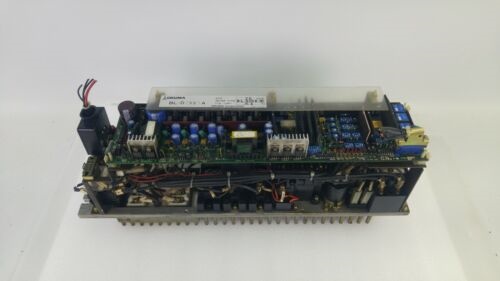

Description:

The Okuma BLII-D75A Servo Drive is a high-performance,single-axis AC servo amplifier manufactured by OKUMA,a world leader in CNC machine tools.This drive is a critical component in the machine’s motion control system,designed to convert control signals from the CNC controller into precise power delivery for a single servo motor.With its 75A continuous current capacity,the BLII-D75A is engineered to provide dynamic response,high accuracy,and robust motion control for demanding machine axes,ensuring exceptional performance and reliability in rigorous industrial applications.

Application Scenarios:

Imagine a large metal fabrication facility operating an OKUMA CNC laser cutting machine,which requires extremely fast and precise linear movements along its primary cutting axis(e.g.,the X-axis)to maintain high throughput and cut quality.The sheer speed and accuracy needed for continuous profiling of thick steel plates demand a powerful and responsive servo drive.If the existing drive for this axis begins to exhibit erratic behavior or insufficient current delivery,it can lead to inaccurate cuts,wasted material,and significant production bottlenecks.The Okuma BLII-D75A Servo Drive,with its robust 75A continuous current output,is perfectly suited for such high-dynamic and high-power single-axis applications.It ensures that the cutting head maintains its commanded velocity and position with unwavering precision,even during rapid accelerations and decelerations.A functional Okuma BLII-D75A Servo Drive directly addresses the pain points of compromised cut quality,lost production time,and the critical need for uncompromising power and precision in high-stakes manufacturing operations.

Parameter:

Main Parameters

Value/Description

Product Model

BLII-D75A

Manufacturer

OKUMA

Product Category

Single-Axis AC Servo Drive/Servo Amplifier

Axis Specification

Single-Axis Drive–Controls one independent servo motor for a specific machine axis.

Continuous Current

75 A(Amperes)–Provides robust sustained current output for demanding axis operations.

Peak Current

150 A(Typical)–Offers significant peak current for rapid acceleration and dynamic loads.

AC Input Voltage

200V Class(e.g.,180-220V AC)–Typical voltage range for industrial power supplies.

DC Bus Voltage

150 V(Volts)–Common internal DC link voltage for power conversion within the drive.

Compatible Motors

OKUMA BL-Series Servo Motors–Optimized for seamless integration with Okuma’s brushless AC servo motors.

Control System

OSP-5020M/L,OSP-7000M/L Compatible–Designed for integration with specific Okuma CNC systems.

Key Features

Integrated Power Supply&Control Board(Type A)–Self-contained design simplifies installation and maintenance.

Connection Ports

Motor output(U,V,W),Feedback,Brake Resistor,Temperature Sensor,Holding Brake–Standard industrial interfaces.

Weight(Approx.)

5 kg/11 lbs–Indicates a robust yet manageable construction for its power rating.

Installation

Cabinet Mounted–Designed for secure installation within the machine’s electrical control cabinet.

Technical Principles and Innovative Values:

The Okuma BLII-D75A Servo Drive is engineered with advanced power electronics and digital control algorithms,making it a cornerstone for high-performance single-axis motion control in Okuma CNC machines.

Innovation Point 1:High-Power Density and Precise Current Control:The BLII-D75A is designed to deliver a substantial 75A of continuous current in a relatively compact form factor,achieving high power density.It utilizes a sophisticated digital current loop control,driven by high-speed Digital Signal Processors(DSPs),which ensures extremely accurate and responsive control over the motor’s torque.This precision is critical for maintaining stable cutting conditions,achieving tight tolerances,and providing smooth,vibration-free motion even during high-force machining operations,directly translating to superior part quality and extended tool life.

Innovation Point 2:Robust Protection and Enhanced Reliability:Built for the demanding conditions of industrial environments,the BLII-D75A incorporates a comprehensive suite of integrated protection mechanisms.These include real-time monitoring for conditions such as overcurrent(both motor and servo side),overvoltage,undervoltage,and thermal overloads.In the event of a detected fault,the drive rapidly activates protective shutdowns,safeguarding both its internal components and the connected high-value servo motor from damage.This inherent robustness and self-protective capability significantly enhance the overall reliability,uptime,and operational safety of the CNC machine.

