Description

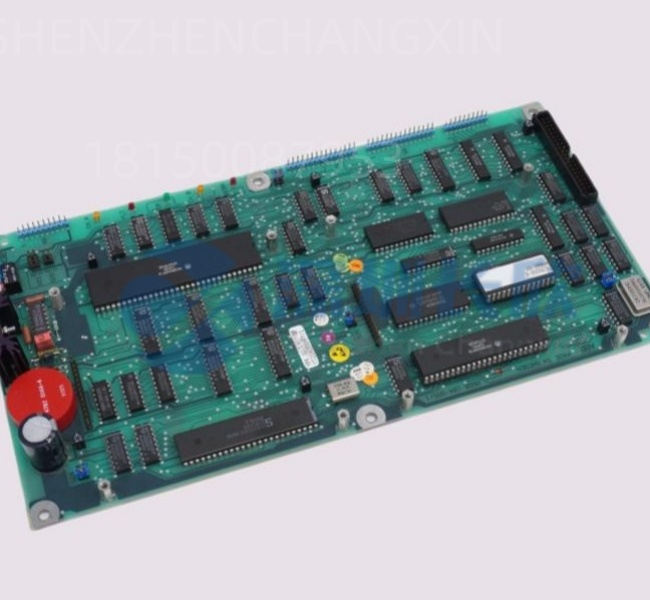

The REXROTH VT-HNC100-1-22/W-08-0-0 is a high-performance analog motion control card from Bosch Rexroth’s VT-HNC100 series,designed for precise closed-loop control of hydraulic cylinders and proportional/servo valves.It integrates command processing,feedback evaluation,and real-time current output to drive electro-hydraulic actuators with exceptional dynamic response and positioning accuracy.

As a key enabler of force,position,and velocity control in demanding industrial hydraulics,the REXROTH VT-HNC100-1-22/W-08-0-0 bridges the gap between traditional PLC logic and high-dynamic fluid power systems—delivering deterministic motion without requiring a full CNC or motion CPU.

Application Scenarios

At an automotive crash test facility in Germany,inconsistent sled acceleration profiles compromised data repeatability across impact simulations.Engineers replaced legacy relay-based valve controls with REXROTH VT-HNC100-1-22/W-08-0-0 modules driving 4WRPEH proportional valves on dual hydraulic rams.The card’s built-in PID regulator,combined with LVDT feedback,achieved±0.5 mm positioning accuracy at 1 m/s speeds and enabled programmable ramp profiles via±10 V setpoints from the central PLC.Over 500 test cycles,trajectory deviation dropped by 85%.In this environment,the REXROTH VT-HNC100-1-22/W-08-0-0 didn’t just move metal—it ensured scientific-grade reproducibility in life-critical safety validation.

Parameter

Main Parameters Value/Description

Product Model REXROTH VT-HNC100-1-22/W-08-0-0

Manufacturer Bosch Rexroth AG

Product Category Analog Hydraulic Axis Motion Control Module

Control Type Closed-loop position/velocity control with PID regulation

Command Input±10 V differential(analog setpoint)

Feedback Input±10 V(for LVDT,magnetostrictive,or potentiometer sensors)

Valve Output±10 V or±20 mA(configurable),4-quadrant capable

Control Loops Cascaded position+velocity loop with adjustable gains

Adjustment Method Potentiometers for P,I,D,ramp,and deadband(front-accessible)

Mounting Type DIN rail(TS35)or panel mount;plug-in terminal blocks

Operating Voltage 24 VDC(±10%),max 2 A

Environmental Rating IP20,operating temp:0°C to+50°C

Certifications CE,UL 508,EN 61000-6-2/4(industrial EMC)

Technical Principles and Innovative Values

Innovation Point 1:True Analog Determinism

Unlike digital-over-analog hybrids,the REXROTH VT-HNC100-1-22/W-08-0-0 processes control loops entirely in the analog domain—eliminating sampling delays and jitter.This enables sub-millisecond response critical for hydraulic instability suppression(e.g.,avoiding“hunting”in high-gain cylinder systems).

Innovation Point 2:Field-Tunable Without Software

All PID parameters,ramps,and offsets are adjusted via precision potentiometers on the front panel—allowing commissioning engineers to optimize performance on-site using only an oscilloscope and function generator,without laptops or proprietary software.

Innovation Point 3:Dual-Mode Feedback Compatibility

The module natively supports both half-bridge(3-wire)and full-bridge(4-wire)LVDTs,as well as resistive potentiometers,through internal jumper settings—maximizing flexibility across retrofit and new-build projects.

Innovation Point 4:Integrated Diagnostic Safeguards

Built-in monitoring detects sensor disconnection,short circuits,and valve coil faults,triggering a safe shutdown output(relay contact)to halt upstream machinery—enhancing functional safety in unattended test cells or presses.

