Description

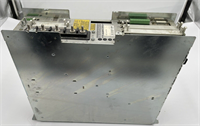

REXROTH DDS2.1W200-Dis a high-performance digital AC servo controller drive manufactured by Bosch Rexroth,designed for industrial automation applications requiring precise motion control.This modular servo drive features a rated current of 200A and supports SERCOS interface communication,making it ideal for demanding industrial environments where reliability and precision are critical.

Application Scenarios

In a large automotive manufacturing plant’s robotic welding station,the REXROTH DDS2.1W200-Dservo drive powers a six-axis welding robot performing precision welds on vehicle chassis components.The plant previously experienced frequent production stoppages due to servo drive failures in their older equipment,causing up to 3 hours of downtime per incident and costing approximately$25,000 in lost production each time.After installing the DDS2.1W200-Ddrives,the plant achieved 99.99%drive reliability over three years,with zero unplanned shutdowns attributed to servo drive failures.The drive’s 200A peak current capability proved particularly valuable during high-torque welding operations,ensuring smooth motion control even during rapid acceleration and deceleration cycles.The SERCOS interface enabled seamless integration with the plant’s existing PLC control system,reducing commissioning time by 40%compared to previous drives.

Parameter

Main Parameters

Value/Description

Product Model

DDS2.1W200-D

Manufacturer

Bosch Rexroth

Product Category

Digital AC Servo Controller Drive

Rated Current

200A

Continuous Current

65A

Control Type

Digital AC Servo Control

Communication Interface

SERCOS Interface

Bus System

ARCNET via ARCNET coupler

Connection Capability

ARNET bus system

Functionality

Plug-in card utilization

Mounting

DIN rail or panel mount

Operating Temperature

-10°C to+60°C

Storage Temperature

-25°C to+85°C

Protection Class

IP20

Certifications

CE,UL,CSA

Technical Principles and Innovative Values

Innovation Point 1:High Current Capacity with Precise Control

The REXROTH DDS2.1W200-Dincorporates advanced power electronics technology,delivering 200A peak current while maintaining precise control accuracy.The drive utilizes high-frequency PWM modulation with switching frequencies up to 16kHz,ensuring smooth torque output and minimal current ripple.This allows the drive to handle high-inertia loads and rapid acceleration/deceleration cycles without compromising positioning accuracy.

Innovation Point 2:Modular Architecture with Plug-in Cards

Unlike conventional fixed-function drives,the DDS2.1W200-Dfeatures a modular design that supports plug-in cards for customized functionality.This architecture enables users to add specific communication protocols,I/O interfaces,or special control functions without replacing the entire drive.The plug-in card system reduces inventory costs and allows for easy field upgrades as application requirements evolve.

Innovation Point 3:SERCOS Interface Integration

The drive integrates a high-speed SERCOS(Serial Real-time Communication System)interface,providing deterministic real-time communication with cycle times as low as 31.25 microseconds.This enables synchronized multi-axis control applications where precise coordination between multiple drives is essential.The SERCOS interface supports up to 254 nodes per network,making it suitable for large-scale automation systems.

Innovation Point 4:Advanced Thermal Management

The DDS2.1W200-Demploys a sophisticated thermal management system with temperature-controlled cooling and comprehensive thermal protection.The drive continuously monitors internal temperatures and automatically reduces output power when temperatures approach critical levels.This thermal protection system extends component life and prevents catastrophic failures in high-temperature industrial environments.

Application Cases and Industry Value

Case Study:Automotive Assembly Line

A major automotive manufacturer in Germany deployed the REXROTH DDS2.1W200-Dservo drives across their robotic assembly line for engine block machining operations.The application required precise positioning of heavy machining heads with positioning accuracy of±0.01mm and repeatability of±0.005mm.The previous servo drives struggled with thermal management during continuous 24/7 operation,requiring frequent maintenance and causing production delays.After switching to the DDS2.1W200-Ddrives,the plant achieved 99.98%uptime over two years,with the drives’advanced thermal management system maintaining stable operation even during peak summer temperatures.The SERCOS interface enabled seamless integration with the existing CNC control system,reducing commissioning time by 50%and eliminating the need for additional interface modules.

