Product Description

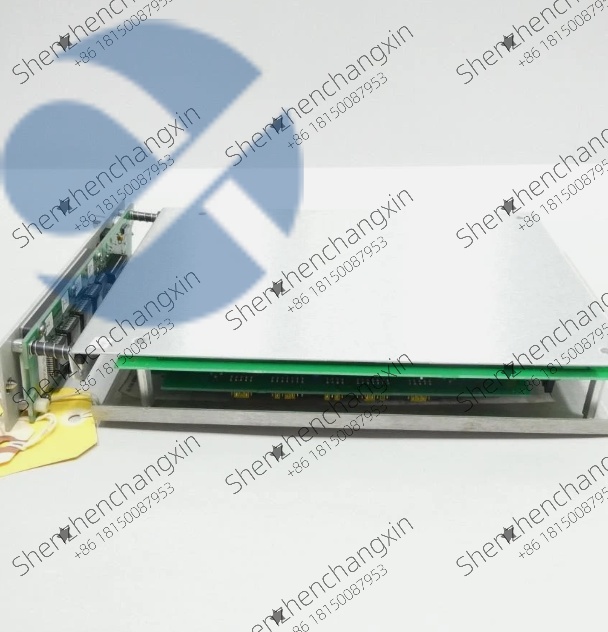

TheBENTLY 3300-50-02-01-00-00is aproximitor transducer systemdesigned for non-contact vibration and position measurement in rotating machinery.This complete sensor system includes a proximity probe,extension cable,and proximity transducer for precise monitoring of shaft vibration,axial position,and eccentricity.Engineered for critical machinery protection,it provides reliable measurement data for condition monitoring and predictive maintenance programs.

Application Scenarios

In a power generation steam turbine,theBENTLY 3300-50-02-01-00-00system monitors shaft vibration at critical bearing locations.During a scheduled outage,technicians identified a developing bearing issue through trend analysis of vibration data from the3300-50-02-01-00-00sensors.Early detection allowed for planned bearing replacement during the outage,preventing catastrophic failure that could have caused$2 million in damage and 30 days of unplanned downtime.

Technical Specifications

Parameter

Specification

Product Model

3300-50-02-01-00-00

Manufacturer

Bently Nevada(Baker Hughes)

Product Type

Proximitor Transducer System

Measurement Range

0-80 mils(0-2 mm)typical

Sensitivity

200 mV/mil(7.87 V/mm)

Frequency Response

0 to 10 kHz

Gap Voltage

-18 to-22 VDC

Probe Diameter

5 mm or 8 mm standard

Cable Length

5 meters or 9 meters standard

Operating Temperature

Probe:-40°C to+177°C

Power Supply

-24 VDC from monitor system

Output Signal

-2 to-18 VDC proportional to gap

Linear Range

0.020 to 0.080 inches(0.5 to 2.0 mm)

Compliance

API 670 standard

Technical Principles and Innovative Values

Eddy Current Technology:TheBENTLY 3300-50-02-01-00-00utilizes advanced eddy current principles to measure distance without physical contact,providing wear-free operation and high reliability in harsh environments

Temperature Compensation:Incorporates automatic temperature compensation to maintain measurement accuracy across the entire operating temperature range

Integrated System Design:Provides matched components(probe,cable,transducer)that are calibrated as a system,ensuring optimal performance and measurement accuracy

Application Cases and Industry Value

A petrochemical refinery implemented theBENTLY 3300-50-02-01-00-00transducer systems on their critical centrifugal compressors.Over 18 months,the vibration data collected enabled the maintenance team to detect early-stage impeller fouling and misalignment issues.The early warnings allowed for planned maintenance during production windows,reducing unplanned shutdowns by 75%and saving an estimated$1.2 million annually in lost production and emergency repair costs.

Related Product Combination Solutions

BENTLY 3300/46:Dual Channel Proximitor Transducer

BENTLY 3300/16:Proximitor Power Supply

BENTLY 3300/20:Proximitor Extension Cable

BENTLY 3300/25:Proximitor Mounting Hardware

BENTLY 3500:Machinery Protection System

BENTLY System 1:Condition Monitoring Software

Installation,Maintenance,and Full-Cycle Support

Installation Protocol:When installing theBENTLY 3300-50-02-01-00-00,ensure proper probe gap setting using a gap calibration kit.Verify cable integrity and secure all connections.Follow manufacturer’s guidelines for probe orientation and mounting torque to prevent measurement errors.

Maintenance Strategy:Perform quarterly calibration verification and cable resistance checks.Monitor trend data for gradual changes indicating probe or cable degradation.Replace complete transducer systems as matched sets to maintain measurement accuracy.

Technical Support Commitment:We provide comprehensive support forBENTLY 3300-50-02-01-00-00systems including installation guidance,calibration services,and troubleshooting.Our inventory includes factory-calibrated replacement kits with full traceability.

Contact our vibration monitoring specialists for technical consultation and reliable sourcing of BENTLY 3300-50-02-01-00-00 transducer systems.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!