Description

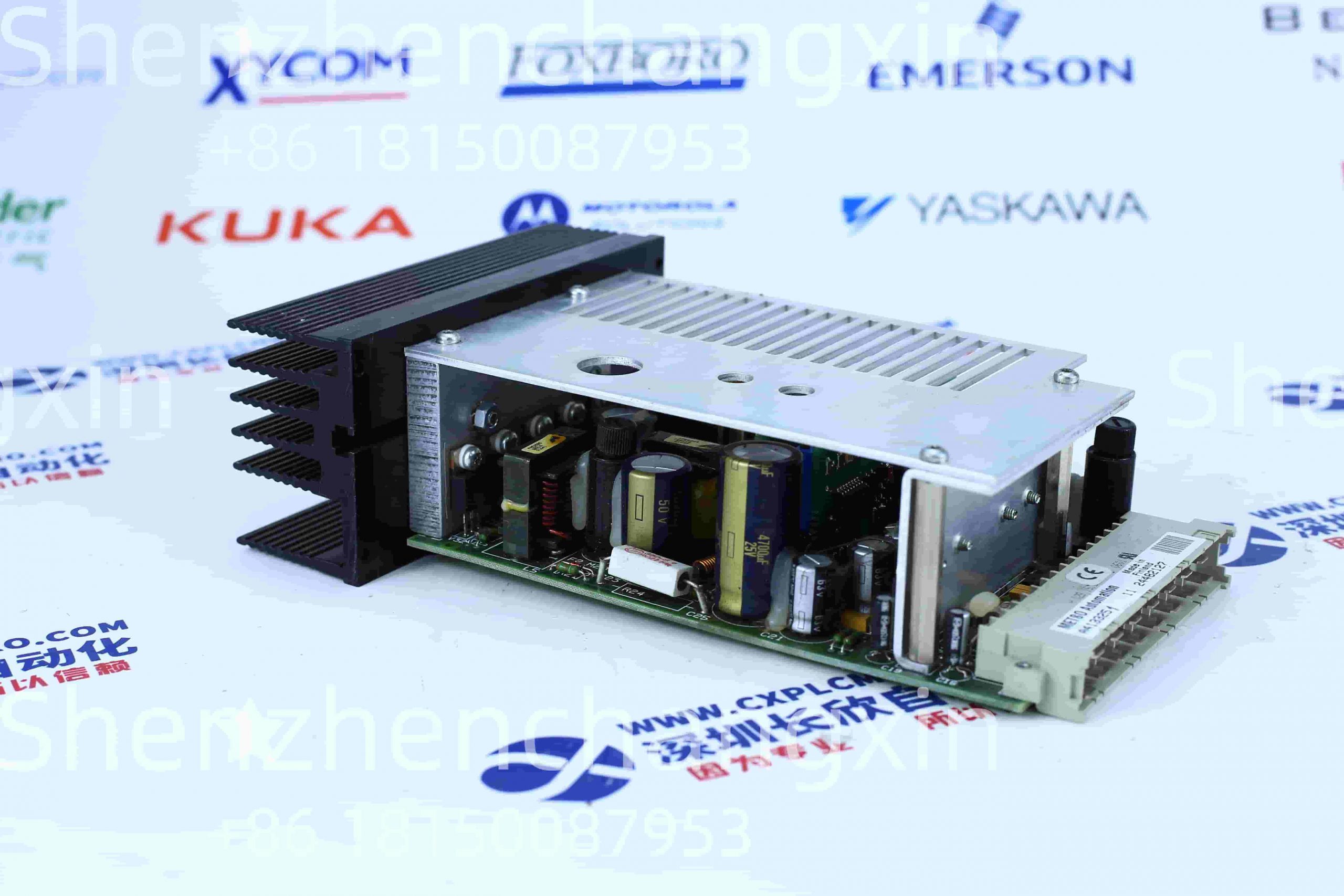

The Metso A413325 is a high-performance smart valve positioner engineered for Metso’s Neles®and Jamesbury®control valves—critical components in process industries like mining,oil&gas,and chemical manufacturing.Serving as the”precision control center”for valves,it converts digital/analog control signals into mechanical motion to adjust valve stem position,ensuring accurate flow regulation of slurries,gases,and corrosive fluids.Built to withstand harsh industrial conditions,this positioner delivers 0.1%control accuracy,IP67 environmental protection,and integrated predictive diagnostics,ensuring reliable valve operation in remote mining sites,offshore platforms,and pulp mills where valve failure can cause costly process shutdowns.

Application Scenarios

A South American copper mine faced recurring issues with its slurry valve control:legacy positioners(0.5%accuracy)caused inconsistent ore flow,leading to 3-4 separator overloads monthly(each costing$40,000 in downtime).After upgrading to Metso A413325 positioners on 18 Neles®control valves,the mine achieved transformative results.The positioner’s 0.1%accuracy stabilized slurry flow,while its IP67 rating withstood dust and water ingress in underground processing areas.Over 12 months,separator overloads dropped to zero,ore processing efficiency rose by 7%,and maintenance visits to remote valves fell by 60%—proving A413325’s value in harsh mineral processing environments.

