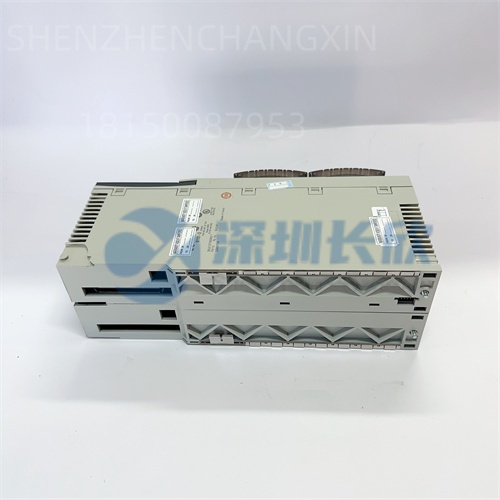

Product Overview

The VIBRO-METER MPC4 200-510-078-115 is a high-precision,modular condition monitoring and protection card engineered for continuous surveillance of rotating machinery in critical industrial applications such as power generation,oil&gas,and heavy process industries.Developed by VIBRO-METER®—a legacy brand now fully integrated into Collins Aerospace(RTX)—this module serves as a core component within the Vibro-Meter MMS 6000 or MMS 3000 machinery monitoring systems,delivering real-time vibration analysis,bearing temperature tracking,and shaft position measurement with exceptional signal fidelity and diagnostic depth.The VIBRO-METER MPC4 200-510-078-115 supports up to four independent channels of dynamic input(e.g.,from eddy-current proximity probes or accelerometers),enabling comprehensive assessment of radial vibration,axial thrust position,and differential expansion on turbines,compressors,pumps,and generators.

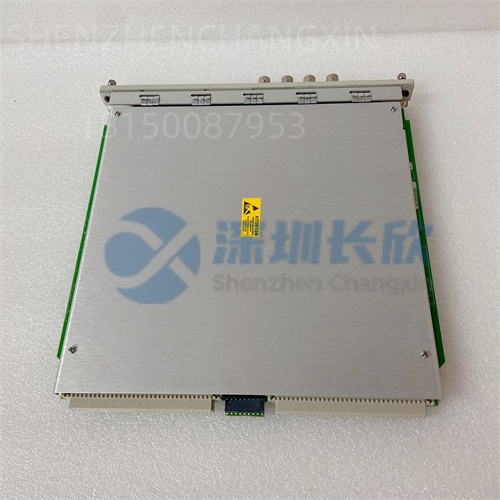

Designed for integration into 19-inch rack-based monitoring cabinets,the VIBRO-METER MPC4 200-510-078-115 combines analog front-end precision with digital processing intelligence,featuring anti-aliasing filters,programmable gain amplifiers,and 24-bit A/D conversion to capture subtle mechanical anomalies long before catastrophic failure occurs.Its firmware supports advanced algorithms including peak-to-peak,RMS,and true peak detection,along with user-configurable alarm logic(warning/danger thresholds with time delays)that interfaces directly with plant safety systems via relay outputs or fieldbus protocols.As part of the globally trusted Vibro-Meter ecosystem—known for compliance with API 670 standards—the VIBRO-METER MPC4 200-510-078-115 ensures operational integrity in environments where unplanned downtime can cost millions per hour.Whether deployed in a nuclear power station’s main coolant pump or an offshore LNG compressor train,this module delivers the reliability,accuracy,and diagnostic transparency demanded by modern asset performance management strategies.

Technical Specifications

Parameter Name Parameter Value

Product Model MPC4 200-510-078-115

Manufacturer VIBRO-METER®(Collins Aerospace/RTX)

Product Type 4-Channel Modular Protection and Monitoring Card

Compatible System MMS 6000/MMS 3000 Machinery Monitoring System

Input Channels 4 dynamic analog inputs(differential or single-ended)

Supported Sensor Types Eddy-current proximity probes(displacement),accelerometers(vibration),velocity sensors

Input Range±10 V full scale(configurable per channel)

Signal Conditioning Anti-aliasing filter(programmable cutoff),gain adjustment,DC offset compensation

A/D Resolution 24-bit sigma-delta converter

Sampling Rate Up to 10 kHz per channel(real-time FFT capable in system context)

Output Relays 2 programmable SPDT relays per channel(alarm/trip)

Operating Temperature 0°C to+60°C

Power Supply+24 V DC via backplane(typical 3.5 W consumption)

Certifications CE,UL,CSA,ATEX(when installed in certified system enclosures)

Main Features and Advantages

API 670 Compliance for Critical Machinery Protection:The VIBRO-METER MPC4 200-510-078-115 is engineered to meet the stringent requirements of API Standard 670 for machinery protection systems,ensuring reliable trip decisions based on validated vibration and position criteria—essential for safeguarding multi-million-dollar turbomachinery in refineries and power plants.

