Description

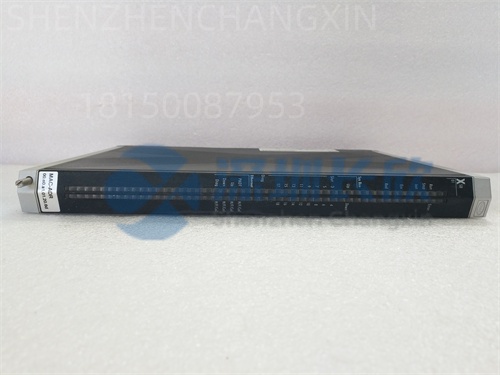

The HIMA X-SB01 (Part No. 985210207) is a critical hardware component in HIMA’s HIMax safety control system, serving as the I/O baseplate or carrier module that provides mechanical support, power distribution, and high-integrity signal backplane connectivity for plug-in I/O modules (e.g., F-DI, F-AI, F-DO) and controller units like the H51q or H41q CPUs.

Designed for use in Safety Instrumented Systems (SIS) up to SIL 3 (IEC 61508/61511), the X-SB01 enables secure, redundant communication between field devices and the safety logic solver. It features dual power inputs, galvanic isolation, and supports hot-swap capability—allowing module replacement without shutting down the entire safety system. The unit mounts on a standard 35 mm DIN rail inside certified safety cabinets and is commonly deployed in oil & gas, chemical processing, power generation, and railway signaling applications.

Application Scenarios

At a LNG export terminal in Australia, a fire & gas detection system based on HIMA HIMax required maximum uptime during tropical cyclone season, when humidity and salt corrosion threatened electronics. The engineering team specified the HIMA X-SB01 985210207 baseplates across all remote I/O shelters due to their conformal-coated PCB options and robust terminal design. During a Category 4 cyclone, while non-safety systems failed, the X-SB01-based SIS remained fully operational—maintaining emergency shutdown readiness. Maintenance crews later performed hot-swaps of a faulty F-DI16 digital input module without interrupting burner management logic, thanks to the X-SB01’s live-insertion architecture. In life-critical safety systems, the baseplate isn’t just infrastructure—it’s part of the defense-in-depth strategy.

Technical Principles and Innovative Values

Innovation Point 1: Integrated Redundancy at the Base Level – The X-SB01 supports dual power feeds and redundant data paths, ensuring that a single point of failure in cabling or supply doesn’t compromise safety integrity—core to HIMA’s 1oo2D or 2oo3 voting architectures.

Innovation Point 2: True Hot-Swap for Continuous Safety – Unlike conventional PLC bases, the X-SB01 allows technicians to replace failed I/O modules without powering down the safety controller, maintaining SIL 3 compliance during maintenance—a rare capability in functional safety systems.

Innovation Point 3: Electromagnetic Resilience – Designed to operate in electrically noisy plants (e.g., near VFDs or arc furnaces), the X-SB01 meets stringent EMC requirements (IEC 61000-6-2/4), preventing spurious trips from EMI.

Innovation Point 4: Lifecycle Transparency – Each X-SB01 includes a unique serial number traceable via HIMA’s Safety Suite software, enabling full audit trails for regulatory compliance (e.g., OSHA PSM, EPA RMP).

Application Cases and Industry Value

A European ethylene oxide plant upgraded its reactor emergency cooling system to a HIMA HIMax SIS using X-SB01 985210207 baseplates. During a runaway reaction simulation test, the system triggered within 85 ms—well below the 150 ms process safety time. The X-SB01’s low-latency backplane and stable power delivery were key to this performance. Over five years, the site achieved zero spurious trips and passed all TÜV audits with full documentation traceability.

In a high-speed rail signaling project in Asia, X-SB01 carriers were used in trackside safety interlock cabinets exposed to monsoon rains and temperature swings from -10°C to +55°C. The units operated flawlessly for over 40.000 hours, proving their suitability for mobile and fixed infrastructure alike.

Related Product Combination Solutions

HIMA H51q: Safety CPU – mounts directly onto X-SB01 baseplate

HIMA F-DI16 (984845001): 16-channel digital input module – plugs into X-SB01

HIMA F-DO16 (984845002): 16-channel digital output module – for valve/shutdown actuation

HIMA F-AIH (984845005): Analog input module – for pressure/temperature safety thresholds

HIMA X-CPU01: Alternative base for CPU-only configurations

HIMA Safety Suite: Engineering & diagnostics software – auto-detects X-SB01 topology

Phoenix Contact AXC F 2152: Competitor safety PLC base – but lacks HIMA’s SIL 3 hot-swap

HIMA X-PB01: Power backplane module – often used alongside X-SB01 in large racks

Installation, Maintenance, and Full-Cycle Support

Installation requires mounting the X-SB01 on a grounded DIN rail inside a certified safety cabinet, connecting dual 24 VDC supplies (with proper fusing), and plugging in I/O or CPU modules until they click into place. Always follow HIMA’s torque specs for terminal blocks and ensure cabinet IP rating matches the environment (e.g., IP66 for outdoor use).

Maintenance is simplified by hot-swap: if an I/O module fails, remove it while the system runs—the X-SB01 maintains backplane integrity. Use HIMA Safety Suite to verify module recognition post-replacement.

We supply only 100% genuine HIMA X-SB01 985210207 units, complete with original packaging, certificates, and traceability. Our team provides compatibility validation, obsolescence monitoring, and rapid exchange—even for legacy HIMax systems. With global logistics and deep expertise in functional safety, we ensure your SIS foundation remains uncompromised.