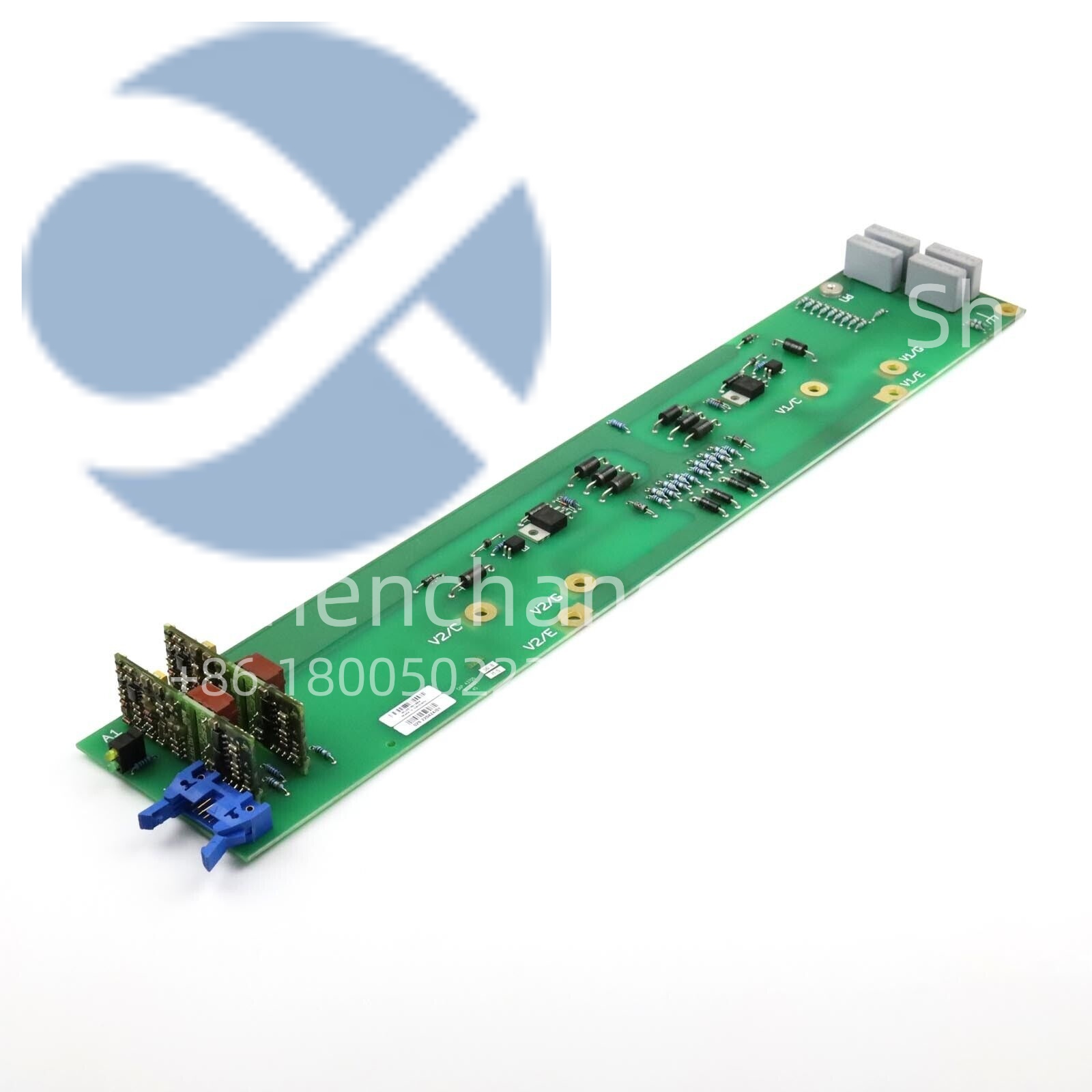

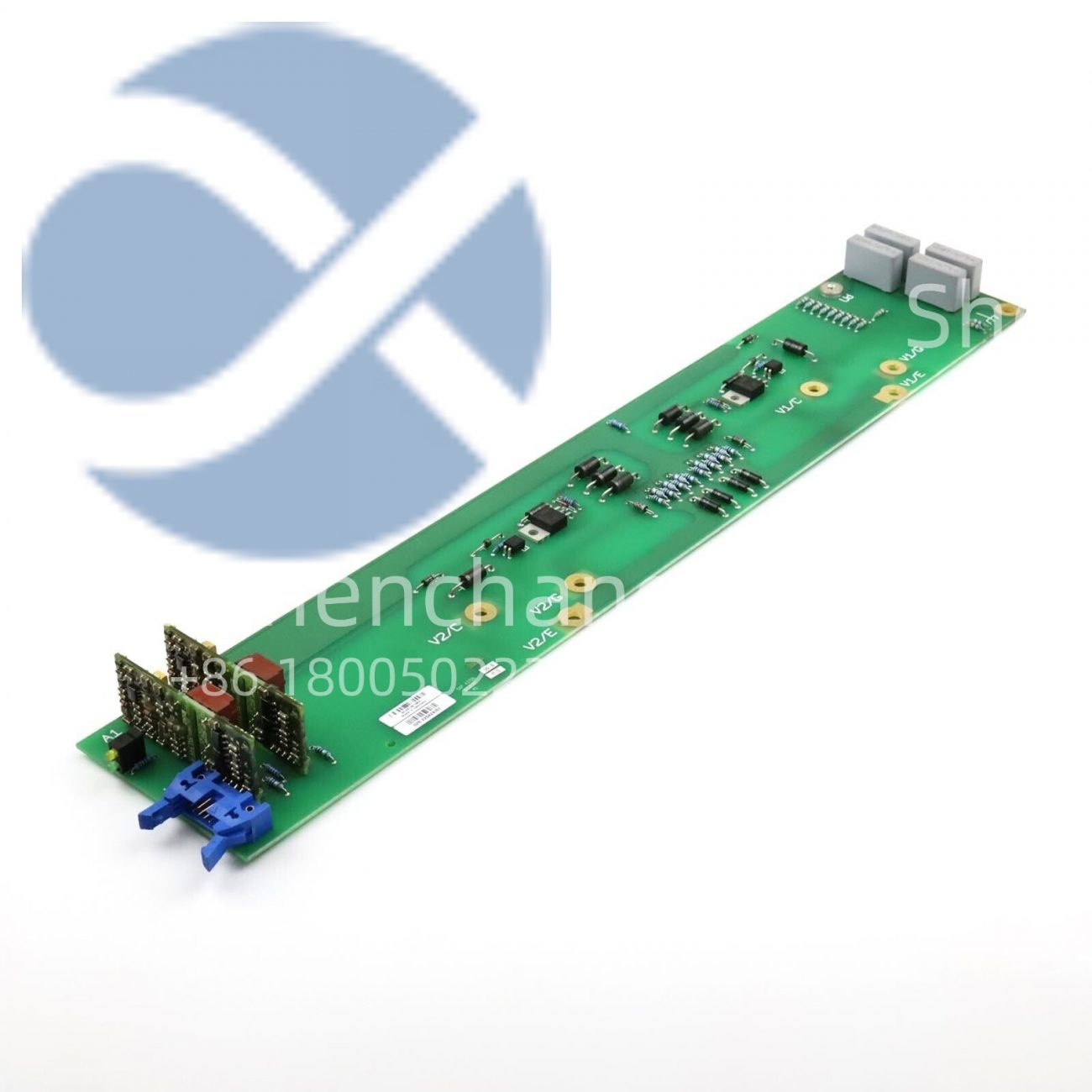

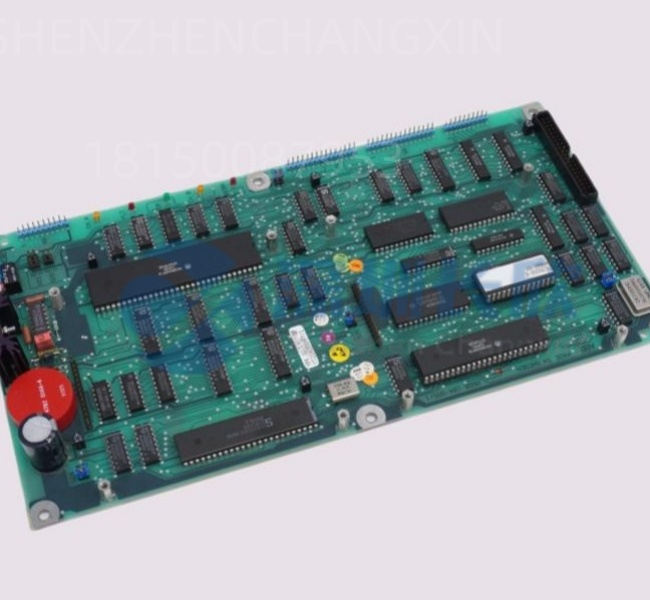

Product Overview

The ALTOM MD2000 029.220424 is a dedicated industrial control module designed by ALTOM,a specialist in industrial automation components,engineered to deliver precise signal processing and equipment control for small-to-medium industrial automation applications.Unlike generic control modules,ALTOM MD2000 029.220424 is tailored to bridge the gap between field sensors/actuators and upper-level control systems(e.g.,PLCs,DCS),focusing on reliable parameter regulation and real-time signal interaction—making it a critical component for machines requiring stable,accurate control,such as packaging equipment,small-scale production lines,or environmental control systems.

