Product Overview

The GE IS220PRTDH1A is a specialized dual-channel resistance temperature detector(RTD)input terminal module engineered for mission-critical temperature monitoring in heavy-duty industrial turbine control systems.As an integral component of the Mark VIe and Mark VIeS distributed control platforms—now maintained by Emerson Automation Solutions following its acquisition of GE’s automation business—the GE IS220PRTDH1A delivers high-fidelity,real-time temperature data from PT100 sensors installed on bearings,exhaust manifolds,steam casings,and other thermally sensitive zones of gas and steam turbines.This module plays a pivotal role in both operational efficiency and functional safety,feeding precise thermal readings into the controller to enable predictive maintenance,performance optimization,and,when necessary,rapid trip actions to prevent catastrophic mechanical failure.

Designed for seamless integration within the I/O architecture of the Mark VIe system,the GE IS220PRTDH1A supports 3-wire PT100 configurations with built-in lead-wire resistance compensation,ensuring measurement accuracy even over long cable runs typical in power plant environments.Each of its two independent channels features galvanic isolation and dedicated signal conditioning circuitry,minimizing cross-channel interference and enhancing noise immunity in electrically harsh settings.The GE IS220PRTDH1A is not merely a data acquisition device—it is a frontline guardian of turbine integrity,trusted in thousands of installations worldwide where reliability,precision,and compliance with functional safety standards are non-negotiable.

Technical Specifications

Parameter Name Parameter Value

Product Model IS220PRTDH1A

Manufacturer GE→Emerson Automation Solutions

Product Type Dual-channel RTD Input Terminal Module

Input Channels 2 independent channels

Supported Sensor Types PT100(IEC 60751 Class A/B),PT1000,NI120(configurable)

Wiring Configuration 3-wire RTD with automatic lead compensation

Measurement Range–200°C to+850°C(sensor-dependent;typical use:–50°C to+500°C)

Resolution 0.1°C

Accuracy(Typical)±0.1°C with Class A PT100 and calibration

Isolation Voltage≥500 Vrms(channel-to-backplane)

Communication Interface Proprietary I/O Pack bus(via terminal base,e.g.,IS200VATDH1A)

Operating Temperature 0°C to+60°C

Certifications Compliant with IEC 61508 SIL 3(within Mark VIeS safety architecture),CE,UL

Main Features and Advantages

High-Precision Thermal Monitoring:The IS220PRTDH1A leverages advanced analog front-end circuitry and 16-bit A/D conversion to deliver laboratory-grade temperature resolution in industrial field conditions.Its support for 3-wire PT100 sensors eliminates errors caused by cable resistance—a common issue in large-scale power plants—ensuring that the controller receives true process values rather than distorted signals.

Functional Safety Integration:Within the Mark VIeS safety framework,the IS220PRTDH1A contributes to SIL 3-compliant protection logic.It enables redundant sensor strategies(e.g.,2oo2 voting)for critical points like turbine bearings,where a single overheating event could trigger a forced outage or equipment loss.The module continuously performs self-diagnostics,detecting open circuits,short circuits,and out-of-range conditions,then reporting faults directly to the control system for immediate operator awareness.

Seamless System Compatibility:Designed exclusively for the Mark VIe ecosystem,the IS220PRTDH1A integrates effortlessly with Emerson’s ToolboxST engineering suite.Engineers can configure sensor types,alarm thresholds,and engineering units without hardware changes.Once installed in its companion terminal base(such as IS200VATDH1A),the module is auto-detected,reducing commissioning time and eliminating configuration mismatches.Its robust construction—featuring conformal coating and industrial-grade components—ensures decades of reliable service in environments with high humidity,vibration,and EMI.The IS220PRTDH1A thus combines metrological rigor with operational resilience,making it indispensable for modern turbine control and protection.

Application Field

The IS220PRTDH1A is predominantly deployed in power generation facilities where gas and steam turbines form the core of energy production.In combined-cycle power plants,it monitors exhaust gas temperatures across multiple stages of GE Frame 7EA or 9FA turbines,providing essential feedback for combustion tuning and thermal stress management.Similarly,in steam turbine applications—such as those driving generators in coal or nuclear plants—the IS220PRTDH1A tracks casing metal temperatures and bearing oil inlet/outlet differentials to prevent thermal bowing or lubrication failure.

