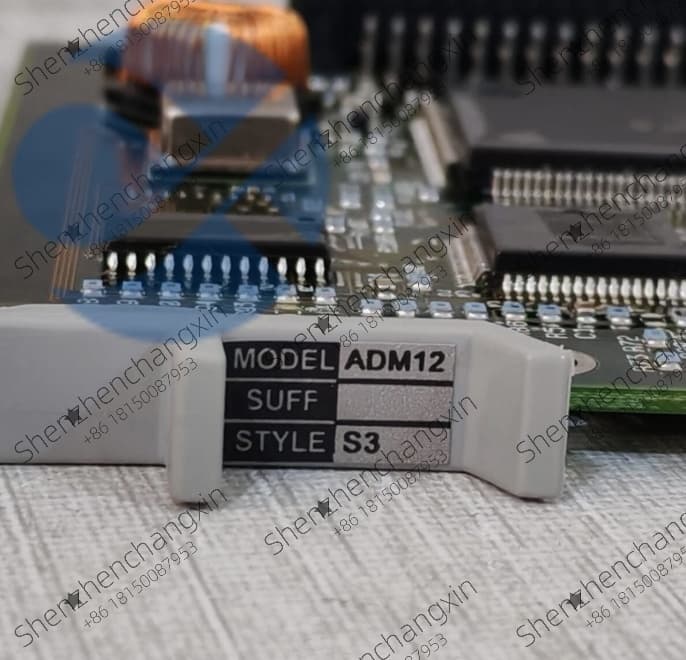

Description

The YOKOGAWA ADM12 S3 is a 16-channel analog input module designed for use in Yokogawa’s CENTUM VP and CENTUM CS 3000 distributed control systems (DCS). It provides high-precision acquisition of standard industrial signals—primarily 4–20 mA current loops—from field devices such as pressure transmitters, temperature sensors (via RTD/mV converters), flow meters, and level gauges.

Engineered for reliability in harsh process environments, the ADM12 S3 features channel-to-channel isolation, built-in open-wire detection, HART digital communication support, and robust surge protection. As part of Yokogawa’s modular Remote I/O (RIO) or Field Control Station (FCS) architecture, it enables accurate, real-time process data to flow securely into the control logic layer—ensuring stable, efficient, and safe plant operation.

Application Scenarios

At a LNG export terminal in Australia, inconsistent tank level readings caused repeated false high-level alarms, triggering unnecessary production holds. Investigation revealed aging analog cards with drifting zero points. After upgrading to YOKOGAWA ADM12 S3 modules, engineers leveraged the card’s ±0.1% accuracy and open-wire diagnostics. Within days, signal stability improved by 70%, and nuisance alarms vanished. During commissioning, HART pass-through allowed technicians to calibrate smart transmitters directly through the DCS—cutting loop-check time in half. For the automation lead, the ADM12 S3 wasn’t just an I/O card; it was the key to operational trust.

Parameter

表格

Technical Principles and Innovative Values

Innovation Point 1: True 16-Channel Density Without Compromise

Unlike older 8-channel cards, the ADM12 S3 doubles I/O density while maintaining full channel isolation and diagnostic depth—reducing cabinet footprint, power consumption, and cost per point by up to 40%.

Innovation Point 2: Advanced Open-Wire Detection

The module injects a small test current to detect broken wires or disconnected transmitters—even when the loop is at 4 mA—enabling predictive maintenance before process drift occurs.

Innovation Point 3: Native HART Multiplexer Integration

Through Yokogawa’s HART MUX option, multiple ADM12 S3 modules can share a single HART communication path, allowing asset management software (e.g., PRM) to access device health data without extra wiring.