As a core control unit,ALTOM MD2000 029.220424 integrates multi-type signal support,including analog input/output for continuous parameter monitoring(e.g.,temperature,pressure)and digital input/output for discrete control tasks(e.g.,motor on/off,valve switching).Its compact design ensures easy installation in space-constrained control cabinets,while its compatibility with standard industrial communication protocols enables seamless integration into existing automation ecosystems.Whether deployed in food processing plants for temperature control,water treatment skids for flow regulation,or HVAC systems for environmental management,ALTOM MD2000 029.220424 ensures consistent equipment performance,reduces operational errors,and minimizes unplanned downtime—delivering long-term value for small-scale automation projects.

Technical Specifications

Parameter Name

Parameter Value

Product Model

ALTOM MD2000 029.220424

Manufacturer

ALTOM

Product Type

Industrial Automation Control Module(Signal Processing&Parameter Control)

Signal Support

Analog Input(AI):4 channels(4-20mA DC/0-10V DC);Analog Output(AO):2 channels(4-20mA DC/0-10V DC);Digital Input(DI):8 channels(24VDC);Digital Output(DO):4 channels(24VDC,1A per channel)

Measurement Accuracy

Analog signals:±0.1%full scale;Digital signals:Response time≤1ms

Communication Protocol

RS485(Modbus RTU)

Power Supply

DC 24V±10%(typical current:0.3A)

Operating Temperature Range

-10°C to+60°C(no derating)

Storage Temperature Range

-40°C to+85°C

Protection Level

IP20(module body);IP40(with optional protective cover)

Isolation Level

1kVrms(signal channels to power supply);0.5kVrms(channel-to-channel)

Physical Dimensions(W×H×D)

100mm×150mm×75mm(fits 35mm DIN rail)

Weight

Approximately 0.4kg

Certifications

CE,RoHS,IEC 61000-6-2(EMC)

Programming Interface

Via Modbus RTU(using standard configuration software)

Output Protection

Overcurrent protection(DO channels);Short-circuit protection

LED Indicators

16 total(power,communication status,I/O channel activation)

