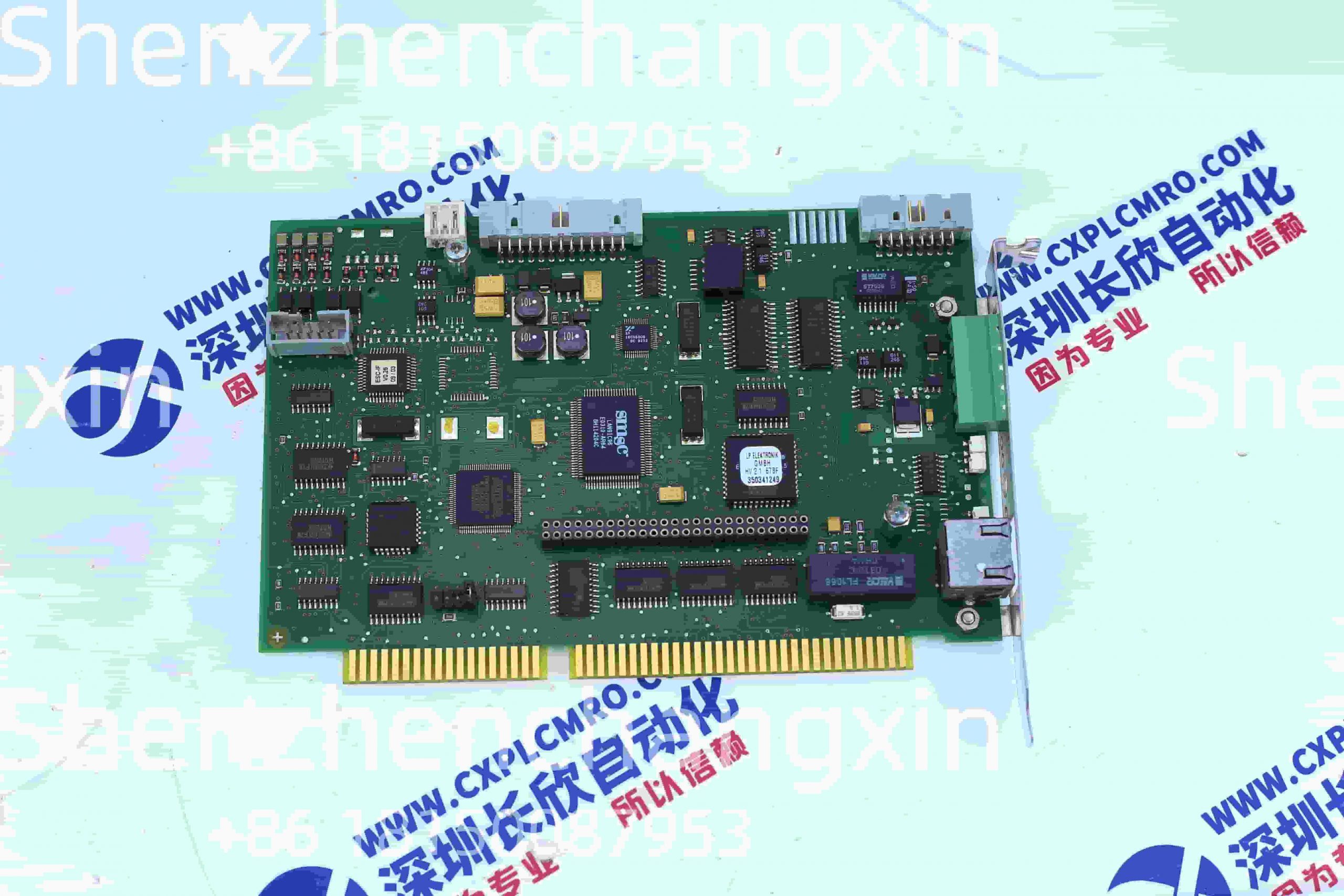

Description

The KUKA MFC2(Motion Fieldbus Controller 2)is a high-performance control module serving as the”motion brain”for KUKA’s KR series industrial robots,including KR QUANTEC,KR FORTEC,and collaborative LBR iisy models.It processes motion commands,executes complex trajectories,and synchronizes robot axes with external equipment(e.g.,conveyors,grippers,and welding torches)in real time.Engineered for the demanding requirements of industrial automation,this module delivers 1ms position update rates,multi-axis interpolation,and integrated safety functions(SIL 3),ensuring precise,reliable operation in automotive manufacturing,electronics assembly,and heavy industry applications where sub-millimeter accuracy and system uptime are critical.

Application Scenarios

A European automotive OEM faced challenges with its door panel welding robots:legacy controllers with 5ms update rates caused trajectory deviations(±0.3mm)during high-speed welding,leading to 3-4%of panels requiring rework.After upgrading to KUKA MFC2 modules,the manufacturer achieved transformative results.The module’s 1ms update rate reduced positioning errors to±0.05mm,while its advanced path planning minimized vibration during corner welds.Over 12 months,rework costs dropped by 92%,welding cycle time decreased by 8%,and overall equipment effectiveness(OEE)improved from 82%to 94%—proving MFC2’s value in high-precision robotic applications.

