📄 Product Overview

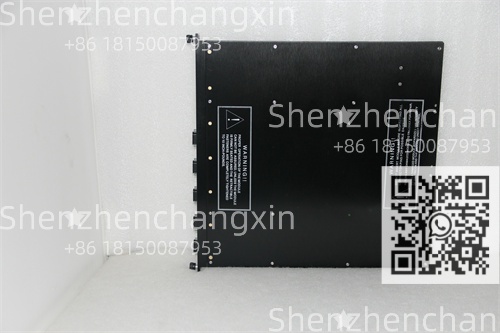

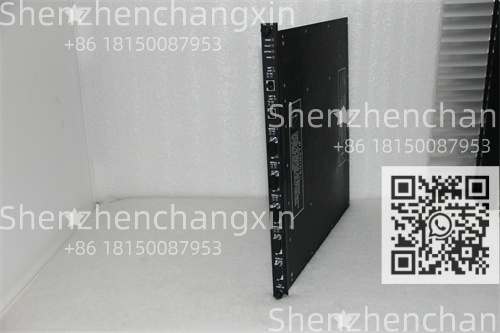

The Triconex 4351B is an 8-slot main chassis (also called a rack or backplane) for the Tricon® Triple-Modular Redundant (TMR) Safety Instrumented System (SIS) platform by Schneider Electric (formerly Invensys Triconex). It serves as the physical and electrical backbone of the Tricon safety controller—housing redundant power supplies, three main processor modules (CPUs), communication cards, and I/O modules (digital/analog input/output).

Designed for mission-critical applications, the 4351B enables continuous, fault-tolerant operation in industries such as oil & gas, refining, chemicals, power generation, and pharmaceuticals.

🏭 Typical Application Scenario

At a hydrogen production plant in Germany, a legacy relay-based emergency shutdown (ESD) system was replaced with a Triconex system built around the 4351B chassis. The rack was populated with:

Three 3211E main processors (TMR)

Dual 4329A power supplies (redundant 24 V DC)

3664 digital input modules (for pressure/temperature switches)

3805E digital output modules (for solenoid valves)

A 3701E communication module (for EDM monitoring)

During commissioning, engineers performed a live CPU swap—removing one 3211E while the system remained online. The 4351B’s backplane seamlessly rerouted signals through the remaining two processors, maintaining full safety functionality. Over five years, the system achieved zero spurious trips and passed all SIL 3 audits. “The 4351B isn’t just a rack—it’s the foundation of our process safety,” said the plant’s automation lead.

⚙️ Key Technical Specifications

表格

💡 Technical Advantages & Innovations

✅ True Triple-Modular Redundancy (TMR) Backplane

The 4351B routes three independent signal paths between CPUs and I/O—ensuring no single point of failure. Even if one backplane trace fails, voting logic maintains integrity.

✅ Hot-Swap Ready

All modules—including power supplies, CPUs, and I/O—can be replaced without powering down the system, maximizing uptime.

✅ Deterministic Performance

Fixed scan cycle (typically 25–100 ms) ensures predictable response for time-critical safety actions.

✅ Robust Mechanical Design

Heavy-duty metal enclosure, conformal-coated backplane, and secure module latching for harsh industrial environments.

✅ Scalable within Limits

While only 8 slots, multiple 4351B chassis can be networked via TriBus or Ethernet for larger applications.

🔗 Commonly Paired Components

表格

🔧 Installation & Maintenance Best Practices

Grounding: Bond chassis to plant ground grid using ≥6 AWG wire—critical for noise immunity and safety.

Power Wiring: Use separate, fused 24 V DC feeds for each power supply in redundant setups.

Module Seating: Ensure all modules are fully latched—partial insertion causes intermittent faults.

Ventilation: Allow ≥100 mm clearance on all sides for convection cooling.

Diagnostics: Monitor chassis health via EDM—alerts include power loss, module removal, or backplane errors.

⚠️ Obsolescence & Lifecycle Status

The 4351B is part of the mature Tricon v10/v11 platform. While no longer sold as new in some regions, it remains:

Supported by Schneider Electric for repairs and firmware

Available via refurbished/exchange programs

Eligible for long-term support agreements (up to 2030+ in many cases)

🔁 Migration Path: For new projects, consider Triconex eXP or EcoStruxure™ Foxboro DCS with Safety—but the 4351B is still viable for brownfield expansions.

✅ Summary

The Triconex 4351B is far more than a metal box—it’s the fault-tolerant heart of one of the world’s most trusted safety platforms. By integrating redundant power, processing, and I/O into a single deterministic architecture, it delivers unmatched reliability for protecting people, assets, and the environment.

🔒 In functional safety, the chassis is the castle. The 4351B keeps the gates locked—and the kingdom safe.

Need help sourcing, configuring, or migrating from a 4351B system? Contact a Schneider Electric Triconex-certified partner or functional safety specialist for engineering support.