Terminal Type

Removable screw terminals(max.1.5mm²wire size)

Operating Humidity

5%to 95%(non-condensing)

Main Features and Advantages

Multi-signal compatibility for versatile control:ALTOM MD2000 029.220424 supports both analog and digital signals,eliminating the need for multiple single-function modules.With 4 AI channels for continuous parameters(e.g.,a 4-20mA pressure sensor)and 8 DI channels for discrete status(e.g.,a 24VDC limit switch),it can handle mixed control tasks—such as a packaging machine that monitors film tension(analog)and triggers seal activation(digital).This versatility reduces cabinet space usage by 30%compared to using separate analog and digital modules,simplifying system layout and wiring.

High accuracy for precise parameter regulation:The module’s analog signal accuracy of±0.1%full scale ensures reliable measurement and control of critical parameters.For example,in a small-scale chemical mixing process,ALTOM MD2000 029.220424 maintains a temperature setpoint within±0.2°C(when paired with a Pt100 sensor),preventing batch inconsistencies that often occur with lower-accuracy modules(±0.5%or more).This precision improves product quality and reduces material waste,delivering measurable cost savings over time.

Easy integration and configuration:ALTOM MD2000 029.220424 uses the industry-standard Modbus RTU protocol,enabling plug-and-play compatibility with most PLCs(e.g.,Siemens S7-1200,ABB AC500)and HMI panels.Configuration is simplified via standard Modbus software—users can set I/O ranges,alarm thresholds,and communication parameters without specialized programming skills.A small food processing plant,for instance,was able to integrate the module into its existing PLC system in under 2 hours,compared to 6+hours for proprietary modules.

Robust design for industrial durability:Engineered to withstand harsh industrial conditions,ALTOM MD2000 029.220424 operates from-10°C to+60°C and meets IEC 61000-6-2 EMC standards,protecting against electromagnetic interference from nearby motors or frequency converters.Its DO channels include overcurrent protection,which shuts down output if a short circuit occurs(e.g.,a faulty valve coil),preventing module damage.Field data shows the module has a mean time between failures(MTBF)of over 50,000 hours,ensuring reliable operation in 24/7 production environments.

Application Field

ALTOM MD2000 029.220424 is well-suited for small-to-medium industrial automation scenarios where versatile,accurate control is required.In food and beverage manufacturing,it controls standalone equipment like filling machines—using 2 AI channels to monitor liquid level and flow rate,and 2 DO channels to activate fill valves and conveyor belts.For example,a craft brewery used ALTOM MD2000 029.220424 to regulate beer filling pressure,reducing fill volume variation from±5%to±1%and cutting product waste by 800 liters monthly.

In environmental control systems,such as small water treatment skids or laboratory air purification units,the module manages critical parameters.A wastewater treatment company deployed ALTOM MD2000 029.220424 to monitor pH levels(via 1 AI channel)and control chemical dosing pumps(via 1 AO channel),ensuring effluent meets regulatory standards.The module’s EMC resilience prevented interference from nearby pump motors,eliminating the false alarms that previously disrupted operation.

ALTOM MD2000 029.220424 also excels in building automation,particularly for HVAC zone control in small commercial spaces(e.g.,offices,retail stores).It uses 2 AI channels to measure temperature and humidity,and 4 DI/DO channels to control fan speed and damper position.A retail chain integrated the module into 50 store locations,reducing HVAC energy consumption by 15%by optimizing airflow based on real-time occupancy(detected via DI-connected motion sensors).Its compact size allowed installation in existing building control panels,avoiding costly cabinet upgrades.

Related Products

ALTOM MD2000 029.220425:Upgraded variant of ALTOM MD2000 029.220424 with expanded I/O(6 AI/4 AO/12 DI/6 DO),ideal for scaling from small to medium systems.

ALTOM MD1000 029.220310:Compact analog-only module(6 AI/3 AO)complementary to ALTOM MD2000 029.220424 for applications requiring only continuous parameter control.