Parameter

|Main Parameters|Value/Description||—————–|——————-||Product Model|KUKA MFC2||Manufacturer|KUKA AG(Robotics Division)||Product Category|Motion Control Module for Industrial Robots||Compatible Robot Series|KR QUANTEC,KR FORTEC,LBR iisy,KR CYBERTECH||Update Rate|1ms–ensures precise motion control at high speeds||Axis Control Capacity|Up to 12 axes–supports multi-robot cells and external axes||Positioning Accuracy|±0.02mm(repeatability)–critical for精密装配tasks||Communication Interfaces|PROFINET,EtherCAT,Ethernet/IP–seamless factory integration||Safety Functions|SIL 3,PL e–integrated safety stops and collision detection||Processing Power|1.8GHz dual-core processor–handles complex motion algorithms||Operating Temperature|0°C to+45°C–suitable for factory floor environments||Storage Temperature|-20°C to+60°C–safe for warehouse storage||Power Requirement|24VDC±10%(5A max)–supplied by robot control cabinet||Mounting Location|Integrated into KUKA KRC4/KRC5 control cabinets||Vibration Resistance|5g(10-500Hz)–withstands robot operation vibrations||Protection Rating|IP20(control cabinet mounted)–protected from dust/water||Certifications|CE,UL,ISO 13849-1–meets global safety standards||Weight/Dimensions|1.2kg;150×100×50mm–compact design for control cabinets||Software Compatibility|KUKA.WorkVisual 6.0+–for programming and configuration|

Technical Principles and Innovative Values

Innovation Point 1:Ultra-Fast 1ms Update Rate–Unlike legacy controllers(5-10ms),the MFC2 updates robot positions every millisecond,enabling smooth motion at speeds up to 8m/s while maintaining±0.02mm accuracy.An electronics manufacturer used this capability to achieve 0.1mm precision in circuit board handling,reducing component damage by 90%.

Innovation Point 2:Advanced Path Interpolation–The module uses 7th-order polynomial interpolation to eliminate jerk during trajectory changes,reducing cycle times by 5-10%in pick-and-place applications.A logistics provider increased parcel sorting throughput by 12%after upgrading to MFC2-equipped robots.

Innovation Point 3:Multi-Axis Synchronization–With capacity for 12 axes,MFC2 precisely coordinates robot arms with external linear tracks and rotary tables(synchronization error<0.5ms).An aerospace supplier used this feature to automate wing component drilling,reducing setup time by 40%.

Innovation Point 4:Integrated Safety Architecture–The module’s SIL 3 safety functions eliminate the need for external safety controllers,reducing cabinet space by 30%and simplifying compliance with ISO 10218.A food packaging plant reduced safety system costs by$15,000 per robot cell.

Application Cases and Industry Value

Case 1:Automotive Body-in-White Welding

A U.S.automotive plant integrated KUKA MFC2 modules into 24 KR QUANTEC welding robots for body-in-white production.Previously,positioning errors caused inconsistent weld bead formation,requiring 20%of welds to be reworked.The MFC2’s 1ms update rate and advanced motion control reduced errors to<1%,while its PROFINET interface synchronized welding guns with robot motion.Over 18 months,rework costs fell by$850,000,and production output increased by 15%due to faster cycle times.

Case 2:Electronics Precision Assembly

A Southeast Asian electronics manufacturer deployed KUKA MFC2-equipped LBR iisy collaborative robots for smartphone camera module assembly.The module’s±0.02mm repeatability enabled precise placement of 0.3mm components,while its collision detection(powered by MFC2’s real-time processing)ensured safe human-robot collaboration.Compared to manual assembly,defect rates dropped from 8%to 0.5%,and production capacity increased by 30%—justifying the investment in 6 months.

Related Product Combination Solutions

KUKA KRC5:Robot Controller Cabinet.Houses the MFC2 module and provides power/distribution for KR series robots.

KUKA.WorkVisual:Programming Software.Configures MFC2 parameters,designs motion trajectories,and monitors performance.

KUKA SafeOperation:Safety Software.Extends MFC2’s safety functions with customizable safety zones and collaborative modes.

Phoenix Contact PROFINET Switch:Network Component.Enables reliable communication between MFC2 and factory MES systems.

Festo DGST:Gripper System.Integrates with MFC2 via EtherCAT for synchronized material handling.

KUKA CCU:Cell Control Unit.Coordinates multiple MFC2-equipped robots in complex production cells.

SICK S3000:Safety Laser Scanner.Works with MFC2 to create protective fields around robot workspaces.

Installation,Maintenance,and Full-Cycle Support

Installation preparation:The MFC2 module is factory-installed in KUKA KRC4/KRC5 control cabinets,but field replacement requires certified technicians.Power off the control cabinet,disconnect the 24VDC supply,and replace the module using anti-static procedures.Reconfigure parameters via KUKA.WorkVisual software,ensuring compatibility with robot model and application requirements.Typical replacement time:1-2 hours.

Maintenance and support:Routine maintenance involves monthly visual inspections(check for connector corrosion)and quarterly software updates via KUKA.WorkVisual.Monitor MFC2 status via the robot teach pendant—alarms for overheating or communication errors trigger immediate notifications.Most issues are resolved through parameter adjustment(60%)or connector cleaning(30%).KUKA offers a 36-month warranty,24/7 technical support,and on-site service for critical production lines.Urgent replacements are available within 48 hours in major industrial regions.

Whether you’re automating welding lines in automotive,precision assembly in electronics,or material handling in logistics,the KUKA MFC2 delivers the speed and accuracy to maximize your robotic system’s performance.Contact KUKA for a customized upgrade or integration plan tailored to your production needs!

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!