True Dual-Function Architecture:Unlike basic I/O cards,this module performs both real-time protection(with hardwired relay outputs for direct trip interface)and high-fidelity data acquisition for trending and diagnostics.This eliminates the need for separate protection and monitoring systems,reducing lifecycle costs and integration complexity.

Advanced Signal Integrity for Sub-Micron Measurements:With ultra-low noise front-end circuitry and precision filtering,the VIBRO-METER MPC4 200-510-078-115 resolves shaft movements as small as 0.1µm—critical for detecting early-stage rubs,misalignment,or oil whirl in high-speed centrifugal compressors operating above 10,000 RPM.

Flexible Configuration via MMS Software Suite:Engineers can define custom alarm logic(e.g.,“trip if X-axis vibration>80µm AND Y-axis>70µm for 2 seconds”)using the MMS Configurator tool.Each channel supports independent scaling,filtering,and alarm hysteresis,adapting to diverse machine types within the same cabinet.

Robust Industrial Design with Diagnostics:Built-in self-test functions monitor power rails,A/D health,and relay coil integrity.Any internal fault triggers a system-level“module fail”alarm,ensuring fail-safe behavior per IEC 61508 SIL 2 principles when used in safety-critical configurations.

Application Field

The VIBRO-METER MPC4 200-510-078-115 is widely deployed in applications where continuous,fail-safe monitoring of rotating equipment is non-negotiable.In combined-cycle power plants,it protects gas and steam turbine-generator sets by tracking radial vibration on journal bearings and axial position of thrust collars—parameters directly tied to rotor stability during load ramps or grid disturbances.In upstream and midstream oil&gas,the module monitors centrifugal compressors in gas reinjection or pipeline transport systems,where imbalance or surge can lead to seal damage and hazardous leaks.

It is also essential in petrochemical facilities for ethylene crackers,ammonia synthesis loops,and cryogenic expanders,where machines operate under extreme temperatures and pressures.Nuclear power stations use the VIBRO-METER MPC4 200-510-078-115 on reactor coolant pumps due to its proven reliability and electromagnetic compatibility in high-radiation zones.Additionally,hydroelectric plants employ it on generator guide bearings to detect cavitation-induced vibration.Because the MMS platform supports seamless integration with DCS(via Modbus TCP or OPC UA)and enterprise asset management systems,the VIBRO-METER MPC4 200-510-078-115 not only prevents trips but also feeds predictive maintenance models with high-resolution waveform and spectrum data.

Related Products

MPC8 200-510-078-115:8-channel version of the same series;doubles density for large machines with many bearings.

TPU 200-510-078-115:Tachometer Processing Unit;provides speed reference for order analysis and runout compensation.

MMS 6810 Rack:Main chassis for MMS 6000 system;houses up to 12 modules including MPC4 200-510-078-115.

DIO 200-510-078-115:Digital I/O module;handles auxiliary alarms and external reset signals.

Vibro-Meter VM600:Legacy monitoring system;predecessor to MMS 6000;uses similar but non-interchangeable cards.

MMS Configurator/Analyzer Software:Official tools for setup,calibration,and spectral diagnostics.

Proximity Probe System(e.g.,PR6423/00R-010):Compatible eddy-current sensors often paired with the MPC4 200-510-078-115.

Installation and Maintenance

Pre-installation preparation:Before installing the VIBRO-METER MPC4 200-510-078-115,verify compatibility with your MMS 6000 or 3000 backplane revision and ensure the system firmware supports this hardware variant.Confirm sensor cable lengths and probe driver settings(e.g.,-24 V DC for PR6423 series)match the input configuration.Use shielded,twisted-pair extension cables with overall braid grounded at the monitoring cabinet only to avoid ground loops.

Maintenance recommendations:Perform annual calibration checks using a precision signal generator to validate alarm thresholds and scaling accuracy.Inspect terminal blocks for oxidation,especially in humid or corrosive environments.Monitor the module’s status LEDs and system logs for“channel fault”or“relay test fail”indications.The VIBRO-METER MPC4 200-510-078-115 supports hot insertion in live MMS racks,but always initiate a software“module disable”command before physical removal to prevent spurious alarms.Store spare units in static-shielded bags and avoid exposure to condensation during transit.

Product Guarantee

Every VIBRO-METER MPC4 200-510-078-115 we provide is rigorously tested for channel accuracy,relay functionality,and communication integrity using factory-grade calibration equipment traceable to NIST standards.Units are guaranteed to be genuine ex-factory or professionally refurbished to OEM specifications,with full compliance to original technical documentation.We offer a 12-month warranty covering material and workmanship defects,backed by engineering-level technical support for integration,troubleshooting,and replacement guidance.Our commitment ensures the VIBRO-METER MPC4 200-510-078-115 remains a dependable guardian of your critical rotating assets—today and throughout its operational lifecycle.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!