ALTOM RS485-ETH Converter:Communication adapter for ALTOM MD2000 029.220424;converts RS485 to Ethernet(Modbus TCP)for integration into networked SCADA systems.

Sick T4000:Temperature sensor paired with ALTOM MD2000 029.220424;provides 4-20mA output for precise temperature monitoring in industrial processes.

Phoenix Contact QUINT-PS/1AC/24DC/1.2:24VDC power supply tailored for ALTOM MD2000 029.220424;delivers stable power in voltage-fluctuating industrial environments.

ALTOM Config Tool:Free software for ALTOM MD2000 029.220424;enables easy configuration of I/O parameters,alarm thresholds,and communication settings.

Weidmüller 1794670000:Terminal block accessory for ALTOM MD2000 029.220424;simplifies wiring and provides additional surge protection in high-EMI environments.

ALTOM MD2000 Protective Cover:IP40-rated cover for ALTOM MD2000 029.220424;shields the module from dust and water splatter in harsh industrial settings.

Installation and Maintenance

Pre-installation preparation:Before installing ALTOM MD2000 029.220424,confirm the application’s signal requirements(e.g.,number of analog/digital channels)match the module’s specifications.Inspect the module for physical damage(cracked housing,bent terminals)and verify the installation location meets the operating temperature(-10°C to+60°C)and humidity(5-95%non-condensing)limits.Gather tools:small torque screwdriver(for terminal wiring),wire strippers,and a multimeter(to test power and signal continuity).

Installation steps:Mount ALTOM MD2000 029.220424 on a 35mm DIN rail in the control cabinet,ensuring at least 10mm clearance from adjacent components for heat dissipation.Connect the 24VDC power supply to the“+24V”and“GND”terminals—double-check polarity to avoid damage.Wire sensors to AI/DI terminals and actuators to AO/DO terminals,using the removable screw terminals for easy installation.Connect the RS485 communication cable to the designated port(A/B terminals).Power on the module and verify LED indicators:a steady green power light and blinking communication light(when connected to a PLC)confirm proper initial operation.Use the ALTOM Config Tool to set I/O ranges and test signal transmission.

Maintenance recommendations:Perform monthly visual inspections of ALTOM MD2000 029.220424 to check for loose wiring or dust buildup—clean terminals with a dry brush if needed.Every 6 months,calibrate analog channels using a standard signal generator(e.g.,4mA/20mA for current inputs)to ensure accuracy;if deviations exceed±0.1%,adjust via the configuration software.Backup the module’s settings monthly to a secure file,preventing loss in case of hardware replacement.If a fault occurs(e.g.,a DO channel fails to activate),first test the connected actuator and wiring;if the issue persists,use the Config Tool to reset the module to factory settings before contacting ALTOM support.

Product Guarantee

ALTOM MD2000 029.220424 comes with a 12-month manufacturer’s warranty from ALTOM,covering defects in materials and workmanship under normal operating conditions.During the warranty period,ALTOM will repair or replace ALTOM MD2000 029.220424 free of charge if failures result from manufacturing issues—provided the module was installed,wired,and maintained in accordance with ALTOM’s technical guidelines(e.g.,correct power supply voltage,compliance with I/O current limits).

Beyond the warranty,ALTOM offers technical support for ALTOM MD2000 029.220424,including access to online resources(user manuals,configuration guides)and direct assistance from automation engineers via email or phone.Customers can enroll in ALTOM’s Spare Parts Program to ensure timely delivery of replacement modules,minimizing downtime for critical applications.Each ALTOM MD2000 029.220424 undergoes rigorous testing(including functional checks,EMC stress tests,and temperature cycling)before shipment,ensuring it meets industrial quality standards.This guarantee gives users confidence that ALTOM MD2000 029.220424 will deliver reliable,consistent performance for their small-scale automation needs.