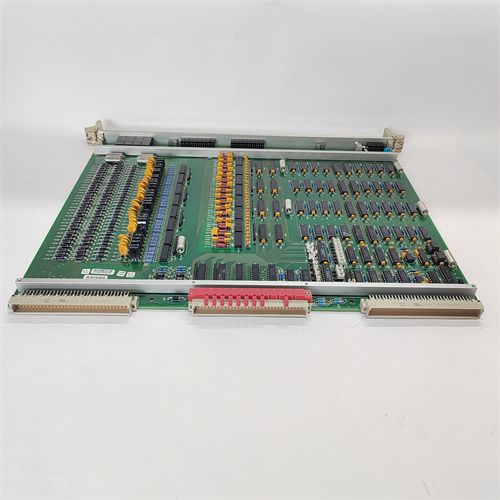

Description

The Yaskawa JEPMC-MC001 is the central motion control CPU module designed for Yaskawa’s MP2000 and MP3000 series programmable motion controllers. Serving as the “brain” of the system, it executes motion programs (written in MP Series Ladder or Motion Language), coordinates up to 62 axes via MECHATROLINK-II/III, handles I/O processing, and manages real-time communication with HMI, PLCs, and enterprise systems. Widely used in packaging, semiconductor, robotics, and material handling, the JEPMC-MC001 delivers deterministic, high-speed control with integrated logic and motion in a single platform.

Application Scenarios

At a high-speed bottling line in Germany, a legacy cam-driven filler was replaced with a fully servo-electric system using eight Yaskawa Σ-7 servos coordinated by an MP2300 controller equipped with a JEPMC-MC001 CPU. The JEPMC-MC001 executed synchronized electronic gearing and camming profiles at a 1 ms cycle time, enabling 40.000 bottles/hour with ±0.1 mm positioning accuracy. When a network glitch briefly disrupted one axis, the built-in error recovery logic—processed entirely on the JEPMC-MC001—prevented a full line stop. The machine builder credited the JEPMC-MC001’s integrated architecture for cutting development time by 50% compared to separate PLC + motion solutions.

Parameter

表格

Technical Principles and Innovative Values

Innovation Point 1: Integrated Logic + Motion in One CPU

Unlike traditional architectures requiring separate PLC and motion controllers, the JEPMC-MC001 unifies both functions—reducing latency, simplifying programming, and eliminating synchronization issues.

Innovation Point 2: MECHATROLINK Real-Time Determinism

With hardware-accelerated MECHATROLINK support, the JEPMC-MC001 achieves jitter <1 µs, enabling precise multi-axis coordination for applications like flying shears or delta robots.

Innovation Point 3: Onboard Diagnostics & Web Access

Built-in web server allows remote monitoring of axis status, alarms, and program execution via standard browser—no proprietary software required for basic diagnostics.

Innovation Point 4: Scalable from 2 to 62 Axes

The same JEPMC-MC001 can control a simple 2-axis pick-and-place or a complex 62-axis printing press—offering machine builders a single platform for diverse product lines.

Application Cases and Industry Value

In a Japanese electronics assembly factory, a flexible PCB test handler used a JEPMC-MC001-based MP2400 system to coordinate 12 servo axes for part loading, probing, and sorting. The ability to store multiple motion recipes in the JEPMC-MC001’s flash memory allowed instant product changeovers—boosting OEE by 22%. Over five years, the system achieved 99.98% uptime, with field engineers praising the module’s robustness in high-EMI environments near RF testers. The total cost of ownership was 30% lower than competing PC-based motion solutions due to reduced engineering and maintenance effort.

Related Product Combination Solutions

Yaskawa MP2300 / MP2400 / MP3300: Base controller racks—host the JEPMC-MC001 CPU

Yaskawa JEPMC-IO001: Digital I/O module—expands local I/O capacity alongside JEPMC-MC001

Yaskawa Σ-7 / Σ-5 Servo Drives: High-response drives—communicate via MECHATROLINK with JEPMC-MC001

Yaskawa MotionWorks IEC: Programming software—used to develop and debug logic/motion on JEPMC-MC001

Yaskawa JEPMC-ES300: Ethernet module—adds Modbus TCP, EtherNet/IP, or PROFINET (via gateway)

Yaskawa MP2000 HMI Options: Touch panels—integrate seamlessly via built-in web server or serial link

Yaskawa MECHATROLINK Cables & Terminals: Certified network components—ensure signal integrity for JEPMC-MC001 networks

Yaskawa SigmaWin+: Drive tuning suite—works in tandem with JEPMC-MC001 for system-level optimization

Installation, Maintenance, and Full-Cycle Support

The JEPMC-MC001 installs directly into the CPU slot of an MP2000/MP3000 backplane. After power-up, it auto-detects connected MECHATROLINK slaves and I/O modules. Programs are loaded via USB, Ethernet, or CF card. A lithium battery (replaceable every 3–5 years) preserves absolute position data during power loss.

For long-term reliability:

Ensure adequate cabinet ventilation (max ambient 55°C)

Use Yaskawa-certified MECHATROLINK cables with proper termination

Regularly back up programs using MotionWorks IEC or FTP

We supply JEPMC-MC001 units in multiple conditions:

New Surplus: Original sealed stock, full warranty

Reconditioned: Fully tested, cleaned, firmware-updated, 12-month warranty

Refurbished with Battery Replacement: Includes fresh backup battery and full functional validation

Each unit undergoes rigorous testing for boot integrity, MECHATROLINK communication, I/O scan, and motion task execution. We provide compatibility verification for your specific MP-series base and firmware version.

Contact us for a customized solution—including programming support, network topology review, or global logistics for multi-machine deployments. Keep your motion systems running with the intelligence they were engineered to rely on.