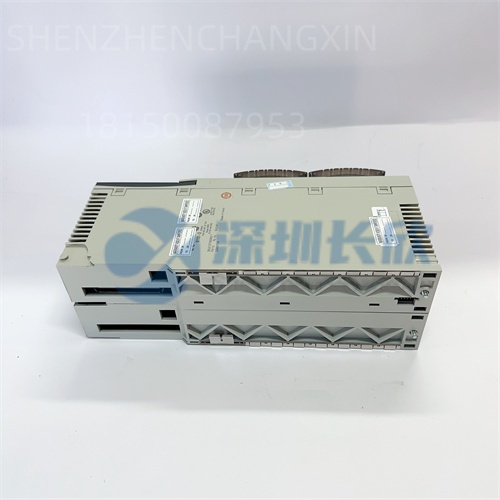

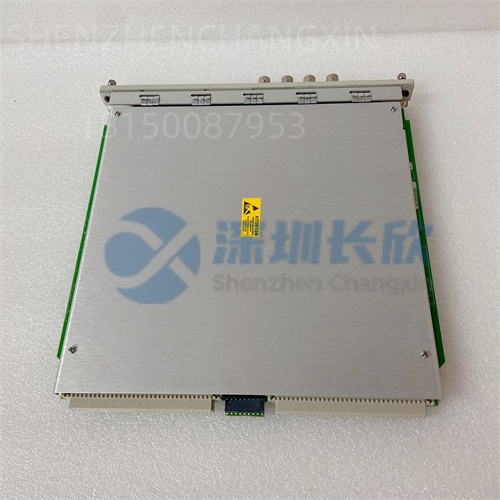

Product Overview

The TRICONEX 4329is a dedicated communications coprocessor module for the Triconex Tricon V9 and V10 series of Triple Modular Redundant(TMR)Safety Instrumented Systems(SIS).As a seasoned engineer who has commissioned numerous critical safety systems in refineries and offshore platforms,I’ve witnessed firsthand how expanding a Tricon system beyond a single chassis necessitates robust,deterministic networking.The TRICONEX 4329fulfills this vital role.While the Main Processor(e.g.,TRICONEX 4351B)handles safety logic execution,the 4329is specifically architected to manage high-speed,peer-to-peer communication over dedicated networks like TriNet,offloading this intensive task from the main CPU.This specialization ensures that critical safety scans are not hindered by network traffic management,preserving the deterministic performance that is the hallmark of a certified SIL 3 system.Essentially,it acts as the system’s”communications officer,”establishing reliable data highways between multiple Tricon nodes or to external supervisory systems.

Its core function revolves around expanding system capacity and enabling distributed control architectures.In a large facility,safety functions are often distributed geographically—for example,a wellhead shutdown system separated from a central compression station.The TRICONEX 4329allows these physically separate Tricon chassis to share data seamlessly and reliably,appearing as a single,cohesive safety system to the operator.More than just a data pipe,it implements the same TMR principles in its communication paths,ensuring messages are sent and received redundantly to guard against network faults.For engineers designing complex,multi-node safety architectures,the TRICONEX 4329is not an optional accessory;it is a foundational component that enables the scalability and geographical distribution required for modern,large-scale industrial facilities while rigorously maintaining the integrity of the safety loop.

Technical Specifications

Parameter Name

Parameter Value

Product Model

TRICONEX 4329

Manufacturer

Triconex(Schneider Electric)

Product Type

Communications Coprocessor Module

Compatible System

Tricon V9,V10 Series TMR Safety System

Primary Function

High-speed peer-to-peer communication and I/O coprocessing

Network Support

Primarily designed for TriNet(Triconex proprietary peer-to-peer network)

Communication Role

Enables communication between multiple Tricon chassis(nodes)

Architecture Integration

Integrates with the chassis’triple bus,operating in a TMR fashion

Hot Swap Capable

Yes,supports online insertion and removal when following proper procedures

Status Indication

Front-panel LEDs for power,active status,and fault conditions

Slot Compatibility

Occupies a dedicated coprocessor slot in the Tricon chassis

Power Supply

Powered by the Tricon chassis backplane

Operating Temperature

0°C to 60°C(Standard for control room environments)

Diagnostics

Continuous self-diagnostics;faults reported to the Main Processor

Main Features and Advantages

Dedicated Coprocessing for Uncompromised Performance:The most significant advantage of the TRICONEX 4329is its role as a dedicated communications specialist.By offloading the demanding tasks of network protocol management and inter-chassis data exchange from the Main Processor,it ensures that the critical safety logic scan times remain fast and deterministic.In a SIL 3 system,predictable performance is non-negotiable.The 4329guarantees that expanding your system with additional I/O or remote nodes does not introduce unpredictable delays or jitter that could affect the system’s ability to respond within its required safety time.This architectural separation of concerns is a key reason why Tricon systems maintain their performance and certification in large,distributed applications.