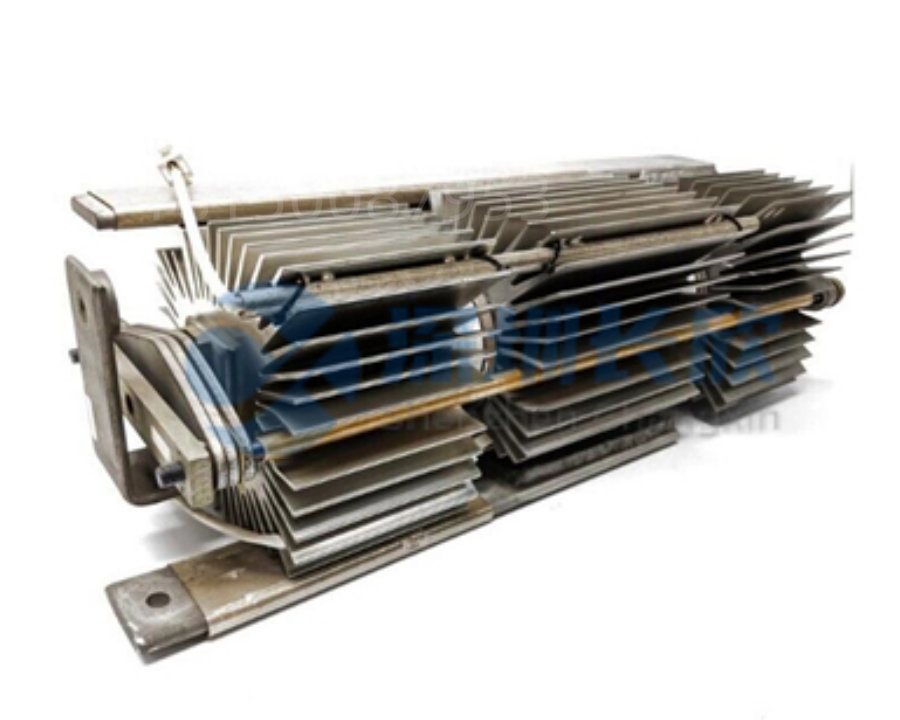

Innovation Point 4: Fail-Safe Design with Surge Immunity

Each channel includes TVS diodes and filtering compliant with IEC 61000-4-5 (4 kV surge), making the ADM12 S3 suitable for outdoor or lightning-prone installations.

Application Cases and Industry Value

A petrochemical cracker in South Korea retrofitted its reactor temperature monitoring system using ADM12 S3 modules. With 16 RTD-to-mA transmitters per card, they reduced I/O cabinet count from 12 to 5. The built-in diagnostics flagged a failing thermowell sensor during routine operation—preventing a potential runaway reaction. Over three years, mean time between failures (MTBF) for the AI layer exceeded 150.000 hours.

In a European biopharma facility, the ADM12 S3’s low noise and high resolution enabled precise pH and dissolved oxygen control in sterile fermenters. Batch consistency improved by 18%, directly impacting product yield and regulatory compliance.

Related Product Combination Solutions

AAI143: Analog Input Module Base – houses ADM12 S3 in CENTUM I/O nodes

AMM12T: Thermocouple Input Module – complements ADM12 S3 for direct temp sensing

ADV12D: Digital Output Module – pairs for complete control loops

Field Control Station (FCS): e.g., STARDOM or CENTUM VP FCS – processes data from ADM12 S3

Yokogawa PRM (Plant Resource Manager): Asset management software – uses HART data from ADM12 S3

HART MUX Unit: Enables multi-device HART communication over single channel

Power Supply Module (e.g., CPS11): Provides regulated power to I/O node

Redundant I/O Backplane: Supports hot-swap and failover for critical applications

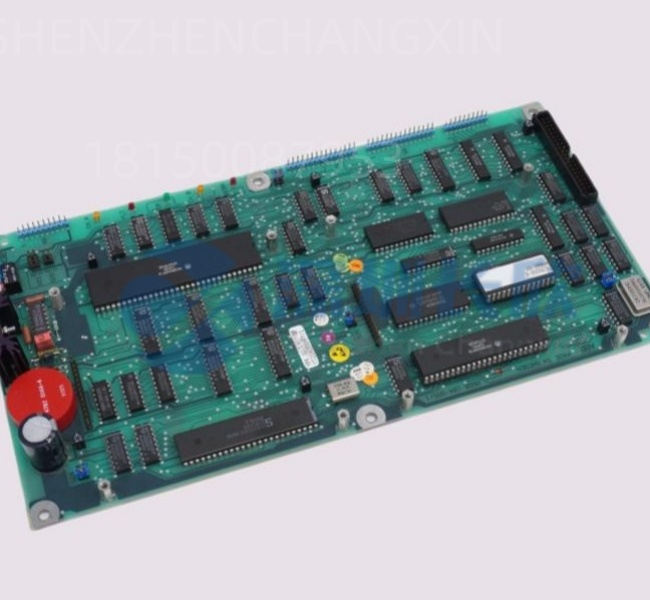

Installation, Maintenance, and Full-Cycle Support

Installing the YOKOGAWA ADM12 S3 involves inserting it into a powered AAI143 carrier on a DIN rail within a CENTUM I/O node. Field wiring connects to removable screw terminals (14–22 AWG). For optimal noise immunity, use twisted-pair shielded cable with single-point grounding at the controller end.

During commissioning:

Use Engineering Tool (e.g., HIS or Exaopc) to assign tags, scaling, and alarm limits

Enable HART pass-through if using smart transmitters

Perform loop tests via software forcing or mA simulator

Maintenance is simplified by per-channel LEDs and integrated diagnostics visible in the DCS alarm summary. No calibration is required—the ADM12 S3 is factory-trimmed and drift-stable over temperature.

We supply only genuine YOKOGAWA ADM12 S3 modules—either new from Yokogawa distribution or professionally refurbished with full functional validation, including:

Input accuracy verification (±0.1%)

Open-wire detection test

HART communication check

LED and isolation integrity

Each unit includes a certificate of conformance and compatibility assurance for your CENTUM system revision. Our team offers configuration templates, migration support from legacy Yokogawa I/O (e.g., AMM11T), and 24/7 technical assistance from certified CENTUM engineers.