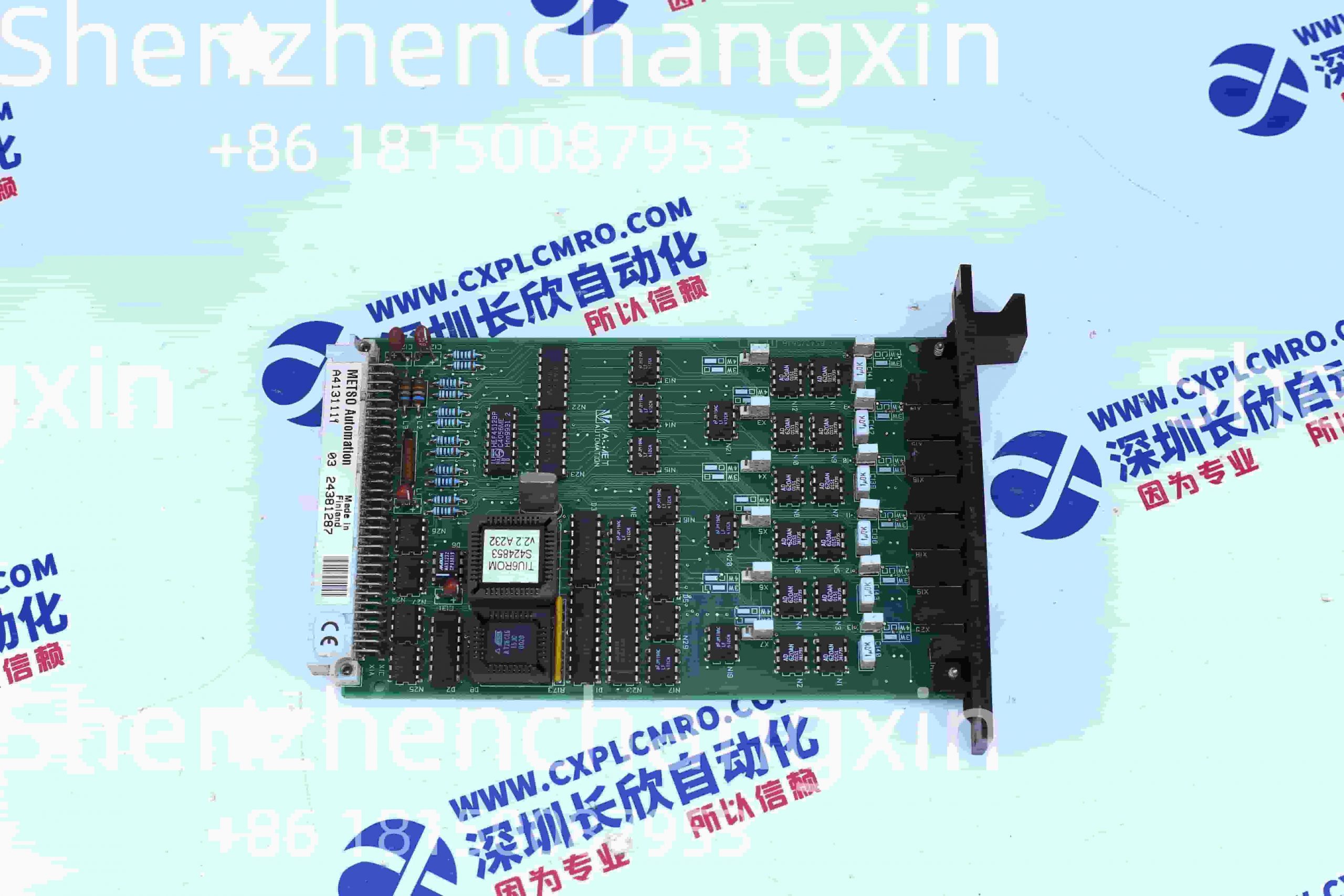

Product Description

TheMetso A413111is a high-precision NDIR(Non-Dispersive Infrared)gas detection module designed for continuous process gas analysis in industrial applications.This critical component serves as the sensing heart of analytical instrumentation,providing reliable measurement of specific gas concentrations in various process streams.Engineered for accuracy and stability,it ensures consistent performance in demanding industrial environments.

Measurement Principle:NDIR

Typical Gases:CO,CO₂,CH₄

Response Time:<10 seconds

Operating Pressure:0.5-5 bar

Technical Specifications

Parameter

Specification

Product Model

A413111

Manufacturer

Metso(Now part of Neles)

Product Type

NDIR Gas Detection Module

Measurement Principle

Non-Dispersive Infrared

Detection Method

Dual wavelength infrared absorption

Typical Measurement Gases

CO,CO₂,CH₄,SO₂

Measurement Range

Gas-specific(e.g.,0-100 ppm to 0-100%)

Accuracy

±1%of full scale

Repeatability

±0.5%of full scale

Response Time

T90<10 seconds

Operating Temperature

-10°C to+50°C

Sample Gas Temperature

Max.200°C

Operating Pressure

0.5 to 5 bar

Sample Flow Rate

0.5-2.0 L/min

Electrical Connection

Industry-standard connector

Calibration Interval

6-12 months recommended

Application Scenarios

In a chemical plant’s ethylene production process,theMetso A413111NDIR modules were deployed to monitor CO concentrations in reactor off-gases.The modules demonstrated exceptional stability by maintaining measurement accuracy despite fluctuating process conditions,enabling precise control of catalyst efficiency and preventing yield losses estimated at$50,000 per hour of suboptimal operation.

Technical Principles and Innovative Values

Innovation Point 1:Advanced Optical Design-TheA413111utilizes a stable dual-wavelength infrared detection system with temperature-compensated detectors,minimizing drift and ensuring long-term measurement accuracy without frequent recalibration.

Innovation Point 2:Robust Gas Cell Construction-Featuring corrosion-resistant materials and optimized optical path length,the module maintains integrity when analyzing aggressive process gases,extending service life in harsh applications.

Innovation Point 3:Intelligent Signal Processing-Integrated temperature and pressure compensation algorithms automatically correct for environmental variations,delivering reliable concentration readings under changing process conditions.

Application Cases and Industry Value

A power plant implementedMetso A413111modules in their flue gas analysis systems to optimize combustion efficiency.The precise CO and CO₂measurements enabled air-fuel ratio adjustments that improved boiler efficiency by 2%,resulting in annual fuel savings exceeding$200,000 while reducing NOx emissions by 15%.

Related Product Combination Solutions

Metso Sampling System Components-Sample conditioning equipment

Metso Calibration Gas Kits-Reference gases for calibration

Metso Analyzer Enclosures-Protective housings for analyzers

Metso Sensor Electronics-Signal processing modules

Metso Communication Interfaces-Data transmission components

Installation and Maintenance

Installation Preparation:Ensure proper sample conditioning and verify gas compatibility before installation.Follow strict cleanliness procedures to prevent optical path contamination.

Maintenance Protocol:Perform quarterly accuracy checks and annual full calibrations.Replace optical window seals as needed and maintain calibration gas certifications.

Product Assurance

Metso provides comprehensive technical support for theA413111module.Our global service network offers application assistance and calibration services.

Contact us for application-specific guidance and technical support for your process gas analysis requirements.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!