Enabling Scalable and Distributed Safety Architectures:The module is the key enabler for building truly distributed TMR safety systems.Through networks like TriNet,the TRICONEX 4329allows up to 64 Tricon nodes to communicate,sharing global data points as if they were in the same chassis.This allows for elegant system design where safety functions can be localized to process areas(reducing wiring costs and complexity)while still participating in plant-wide safety sequences.For example,a turbine overspeed trip in a power generation island can trigger a coordinated unit shutdown sequence managed by a separate Tricon node overseeing balance-of-plant safety.This distributed intelligence,coordinated by the 4329,creates a resilient safety network far superior to a single,monolithic controller with miles of home-run cabling.

High-Availability and Fault-Tolerant Communications:True to the Triconex philosophy,the communications managed by the 4329are not single-threaded.When used in redundant network configurations,it supports the creation of dual,independent communication paths.Data is sent across both paths,and the receiving 4329module validates and votes on the incoming information,providing fault tolerance for the communication link itself.This means a single network cable cut or a fault in one network interface will not stop inter-chassis communication,preserving the overall system’s availability and functional integrity.This level of network redundancy is critical for safety systems protecting continuously operating multi-billion dollar assets.

Application Field

The TRICONEX 4329is employed in large-scale,complex Safety Instrumented Systems where safety control is distributed across multiple geographic areas or requires extensive I/O capacity exceeding a single chassis.

In a sprawling liquefied natural gas(LNG)export terminal,separate Tricon chassis may protect the refrigeration compressors,the LNG storage tanks,and the loading docks.The TRICONEX 4329modules in each chassis link them via TriNet,allowing a high-pressure alarm at a compressor to initiate a safe shutdown sequence that cascades to the storage and loading systems,all while maintaining the required SIL 3 integrity.Similarly,in an offshore production platform,one Tricon node may handle the subsea wellhead safety valves,another the topsides process ESD,and a third the fire and gas system.The 4329modules create a unified”safety nervous system,”enabling a fire detection signal to automatically initiate well shutdown and process isolation.

In power generation,particularly in combined-cycle gas turbine(CCGT)plants,one Tricon system may be dedicated to turbine overspeed protection(TSI),while another manages the boiler protection and burner management system(BMS).The TRICONEX 4329facilitates the high-speed data exchange needed for coordinated turbine-generator trip sequences,ensuring that all plant equipment responds in a safe,synchronized manner during a fault.Its use is a hallmark of large,integrated safety projects in oil&gas,petrochemicals,and power generation.

Related Products

TRICONEX 4351B:The Main Processor module that relies on the 4329for offloaded communication tasks.

TRICONEX 4300M:Another model of comms coprocessor,often a predecessor or variant within the same family.

TRICONEX 4361:An enhanced comms coprocessor for later Tricon versions,offering additional functionality.

TRICONEX TCM(Tricon Communication Module):Various modules(e.g.,for Modbus,Ethernet)that connect to the coprocessor slot or main bus for external communication.

TriNet Cabling and Repeaters:The specialized cabling and signal boosters used to establish the physical network between TRICONEX 4329modules in different chassis.

TRICONEX Chassis(e.g.,8101,8201):The physical enclosures that house the 4329,main processor,and I/O modules.

TriStation 1131 Software:The engineering environment where the network configuration and global data exchange between nodes using the 4329is defined.

Installation and Maintenance

Pre-installation preparation:Installing a TRICONEX 4329module requires careful system planning.First,confirm the target chassis slot is designated for a comms coprocessor and is compatible with the V9/V10 series.The most crucial step is pre-configuring the TriNet network parameters(node addresses,data exchange tables)in the TriStation 1131 software project.This configuration must be compiled and ready for download.For a live system,a detailed safe work procedure and management of change(MOC)authorization are mandatory.Have the correct TriNet cables and terminators on hand,and ensure the new module’s firmware revision is compatible with the rest of the system.

Maintenance recommendations:The TRICONEX 4329is designed for long-term reliability.Routine maintenance consists of monitoring its health via the TriStation 1131 diagnostics.Pay attention to any recurring communication errors or fault LEDs on the module faceplate,which could indicate network cable issues,termination problems,or a failing module.The hot-swap capability allows for replacement.The procedure is critical:place the specific chassis slot into Programmode via the software,gently remove the old 4329,insert the new one firmly,and then return the slot to Runmode.The system will automatically integrate the new module.Always verify network connectivity and data exchange after any maintenance.Keeping a pre-configured spare 4329is a strategic best practice for minimizing downtime during failure events.

Product Guarantee

We guarantee that every TRICONEX 4329communications coprocessor module we supply is a genuine Triconex(Schneider Electric)component,sourced with full traceability to ensure authenticity and performance integrity.Each module undergoes a rigorous validation process,including inspection for physical damage,verification of factory markings,and functional power-on testing where feasible.We understand that this module serves as a critical communications nexus in your TMR safety system,where reliability directly impacts overall plant safety and availability.Our technical specialists provide support for compatibility verification with your existing Tricon chassis and system software.Backed by a substantive warranty and our commitment to excellence,we provide reliable,authentic components that help you maintain the uncompromising safety and operational standards demanded by your critical industrial processes.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

![]()

![]()