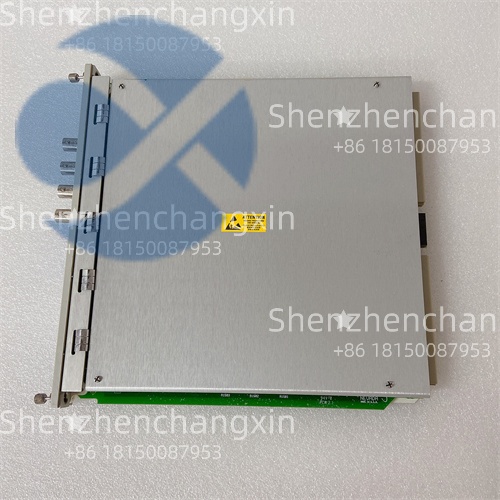

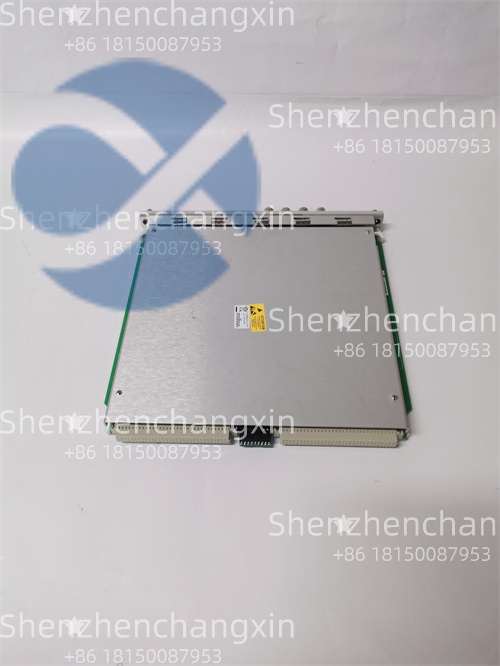

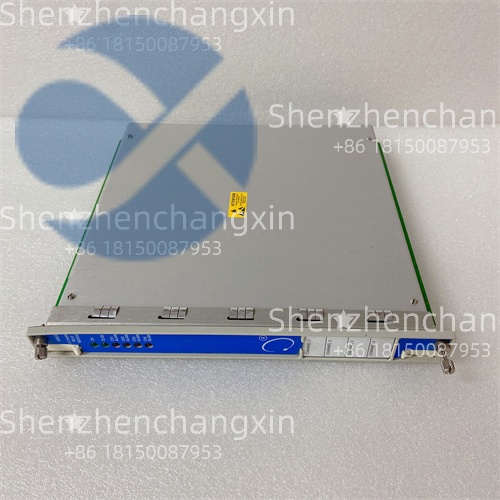

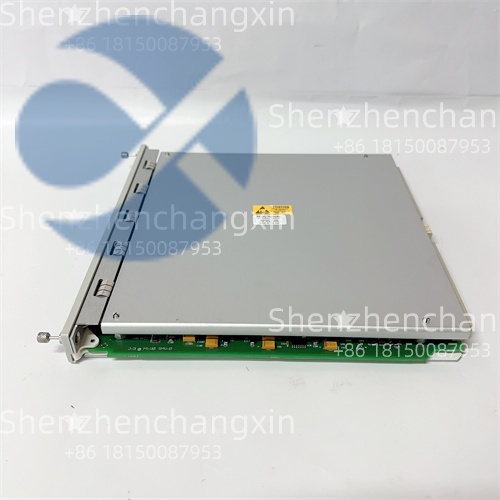

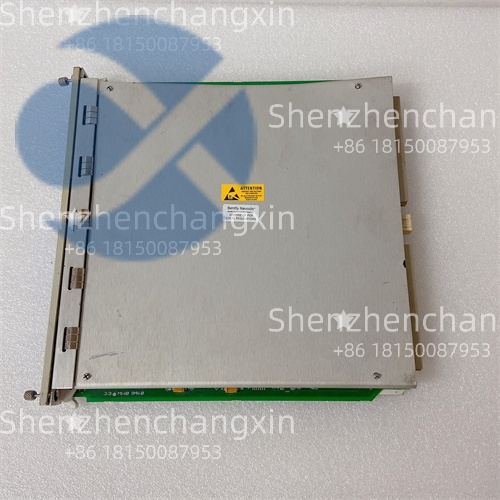

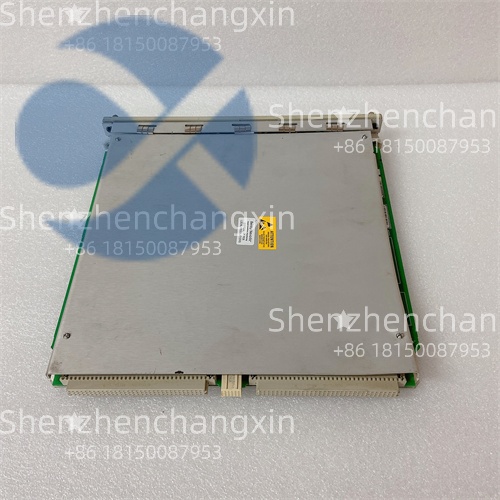

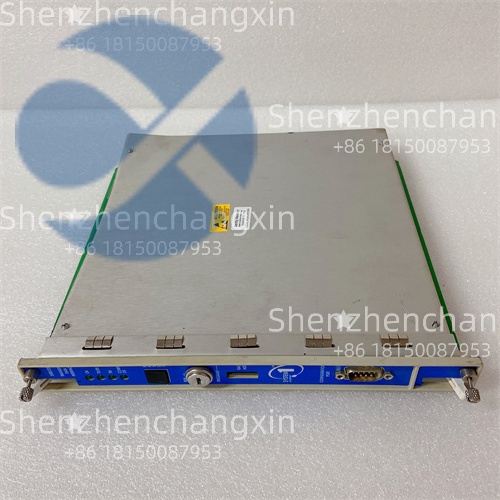

ABB 88TK50C-E: Low-Power Temp Transmitter (GJR2397000R1210) for Remote Assets

Description:

The 88TK50C-E GJR2397000R1210 is a high-precision industrial temperature transmitter from ABB,a global leader in automation and process control solutions.Designed for critical temperature sensing applications,it converts signals from RTDs(e.g.,PT100)or thermocouples into stable 4-20mA analog outputs—with HART communication for remote configuration and diagnostics.Its rugged build,wide temperature range,and compliance with industrial standards make it a trusted choice for sectors where precise temperature control directly impacts product quality,safety,and operational efficiency.

