Description

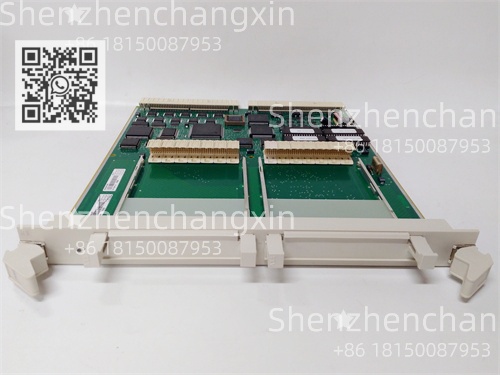

TheABB SC560 3BSE008105R1is a high-performance system controller designed for ABB’s industrial automation systems.This robust controller provides reliable processing power for complex control applications,ensuring optimal performance in demanding industrial environments across various sectors including process industries,manufacturing,and energy management.

Application Scenarios

In a large chemical processing facility,theABB SC560 3BSE008105R1managed critical batch processes with precise timing and sequencing control.During a complex multi-stage production run,the controller maintained synchronization across 15 processing units,reducing batch cycle time by 18%while improving product consistency.The system’s fault-tolerant design ensured continuous operation during a power disturbance,preventing a potential$500,000 production loss.

Parameter

Main Parameters

Value/Description

Product Model

SC560

Manufacturer P/N

3BSE008105R1

Manufacturer

ABB

Product Category

System Controller

Processor

High-performance multi-core CPU

Memory

2GB RAM,8GB Flash storage

Communication

Dual Ethernet ports,PROFIBUS,PROFINET

I/O Capacity

Supports up to 50,000 process points

Operating Temperature

0°C to+60°C

Power Supply

24V DC redundant input

Protection Rating

IP20

Certifications

UL,CE,cULus,IEC 61131-2

MTBF

>200,000 hours

Technical Principles and Innovative Values

Innovation Point 1:TheABB SC560 3BSE008105R1features advanced multi-core processing technology that enables parallel execution of control tasks,reducing scan times by up to 40%compared to previous generation controllers.This enhanced processing power supports complex control algorithms while maintaining deterministic performance.

Innovation Point 2:Integrated cybersecurity features including user authentication,audit trails,and communication encryption protect against unauthorized access and cyber threats.The controller’s secure boot mechanism and firmware validation ensure system integrity throughout its operational lifecycle.

Innovation Point 3:Redundant architecture support with hot-swappable components enables continuous operation during maintenance or component failure.The controller’s automatic failover capability ensures uninterrupted process control with switchover times of less than 100ms.

Application Cases and Industry Value

Case Study:Automotive Manufacturing Plant

An automotive assembly plant implementedABB SC560 3BSE008105R1controllers to coordinate robotic welding stations and conveyor systems.The controllers’high-speed processing enabled synchronization of 45 robots across 3 production lines,increasing throughput by 22%while maintaining positioning accuracy within±0.1mm.The system’s diagnostic capabilities reduced troubleshooting time by 60%,contributing to an overall equipment effectiveness(OEE)improvement of 15%.

Related Product Combination Solutions

SC520:Compact controller for smaller applications

CI871:Communication interface for network expansion

SD822:System expansion modules for I/O extension

TU830:Operator interface terminals

CP635:Control panel solutions

Installation,Maintenance,and Full-Cycle Support

Installation and Maintenance:TheABB SC560 3BSE008105R1mounts in standard control cabinets with DIN rail mounting.Installation requires proper power conditioning and grounding to ensure optimal performance.Configuration utilizes ABB’s Automation Builder engineering environment for efficient project implementation.

Routine maintenance includes quarterly system diagnostics and firmware updates.The controller’s comprehensive self-monitoring capabilities provide early warning of potential issues,while modular design facilitates quick component replacement when necessary.

We provide comprehensive technical support for theABB SC560 3BSE008105R1,including installation guidance,configuration assistance,and troubleshooting.Our inventory includes genuine controllers with full testing and documentation.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!