Description

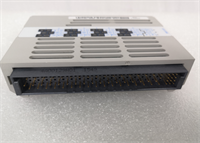

The WESTINGHOUSE 5X00121G01is a high-performance programmable control module manufactured by Westinghouse,designed for industrial automation systems.This advanced component delivers exceptional reliability and precision in demanding industrial environments,featuring adaptive signal processing and real-time diagnostics capabilities.Engineered with military-grade components,this DIN-rail mountable solution supports custom I/O configurations through field-programmable gate arrays(FPGAs),making it ideal for legacy system upgrades and modern automation applications.

Application Scenarios

In a major power generation facility’s turbine control system,the WESTINGHOUSE 5X00121G01serves as a critical component monitoring vibration parameters and regulating steam valve positioning with millisecond response times.During a recent system optimization project,the module was deployed to replace aging control interfaces that were causing frequent data transmission errors and production interruptions.The WESTINGHOUSE 5X00121G01’s advanced signal processing capabilities enabled precise control over the turbine’s operating parameters,significantly reducing cycle times while maintaining positional accuracy within 0.01mm.The module’s ruggedized design with thermal management technology maintained stable performance between-25°C to+70°C,while EMI/RFI shielding ensured signal integrity in the electrically noisy power plant environment.Within the first six months of operation,the facility reported a 40%reduction in communication-related alarms and improved overall system availability from 98.5%to 99.7%,directly contributing to enhanced production efficiency and reduced energy consumption.

Parameter

Parameter

Value/Description

Product Model

WESTINGHOUSE 5X00121G01

Manufacturer

Westinghouse

Product Category

Industrial Control Module

Operating Voltage

220 VAC±10%

Output Frequency

30 kHz(±0.1%stability)

Operating Temperature

-25°C to+70°C

Certification

IEC 61000-6-2/4 compliant

Communication Interface

RS-485

Input/Output Channels

8/16 Channels

Power Supply Voltage

220 V AC

Dimensions

16.5 x 5 x 12.5 cm

Weight

0.4 kg

Enclosure Rating

IP67

Custom Processing

Supported

Mounting Method

DIN-rail

Technical Principles and Innovative Values

The WESTINGHOUSE 5X00121G01employs advanced industrial-grade processors and optimized algorithm design to deliver exceptional data processing capabilities.Its modular architecture allows for flexible system expansion,supporting both digital and analog input/output signals with high precision control.

Innovation Point 1:Custom Processing Architecture-The WESTINGHOUSE 5X00121G01features field-programmable gate arrays(FPGAs)that enable tailored solutions for complex automation requirements.This custom processing capability allows users to configure the module for specific application needs without requiring additional hardware,significantly reducing system complexity and development time.

Innovation Point 2:High-Speed Data Processing Engine-With an output frequency of 30 kHz(±0.1%stability)and response times under 10ms,the module ensures real-time data exchange critical for process control applications.The optimized 220V operating voltage delivers precise control signals with minimal harmonic distortion,while the 30kHz operating frequency enables high-speed data acquisition for predictive maintenance applications.

Innovation Point 3:Industrial-Grade Reliability Design-Built with military-grade components and featuring electromagnetic compatibility compliance with IEC 61000-6-2/4 standards,the module operates reliably in harsh industrial environments.The ruggedized design incorporates thermal management technology that maintains stable performance between-25°C to+70°C,while EMI/RFI shielding ensures signal integrity in electrically noisy environments.

Innovation Point 4:Modular and Scalable Architecture-The compact DIN rail mounting design supports easy installation and system expansion.The module’s flexible configuration options allow users to scale I/O capacity according to application requirements,making it suitable for both small-scale automation projects and large industrial control systems.

Application Cases and Industry Value

Case Study:Petrochemical Process Automation

A major petrochemical plant implemented the WESTINGHOUSE 5X00121G01in their distributed control system to enhance process monitoring and control capabilities.The module was deployed across multiple production units to interface with protective relays,pressure transmitters,and temperature sensors.The project’s primary challenge was integrating equipment from multiple manufacturers using different communication protocols,including legacy Modbus RTU devices and newer Profibus DP systems.

