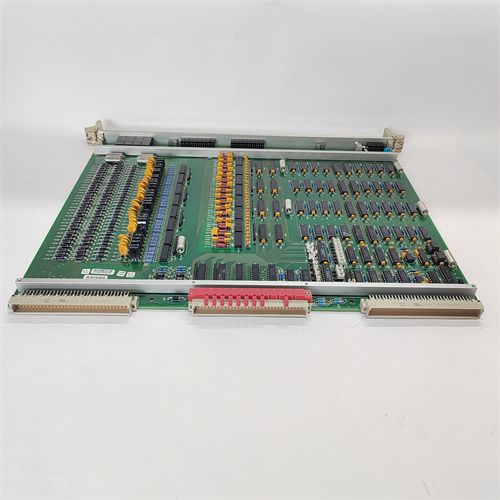

Description

The ABB IMSPM01 is an intelligent communication and monitoring interface module designed for the ABB AC 800M distributed control system. It provides direct, protocol-native connectivity to ABB’s PST and PSTB series soft starters, enabling real-time access to operational parameters such as motor current, torque, thermal load, start/stop status, and fault codes. By eliminating the need for discrete I/O wiring or third-party gateways, the IMSPM01 transforms soft starters from standalone devices into fully integrated assets within the 800xA automation ecosystem.

Application Scenarios

At a municipal wastewater treatment plant in Sweden, operators faced repeated mechanical stress on large sludge pumps due to high inrush currents during direct-on-line (DOL) starts. After retrofitting with ABB PSTB soft starters, they initially monitored only basic run/fault signals via hardwired contacts—missing critical insights like ramp time deviations or thermal buildup. The installation of the ABB IMSPM01 changed everything: now, every pump start is logged with full current profiles, and abnormal torque spikes trigger early warnings. When one pump showed a 22% increase in starting current over three weeks, maintenance replaced worn impeller bearings before seal failure occurred—avoiding a $ 90.000 environmental incident. The IMSPM01 turned soft starters into intelligent sentinels of mechanical health.

Parameter

表格

Technical Principles and Innovative Values

Innovation Point 1: Direct Protocol Translation – The IMSPM01 natively interprets ABB PST/PSTB Modbus registers, converting raw hex values into engineering units (e.g., amps, % load)—eliminating custom script development.

Innovation Point 2: Multi-Starter Aggregation – A single IMSPM01 can monitor up to 62 soft starters (31 per RS-485 port), drastically reducing I/O count and cabinet space versus point-to-point wiring.

Innovation Point 3: Predictive Diagnostics – By tracking thermal accumulation trends and current harmonics, the IMSPM01 enables condition-based maintenance—flagging issues like voltage imbalance or mechanical binding before failure.

Innovation Point 4: Energy & Performance Benchmarking – Start energy (kWh/start) and ramp efficiency data from the IMSPM01 feed into 800xA dashboards, supporting sustainability KPIs and motor optimization programs.

Application Cases and Industry Value

In a beverage bottling facility in Brazil, 48 filler and labeler motors were upgraded with PSTB soft starters to reduce mechanical shock. Initially, only “Running” and “Fault” signals were brought to the DCS. After deploying the ABB IMSPM01. engineers discovered that 12 motors were consistently exceeding recommended ramp times due to incorrect settings. Correcting these reduced average start energy by 18%, saving ~ $ 14.000 annually in electricity. More importantly, bearing failures dropped by 60% over 12 months—validating the link between controlled acceleration and mechanical longevity.

Similarly, at a district heating plant in Denmark, the IMSPM01’s real-time thermal load data prevented a cascade trip during a cold snap: when primary pump thermal levels approached 95%, the system auto-delayed non-critical secondary pump starts, keeping the network stable without operator intervention.

Related Product Combination Solutions

ABB PSTB370-600-70: High-power soft starter commonly monitored by the IMSPM01 in pump and fan applications.

ABB AC 800M PM864 (3BSE018161R1): Controller that hosts the IMSPM01 and executes motor sequencing logic.

ABB 800xA System 800: Visualizes soft starter data with trend charts, alarm lists, and performance reports.

ABB Motor Management Library: Pre-engineered function blocks that use IMSPM01 data for auto-start sequences and interlocks.

ABB IMCIS01: Complementary module for conventional motor starters; used alongside IMSPM01 in hybrid MCCs.

ABB CI854A: Communication module that can forward IMSPM01 data to enterprise systems via OPC UA.

ABB Ability™ Asset Performance Management: Cloud platform for cross-plant soft starter health scoring using IMSPM01 telemetry.

ABB TB820 I/O Baseplate: Standard mounting platform for the IMSPM01 in AC 800M racks.

Installation, Maintenance, and Full-Cycle Support

Installing the ABB IMSPM01 requires connecting two RS-485 cables (A/B) from the module to the PST/PSTB soft starters in a daisy-chain topology, using shielded twisted-pair cable (e.g., Belden 3105A). Each soft starter must be assigned a unique Modbus address (1–31) via its keypad. In Control Builder M, engineers select the “IMSPM01” hardware type, define the connected starters, and auto-generate I/O tags—no manual register mapping needed.

For maintenance, the IMSPM01 supports online diagnostics: LED indicators show communication activity and fault status, while 800xA provides detailed event logs. We recommend annual verification of baud rate consistency and termination resistor integrity on RS-485 lines.

All IMSPM01 units we supply are genuine ABB products, factory-tested with live PSTB devices to confirm data accuracy and communication stability. Each comes with a 12-month warranty, complete test report, and ready-to-import 800xA graphics library. Our team offers remote commissioning support and training on interpreting soft starter health metrics.

Contact us for a customized solution—whether you’re automating a new pumping station or modernizing legacy motor control, the ABB IMSPM01 delivers deep visibility, energy savings, and extended equipment life through intelligent soft starter integration.