Application Cases and Industry Value

In a North American steel service center,a 2,000-ton cut-to-length line suffered edge burr defects due to inconsistent shear blade positioning.Retrofitting the hydraulic shear actuator with a REXROTH VT-HNC100-1-22/W-08-0-0 and magnetostrictive position sensor reduced positional scatter from±2.1 mm to±0.3 mm.The card’s adjustable deceleration ramp prevented hydraulic shock during blade stop,extending seal life by 3×.Annual scrap costs dropped by$380,000—proving that precision hydraulics starts with intelligent analog control.

Similarly,in an aerospace fatigue test rig,eight REXROTH VT-HNC100-1-22/W-08-0-0 modules synchronized wing flap actuators under cyclic loading.Their analog nature ensured perfect phase alignment across axes—something digital controllers struggled with due to task scheduling latency.The system ran 24/7 for 18 months without recalibration,validating the module’s long-term drift stability(<0.1%over temperature).

Related Product Combination Solutions

REXROTH 4WRPEH 10 C4 B/M-24K24/A1M–High-response proportional directional valve driven by REXROTH VT-HNC100-1-22/W-08-0-0

REXROTH HM15-100P10–Magnetostrictive linear position transducer compatible with the module’s feedback input

REXROTH VT-MSPA1-1–Digital successor with CANopen interface for modernized architectures

REXROTH IndraControl L15–Modular PLC system that provides±10 V setpoints to multiple REXROTH VT-HNC100-1-22/W-08-0-0 cards

REXROTH ZDC-001–Signal conditioning terminal block for LVDT wiring integrity

REXROTH AB31-13/24VDC–24V power supply unit rated for motion control cabinets

REXROTH VT-HACD-1-1–Analog diagnostic display for real-time monitoring of setpoint/error signals

Installation,Maintenance,and Full-Cycle Support

Installation of the REXROTH VT-HNC100-1-22/W-08-0-0 requires secure DIN-rail mounting in a ventilated cabinet,away from high-power AC lines.Use shielded twisted-pair cables for all analog signals,with shields grounded at the controller end only.During commissioning,start with conservative PID gains and gradually increase while monitoring for oscillation—use the test point pins on the module to probe actual error voltage with an oscilloscope.

Maintenance is minimal but critical:periodically verify potentiometer positions haven’t drifted due to vibration,inspect terminal tightness,and validate sensor continuity.If the fault relay trips,check for LVDT open circuits or valve coil shorts before resetting.The module contains no user-serviceable components—failed units should be replaced as a whole.

We supply only factory-tested REXROTH VT-HNC100-1-22/W-08-0-0 units,each validated for linearity(<0.5%full scale),offset drift(<10 mV over 8 hours),and step response time(<2 ms).Every module includes calibration documentation and is backed by 18-month warranty.Our technical team offers tuning templates for common applications(presses,test stands,simulators)and can assist with signal compatibility checks for legacy sensors.

UFC921A101 3BHB024855R0101 UFC911B106 3BHE037864R0106 UDC920BE01 3BHE034863R0001 XVC770BE101 3BHE021083R0101 KUC755AE105 3BHB005243R0105 LXN1604-6 3BHL000986P7000 LWN2660-6E 3BHL000986P7002 UFC789AE 38HE014022P102 3BHL000734P0003 SLOV4.6/5.3 HIES308461R0012 HIES208441R.. ID8A92485001/022 3BHB009410R000 SG000247 3BHL000986P1006 XVC724BE101 3BHE009017R0102 DKTFM418B 3BHB015651P0001 PU180/63E 3BHB00916230001 HIES308461R0012 FPX86-9345–B 3BHL000986P0006 3BHL000734P0003 SLOV4.6/5.3 UFC921A101 3BHE024855R0101 PPC907BE101 3BHE024577R0101 XVC724BE101 3BHE009017R0102 IEC60129,62271-102 MI-CONP KUC755AE105 3BHB005243R0105 HIES308461R0012 MG160MD2-42FF300-F1 PTC 160℃ TP211 MG160MD2-42FF300-F1 ABB S-073N ALU 3BHB009884R5211 ABB S-093H 3BHB030478R0309 ABB S-123H 3BHB030479R0512 ABB UFC912A101 3BHE039426R0101 ABB 5SHY4045L0001 3BHB018162R0001 ABB S-113N 3BHB018008R0001 W4 KUC755AE105 3BHB005243R0105 HIEE401807R0001 3BHB046719R0008 STRAUB FLEX1L TB820V2 S-053M 3BHB012897R003 *12 3BHB014556R0001 3BHB010823R0002 CDP312R XVC768AE102 UFC789AE101 S-073N KU C755AE105 XVC770BE101 UFC760BE42 PPC907BE UFC760BE43 XVC769AE101 LDMTR-01 UAC389AE02 LTC391AE01 PPC905AE101 UAC383AE01 LDLPTR-01