Innovation Point 3:Seamless Integration with OKUMA OSP Systems:As a core component of the BLII series,the BLII-D75A is specifically engineered for native compatibility with OKUMA’s proprietary OSP(Okuma Sampling Path)CNC control systems,particularly the OSP-5020M/L and OSP-7000M/L series.This deep integration ensures optimal communication,simplified commissioning procedures,and reliable data exchange for real-time control,diagnostics,and alarm reporting.Its design as a direct replacement or upgrade unit within the OKUMA ecosystem streamlines maintenance and minimizes compatibility issues,extending the operational life of existing machinery.

Application Cases and Industry Value:

In a demanding aerospace parts manufacturing facility,an OKUMA vertical machining center was experiencing intermittent slowdowns and positional inaccuracies on its main Z-axis during heavy-duty material removal.Diagnostics revealed a weakness in the existing servo drive.Replacing it with a high-performance Okuma BLII-D75A Servo Drive immediately restored the Z-axis’s full dynamic capability.The drive’s ability to maintain a consistent 75A current output under heavy cutting loads ensured stable feed rates and eliminated chatter,resulting in a 10%reduction in cycle time per part and a significant improvement in surface finish.This directly led to increased production throughput and a reduction in post-machining operations,highlighting the drive’s crucial role in optimizing high-value manufacturing processes.

Another example is a specialized fabrication shop that uses an OKUMA plasma cutting system for intricate designs on large metal sheets.The Y-axis,responsible for the long traverse,required both high speed and considerable power for dynamic movements.When the original drive failed,causing machine downtime,the immediate availability and robust capabilities of the Okuma BLII-D75A Servo Drive proved invaluable.Its 75A output capacity enabled the Y-axis to execute rapid,long-distance moves with precise acceleration and deceleration profiles,ensuring perfectly formed cuts across large workpieces.This quick and effective replacement maintained production schedules and prevented costly delays,demonstrating the drive’s contribution to efficiency and product quality in a high-speed production environment.

Related Product Combination Solutions:

The Okuma BLII-D75A Servo Drive is an essential component within a broader OKUMA CNC motion control system and typically functions in conjunction with:

OKUMA BL-Series Servo Motors(e.g.,high-power BL-MH or BL-MC series motors):These are the brushless AC servo motors that the BLII-D75A powers and precisely controls.

OKUMA OSP-5020M/L CNC Controllers:Main CNC control units that interface directly with the BLII-D75A for motion command execution.

OKUMA OSP-7000M/L CNC Controllers:Newer generation CNC control units also compatible with and utilizing this drive for advanced control.

OKUMA Feedback Devices(e.g.,ER-FC Series Encoders,ER-J Series Encoders):High-resolution encoders mounted on the servo motors that provide real-time positional and velocity feedback to the BLII-D75A.

OKUMA BLIV-D Series Servo Drives(e.g.,BLIV-D100A,configurable):Modern BLIV series drives may serve as maintenance or upgrade replacements,as they often offer backward compatibility and configurable current outputs(e.g.,a 100A BLIV-D can often be set to a 75A equivalent).

OKUMA Power Supply Units(PSU)for Drives:These units provide the main DC bus power to the drive system,typically feeding into the BLII-D75A.

OKUMA Cables(Power and Feedback):Specific shielded cables designed for reliable connection between the BLII-D75A and the motor,and the CNC controller,ensuring signal integrity in an industrial environment.

Installation,Maintenance,and Full-Cycle Support:

The installation of the Okuma BLII-D75A Servo Drive demands precise attention to both electrical and mechanical procedures to ensure optimal functionality,accuracy,and operator safety.Prior to any installation or replacement,it is absolutely paramount to completely disconnect and lock out all power sources to the CNC machine and the servo drive system.Ample time must be allowed for the internal DC bus capacitors to fully discharge,typically indicated by the extinguishing of a DC Charge LED.The drive should be securely mounted within the electrical control cabinet,ensuring adequate ventilation and airflow to prevent overheating.All electrical connections—including AC input power,motor output phases(U,V,W),and control/feedback signals—must strictly adhere to OKUMA’s detailed wiring diagrams and local electrical codes to prevent damage to the drive,motor,or the main controller.Post-physical installation,a thorough commissioning process is essential,involving verification of wiring,configuration of any specific drive parameters(if applicable via jumpers or software settings),and confirming accurate communication and feedback with the CNC controller.This often requires specialized OKUMA diagnostic software for precise calibration and tuning.