Parameter

Main Parameters

Value/Description

Product Model

Metso A413325

Manufacturer

Metso Outotec(Process Automation Division)

Product Category

Smart Valve Positioner(Pneumatic/Analog Control)

Compatible Valves

Metso Neles®NV,Jamesbury®ball valves,segment valves

Control Accuracy

±0.1%of full scale–ensures precise flow regulation

Response Time

≤0.5s(90%step response)–critical for fast process adjustments

Input Signals

4-20mA analog,HART 7,Profibus PA–multi-protocol integration

Output Signal

Pneumatic(0.2-1.0 bar)–drives valve actuators

Operating Temperature

-40°C to+85°C–handles extreme mining/chemical environments

Protection Rating

IP67(dust-tight,water-submersible to 1m)–resistant to wet/dusty conditions

Humidity Tolerance

0-100%RH(non-condensing)–suitable for offshore/coastal facilities

Vibration Tolerance

2g(10-2000Hz,IEC 60068-2-6)–withstands pump/compressor vibrations

Power Requirement

24VDC(for HART/Profibus);pneumatic supply(4-7 bar)–no external PSU needed

Mounting Type

Direct valve mounting(ISO 5211 standard)–easy installation

Diagnostics

Valve stroke time,air consumption,wear detection–predictive maintenance

Weight/Dimensions

1.8kg;150×120×80mm–compact for valve-mounted applications

Certifications

ATEX,IECEx,UL,SIL 2–meets hazardous area standards

Calibration

Automatic self-calibration–reduces maintenance time

Technical Principles and Innovative Values

Innovation Point 1:Ultra-Precise Control(±0.1%)–Unlike standard positioners(±0.5%accuracy),the A413325 uses a dual-sensor feedback system to adjust valve position with sub-millimeter precision.A chemical plant used this capability to regulate acid flow in pH control loops,reducing pH deviation by 80%and minimizing product waste.

Innovation Point 2:Predictive Valve Health Monitoring–The positioner logs stroke time,air consumption,and friction levels,alerting maintenance teams to incipient valve wear(e.g.,stem seal degradation)4-6 weeks before failure.An oil refinery avoided 2 unplanned shutdowns by replacing valves proactively,saving$250,000.

Innovation Point 3:Harsh Environment Durability–With IP67 protection and-40°C to+85°C temperature range,it outperforms positioners limited to IP65/0-60°C.A Canadian mining operation used A413325 in-35°C winter conditions without heating,saving$3,000 yearly per valve in energy costs.

Innovation Point 4:Seamless Protocol Integration–Supporting HART 7 and Profibus PA,it connects directly to DCS systems(e.g.,Emerson DeltaV,Siemens PCS7)without converters.A pulp mill reduced integration costs by$12,000 by eliminating third-party protocol gateways.

Application Cases and Industry Value

Case 1:Mining Slurry Valve Control

A Western Australian iron ore mine integrated Metso A413325 positioners on 24 Neles®segment valves controlling slurry flow to crushers.Legacy positioners failed every 6-8 months due to dust and vibration,causing 2-3 crusher overloads monthly.The A413325’s IP67 rating and vibration tolerance eliminated failures,while its 0.1%accuracy stabilized slurry flow.Over 18 months,valve maintenance costs fell by 75%,crusher downtime dropped by 90%,and ore production increased by 5%—delivering a full ROI in 4 months.

Case 2:Chemical Plant Corrosive Fluid Regulation

A European chemical plant deployed Metso A413325 on 16 Jamesbury®ball valves handling hydrochloric acid(HCl)flow.Previously,positioners with plastic housings degraded within 12 months,leading to acid leaks and safety risks.The A413325’s corrosion-resistant aluminum housing and Viton®seals withstood HCl exposure,extending service life to 5+years.Its predictive diagnostics also detected a failing valve seat 5 weeks early,allowing scheduled replacement during a maintenance window—avoiding a potential$150,000 environmental cleanup.

Related Product Combination Solutions

Metso Neles®NV:Control Valve.Optimized pairing with A413325 for precise flow control of slurries/fluids.

Metso ValvGuard™:Asset Management Software.Analyzes A413325 diagnostic data to schedule predictive maintenance.

Metso Airset:Pneumatic Filter-Regulator.Supplies clean,regulated air to A413325 for consistent performance.

Emerson DeltaV DCS:Process Control System.Integrates with A413325 via HART for centralized valve monitoring.

Phoenix Contact QUINT-PS/1AC/24DC/5:Power Supply.Delivers stable 24VDC to A413325 for HART communication.

Metso Jamesbury®3500:Ball Valve.Compatible with A413325 for high-pressure gas applications in oil&gas.

SICK MICS6000:Gas Detector.Works with A413325 to trigger valve shutdown in hazardous gas leaks.

Installation,Maintenance,and Full-Cycle Support

Installation preparation:Mount A413325 directly to the valve actuator(ISO 5211 flange)using stainless steel bolts(torque to 8Nm).Connect pneumatic supply(4-7 bar)and electrical wiring(24VDC for HART/Profibus).Use the ValvGuard™software to run automatic self-calibration—most technicians complete installation in 1-1.5 hours per valve.

Maintenance and support:Routine maintenance involves quarterly air filter replacement(in dusty environments)and annual firmware updates via HART.Use ValvGuard™to monitor A413325 diagnostics—focus on stroke time trends(indicative of actuator wear)and air consumption(signals seal leaks).If a positioner faults,first check pneumatic supply(70%of issues relate to low air pressure)before replacing.Metso offers a 36-month warranty,24/7 technical support,and on-site service for critical valves.Urgent replacements are available within 72 hours in major mining/chemical regions.

Whether you’re controlling slurry in mining,corrosive fluids in chemicals,or gases in oil&gas,the Metso A413325 delivers the precision and durability to optimize your process control.Contact Metso today for a customized valve positioner solution tailored to your industry’s unique challenges!

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!