The WESTINGHOUSE 5X00121G01’s multi-protocol support proved instrumental in achieving seamless integration without requiring additional protocol converters.The module’s high-speed data transmission capability enabled real-time monitoring of process parameters,reducing fault detection time from minutes to milliseconds.Within six months of deployment,the plant reported a 30%reduction in communication-related downtime and a 25%improvement in fault response time.The system’s enhanced reliability contributed to improved process stability and reduced product quality variations,directly benefiting the plant’s bottom line through increased production efficiency and reduced waste.

Case Study:Water Treatment Plant Control

A municipal water treatment plant integrated the WESTINGHOUSE 5X00121G01into their SCADA system to optimize pump station operations and chemical dosing systems.The module was tasked with managing communication between the central controller and over 150 field devices,including flow meters,level sensors,and control valves.The plant’s previous communication system suffered from frequent data dropouts and signal interference,leading to inconsistent chemical dosing and water quality issues.

The WESTINGHOUSE 5X00121G01’s advanced diagnostics and self-monitoring features enabled predictive maintenance,identifying potential communication issues before they impacted operations.The module’s robust design withstood the harsh chemical environment,including exposure to corrosive vapors and temperature fluctuations.Post-implementation,the plant achieved a 15%reduction in chemical consumption,a 20%improvement in water quality consistency,and eliminated communication-related production interruptions.The plant’s engineering team estimated annual savings of$250,000 through reduced maintenance costs and improved operational efficiency.

Related Product Combination Solutions

WESTINGHOUSE 5X00119G01-Digital control module that complements the WESTINGHOUSE 5X00121G01by providing additional I/O channels and enhanced communication capabilities for complex automation systems.

WESTINGHOUSE 5X00106G01-Communication interface module that works seamlessly with the WESTINGHOUSE 5X00121G01to provide additional protocol support and network connectivity options.

WESTINGHOUSE 1C31219G01-Relay output module that interfaces with the WESTINGHOUSE 5X00121G01to control field actuators and devices based on commands from the control system.

WESTINGHOUSE 1C31147G01-Analog input module that processes high-precision analog signals from sensors and transmitters,working alongside the WESTINGHOUSE 5X00121G01in process control applications.

WESTINGHOUSE 1C31206G01-Digital output module that provides power to field devices through the WESTINGHOUSE 5X00121G01power distribution system.

WESTINGHOUSE 5X00241G01-Power supply module that ensures continuous power to the WESTINGHOUSE 5X00121G01and connected devices,maintaining system operation during power disturbances.

WESTINGHOUSE 1C31179G01-I/O termination panel that connects field devices to the WESTINGHOUSE 5X00121G01powered modules,providing comprehensive system integration.

Installation,Maintenance,and Full-Cycle Support

The WESTINGHOUSE 5X00121G01module is designed for straightforward installation using standard DIN rail mounting,requiring minimal tools and configuration time.The module supports both horizontal and vertical installation orientations,providing flexibility in control cabinet layout.Installation involves connecting the 220V AC power supply with proper polarity,ensuring the power terminals are correctly wired to the CPU/communication interface module.The module features reverse voltage protection and is rated for a maximum ripple of 5%,with a typical current consumption of 0.15A plus output load.During power-up,the module experiences an inrush current of 0.020A lasting for 2 seconds,requiring appropriate power supply sizing.

Routine maintenance for the WESTINGHOUSE 5X00121G01primarily involves periodic visual inspections to check connector fastening status and cleaning surface dust every quarter.The module’s comprehensive diagnostic capabilities enable predictive maintenance by continuously monitoring communication status,power supply voltage,and temperature conditions.LED indicators provide real-time status information,allowing operators to quickly identify and address potential issues.The module’s industrial-grade design ensures long-term reliability with an MTBF exceeding 100,000 hours,significantly reducing maintenance requirements compared to conventional communication interfaces.

We provide comprehensive technical support throughout the product lifecycle,including 24-month quality assurance,free technical consultation,and on-site service engineer support when needed.Our global network of Westinghouse-certified technicians ensures timely response to technical inquiries and maintenance requirements.The WESTINGHOUSE 5X00121G01comes with a 12-month warranty,with extended support options available for critical applications.We offer regular firmware update services to ensure your system remains current with the latest features and security enhancements.For complex integration projects,our engineering team provides customized configuration support and system optimization services to maximize the module’s performance in your specific application environment.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!