Routine maintenance for the Okuma BLII-D75A Servo Drive primarily involves maintaining a clean and dry internal environment within the electrical cabinet.This prevents the accumulation of dust,metal particles,and moisture,which can degrade components or cause short circuits.Periodically inspect the drive for any visible signs of overheating,such as discolored components or bulging capacitors,and ensure that any cooling fans(if present)are operating freely and not obstructed.All terminal connections should be checked for tightness,and external cables should be inspected for any signs of wear,fraying,or damage,particularly in high-flex areas.Consistent power quality and appropriate environmental conditions are crucial for the longevity of the BLII-D75A.In the event of a fault,the drive’s built-in LED indicators and system alarms provide crucial diagnostic information.Our dedicated technical support team offers comprehensive assistance,from initial installation guidance and performance optimization to expert troubleshooting and sourcing of genuine replacement parts,ensuring your Okuma BLII-D75A Servo Drive continues to deliver reliable and precise motion control throughout its extensive operational life.

Choose Shenzhen Changxin for worry-free after-sales service and high-quality products. We only cooperate with first-tier brand manufacturers in the industry. Our products are imported and comprehensive. We provide thoughtful pre-sales service, communicating multiple times with customers about product models, quality, prices, and delivery schedules to jointly confirm the solutions and address users’ concerns in advance. Business execution is in place, ensuring on-time delivery of ordered products and formulating a comprehensive delivery plan to guarantee the project schedule. We also assist users in handling acceptance procedures. Our after-sales service is impeccable. For any problems during the warranty period, we only replace, not repair. We never shirk responsibilities or pass the buck when encountering problems. Our service hotline is available 24/7: 18150087953 SOLEMN COMMITMENT 1. For all items, modules, and cards sold by our company, if any quality problems occur during normal use within the warranty period, we will provide free replacements without any excuse or delay. 2. For non-discontinued materials and equipment that are out of the warranty period, we only charge the cost of relevant accessories for quality problems. 3. For discontinued materials and equipment, we provide alternative models and equipment replacement process services. 4. For the materials and equipment purchased by customers, we offer lifetime free system software upgrades and provide relevant technical documents for free. 5. We regularly follow up on the usage of the materials purchased by customers and promptly solve any problems. 6. Our company’s hotline provides 24-hour service, and we will respond to customers’ questions within 1 hour. 7. For any other matters not covered, our company adheres to the attitude of “thoughtful service and full responsibility” and solves problems from the customer’s perspective in a practical way. With a serious and rigorous corporate style, we wholeheartedly serve every customer. The company mainly imports PLC modules, programmable controllers, servo control systems and DCS spare parts, such as: ABB, AB (Rockwell), GE (General Electric), Bentley, Honeywell, Emerson, Motorola, Invensys, Westinghouse, etc. The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers, and can directly purchase from abroad, providing equipment and spare parts from different countries and manufacturers. We supply directly from abroad, without middlemen, reducing the cost of use. There is really no middleman who can make a price difference! ! If you have any defects or need to import PLC, DCS spare parts, please contact our team, we will help you find reliable and high-quality products super quickly, while shortening the delivery time to ensure that your equipment can operate normally in the right environment. On time. Professionally provide: PLC programmable control system, distributed control system (DCS), safety instrument system (SIS), ESD system, vibration monitoring system, turbine compressor control system (CCS) and other PLC modules, various industrial control systems, system modules, CPU, IO module, DO module, AI module, DI module, network communication module, Ethernet module, motion controller, analog input module, analog output module, switch input module, switch output module, module redundancy, power supply module, relay output unit, relay input unit, processing unit. Products are widely used in: electricity, petroleum, mine hoisting, ports, heating, gas, water supply, sewage treatment, metallurgy, papermaking, textile, chemical industry, water conservancy and other modern industrial fields! ABB 5SHY3545L0010/3BHB013088R0001 MOTOROLA MVME2434 MOTOROLA MVME2432 A-B 81001-450-53-R ABB PNI800 WOODWARD 9907-164 NI PXIE-4145 ABB CI871K01 3BSE056797R1 MOTOROLA MVME5500-0161 MOTOROLA MVME5500-0163 EMERSON MVME55006E-0163 GE DS200DCFBG1BJB ABB PPD113B01-10-150000 ABB PM904F 3BDH001002R0001 MOTOROLA MVME2400 FOXBORO H92A0K9V0H00 PIONEER MAGNETICS PM36218B-10P-1-8PH-J GE IC698CPE040-JP EMERSON MVME7100 ABB HPC800K02 ABB SYN5202-0277 ABB HPC800K02(含HC800模块、CP800模块、底座) MOTOROLA MVME5500 MOTOROLA MVME55006E-0163R GE IS215UCVEM09B AMAT 0090-76110 VME PCB ABB 5SHX2645L0002/3HB012961R0001 ABB AO2000-LS25 ABB PM865K01 3BSE031151R1 ABB 5SHX1445H0001 3BHL000391P0101 3BHB003230R0101 5SXE05-0152 KONGSBERG DPS112 GE VMIVME-7750 ABB AO2000-LS25 TRICON 4352B ABB PFSK152 TRICONEX 3009 MOOG D136-001-007 SCANde INTELLISCANDE14-405NM SCANLAB