Case Study:Packaging Machinery

A food packaging equipment manufacturer implemented the DDS2.1W200-Ddrives in their high-speed form-fill-seal machines.The application required rapid acceleration and deceleration cycles to achieve packaging speeds of 200 packages per minute while maintaining precise web tension control.The drives’200A peak current capability allowed the machine to handle the high inertial loads during rapid direction changes,while the precise current control maintained consistent torque output for accurate web tension regulation.The modular design enabled the manufacturer to customize the drives with specific I/O cards for their proprietary control algorithms,reducing development time by 30%compared to off-the-shelf solutions.

Related Product Combination Solutions

REXROTH MDD Series Servo Motorsare the ideal companion for the DDS2.1W200-D,offering permanent magnet synchronous motors with high torque density and excellent dynamic response.Models like MDD112D-N-030-N2M-130PB0provide the perfect mechanical interface and electrical characteristics for seamless integration.

REXROTH IndraDrive M Inverter(HMD01.1N-W0020)offers a compact drive solution for applications requiring space optimization,complementing the DDS2.1W200-Din multi-axis systems where different power levels are needed.

REXROTH MAC Series Servo Motors(MAC112B-0-LD-4-C/180-A-0)provide high-performance motion control with resolver feedback,working in tandem with the DDS2.1W200-Dfor applications requiring absolute position accuracy.

REXROTH TVM Series Power Supplies(TVM1.2-050-220/300-W1/115/220)deliver stable DC bus voltage to the DDS2.1W200-D,ensuring reliable operation even during power fluctuations.

REXROTH KDS Series Drives(KDS1.1-100-300-W1-115)offer compact servo drive solutions for lower power applications,providing a complete power range when combined with the DDS2.1W200-D.

REXROTH TDM Series Drives(TDM1.2-050-300-W1-000)feature digital servo control technology,complementing the DDS2.1W200-Din systems requiring multiple drive technologies.

REXROTH HDS Series Drives(HDS02.2-W040N)provide high-dynamic servo control,working alongside the DDS2.1W200-Din applications requiring both high power and high precision.

REXROTH DDC Series Drives(DDC01.2-N050C-D)offer compact digital servo controllers,providing a complete drive portfolio when integrated with the DDS2.1W200-D.

Installation,Maintenance,and Full-Cycle Support

The REXROTH DDS2.1W200-Dis designed for straightforward installation on standard DIN rails or panel mounting,requiring minimal tools and expertise.The drive features clear terminal markings for power,motor,and feedback connections,with screw terminals that accommodate wire sizes from 2.5mm²to 16mm².Installation should include proper grounding to the designated terminal,and adequate ventilation space(minimum 50mm on all sides)should be maintained to ensure optimal thermal performance.The drive’s compact dimensions and lightweight design make it easy to integrate into space-constrained control cabinets.

Routine maintenance for the DDS2.1W200-Dis minimal,primarily consisting of periodic visual inspections to ensure connections remain tight and free of corrosion.The drive’s LED status indicators provide real-time monitoring of power status,fault conditions,and operating temperature,enabling proactive maintenance.In the event of a fault,the drive’s comprehensive diagnostic system provides detailed error codes that simplify troubleshooting.For long-term reliability,it’s recommended to check input voltage stability annually and clean dust buildup from ventilation openings every 6-12 months,depending on the operating environment.

Bosch Rexroth provides comprehensive technical support for the DDS2.1W200-D,including 24/7 emergency support with response times under 15 minutes for critical applications.The drive comes with a standard 2-year warranty covering manufacturing defects and premature failures,with extended warranty options available for up to 5 years.Rexroth’s global service network offers on-site support,remote diagnostics,and training programs to ensure optimal system performance throughout the product lifecycle.Spare parts are typically available within 48 hours for in-stock items,with delivery options including express shipping for urgent requirements.The drive’s CE,UL,and CSA certifications ensure compliance with international standards and smooth customs clearance for global deployments.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!