Beyond utility-scale generation,the IS220PRTDH1A is widely used in industrial cogeneration and mechanical drive applications.Oil and gas facilities employ it on compressor-driven turbines in LNG trains or pipeline booster stations,where unplanned downtime carries severe financial and safety consequences.Petrochemical complexes rely on the IS220PRTDH1A for monitoring back-pressure steam turbines used in refining processes,ensuring compliance with strict operational envelopes.Even in emerging applications like hydrogen-ready turbine retrofits,this module remains relevant due to its adaptability and proven track record.Wherever precise,reliable,and safety-certified temperature data is required to protect multi-million-dollar rotating assets,the IS220PRTDH1A stands as a trusted solution in the global installed base of Mark VIe-controlled machinery.

Related Products

IS200VATDH1A:Dedicated terminal base for IS220PRTDH1A,providing field wiring terminals and mechanical/electrical interface to the I/O pack

IS220PTURH1A:Thermocouple input module for Mark VIe,complementary to IS220PRTDH1A for high-temperature exhaust measurements

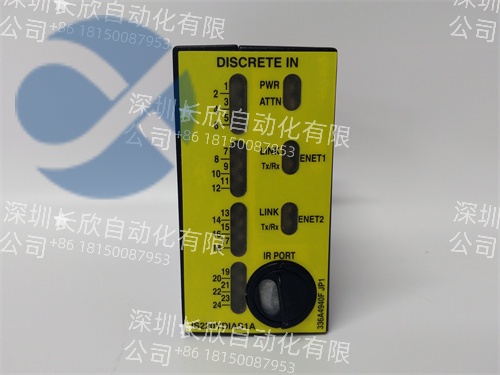

IS220PDIAH1A:Discrete input terminal module used alongside IS220PRTDH1A in turbine protection panels

VCMIH:Mark VIe controller I/O interface card that communicates with IS220PRTDH1A via the I/O pack network

VPRO:Mark VIeS safety processor that utilizes data from IS220PRTDH1A for SIL-rated trip logic execution

IS220PRTDH2A:Enhanced version with improved diagnostics or updated firmware(if released by Emerson)

IC697CPU788:GE Series 90-70 CPU(legacy alternative platform,not directly compatible but used in older turbine controls)

Installation and Maintenance

Pre-installation preparation:Before installing the IS220PRTDH1A,verify compatibility with the target I/O pack and confirm that the terminal base(typically IS200VATDH1A)is securely mounted on a DIN rail within a properly grounded Mark VIe I/O cabinet.Ensure all field wiring uses shielded,twisted-pair cable rated for industrial environments,and route sensor leads away from high-voltage or variable-frequency drive cables to minimize electromagnetic interference.Confirm that PT100 sensors are Class A or B compliant and that lead lengths are balanced per channel to maximize compensation effectiveness.

Maintenance recommendations:The IS220PRTDH1A requires minimal routine maintenance but benefits from periodic validation during scheduled outages.Use a precision resistance calibrator to simulate PT100 values at key points(e.g.,0°C,100°C,300°C)and verify readings in ToolboxST against expected engineering units.Inspect terminal screws for proper torque(typically 0.5–0.6 N·m)and check for signs of corrosion or overheating.If the module reports persistent“Open Circuit”or“Sensor Fault”alarms despite verified wiring,replace the IS220PRTDH1A as internal signal conditioning components may have degraded.Always power down the I/O pack before removal to avoid backplane damage.

Product Guarantee

Every IS220PRTDH1A supplied undergoes rigorous functional testing,including dual-channel RTD simulation,isolation verification,and communication handshake with Mark VIe I/O infrastructure.We guarantee that each unit is either new-in-box from Emerson-authorized channels or professionally refurbished to meet original factory specifications.The IS220PRTDH1A comes with a full 12-month warranty covering material and workmanship defects,backed by direct access to senior-level Mark VIe system engineers for troubleshooting and integration support.Our commitment ensures that your turbine protection system operates with the integrity and reliability demanded by modern power generation—because when it comes to safeguarding critical rotating equipment,only genuine,thoroughly validated components should ever be trusted.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!