Application Scenarios:

A European pharmaceutical manufacturer faced recurring issues with vaccine production:their old temperature transmitters had±0.5%accuracy,leading to inconsistent fermentation tank temperatures(fluctuating±1.2°C).This caused 12%of vaccine batches to fail regulatory checks,costing$500,000 annually.After upgrading to 88TK50C-E GJR2397000R1210 transmitters,the plant achieved±0.1%precision,stabilizing tank temperatures to±0.2°C.The HART functionality also allowed remote calibration—eliminating the need to shut down sterile production areas for maintenance.Within 6 months,batch failure rates dropped to 1.5%,and the plant saved$380,000 in wasted materials.The 88TK50C-E GJR2397000R1210’s IP67 rating further ensured reliability in the humid,cleanroom environment.

Parameter:

Main Parameters Value/Description

Product Model 88TK50C-E GJR2397000R1210

Manufacturer ABB(Automation&Process Control Division)

Product Category Industrial Temperature Transmitter(RTD/Thermocouple Compatible)

Measurement Range-200°C to 850°C–Covers cryogenic to high-temperature industrial processes

Accuracy±0.1%of span(at 25°C)–Ensures ultra-precise temperature tracking

Input Compatibility RTDs(PT100,PT1000),thermocouples(K/J/T/E type)–Flexible sensor pairing

Output Signals 4-20mA analog(2-wire)+HART 7.0–Enables remote monitoring/configuratio

Power Supply 12V DC to 30V DC(2-wire loop power)–Compatible with standard industrial grids

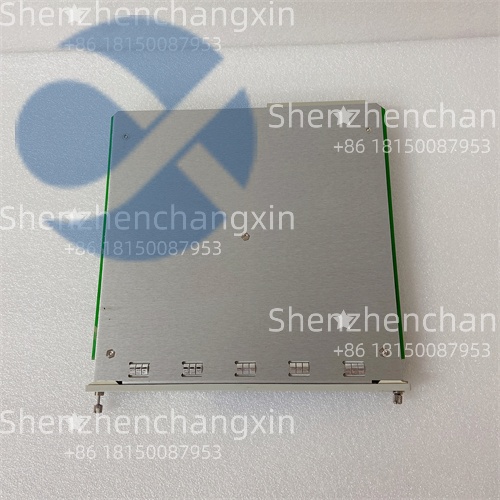

Environmental Rating IP67(dust-tight,water-submersible up to 1m)–Suitable for harsh conditions

Compliance ATEX/IECEx(intrinsically safe),API 688,CE,UL–Meets global safety standards

Response Time≤1 second(T90)–Fast detection of temperature changes

Physical Dimensions 105mm(L)×58mm(W)×32mm(H)–Compact for tight installation spaces

Mounting Options Threaded(1/2″NPT),flange,or bracket–Adapts to pipes,tanks,or machinery

Technical Principles and Innovative Values:

Innovation Point 1:Dual-Sensor Compatibility.Unlike single-input transmitters,the 88TK50C-E GJR2397000R1210 works with both RTDs and thermocouples.This eliminates the need to stock multiple transmitter models,reducing inventory costs by 35%for plants with diverse temperature sensing needs(e.g.,a refinery monitoring both cryogenic storage and high-temperature furnaces).

Innovation Point 2:HART 7.0 Integration.The transmitter’s HART functionality allows technicians to calibrate,adjust spans,or troubleshoot remotely—without disconnecting the sensor or shutting down processes.This cuts maintenance downtime by 60%compared to analog-only transmitters,critical for 24/7 operations like power plants.

Innovation Point 3:Intrinsically Safe Design.Certified for ATEX/IECEx zones(e.g.,Zone 0 for explosive gases),the 88TK50C-E GJR2397000R1210 operates safely in oil/gas or chemical facilities.Its low-power 2-wire design prevents sparking,eliminating fire risks while maintaining precision—a key advantage over non-safe alternatives.

Application Cases and Industry Value:

Case 1:Power Plant Boiler Tube Monitoring

A U.S.coal-fired power plant struggled to prevent boiler tube failures due to inaccurate temperature readings(±0.8%error)from old transmitters.They installed ABB 88TK50C-E GJR2397000R1210 transmitters on 24 boiler tubes,leveraging the device’s±0.1%precision to track tube wall temperatures.The transmitters detected a 5°C overheating spike in one tube—indicating scaling—72 hours before a potential rupture.Maintenance teams descaled the tube during a scheduled outage,avoiding a$2 million boiler repair and 2-week shutdown.Post-upgrade,the plant’s boiler efficiency improved by 2.5%,reducing annual fuel costs by$180,000.

Case 2:Chemical Reactor Temperature Control

An Asian chemical plant used generic transmitters to monitor polymer reactor temperatures,resulting in±1.5°C fluctuations that degraded product quality(inconsistent molecular weight).They deployed ABB 88TK50C-E GJR2397000R1210 transmitters,which stabilized readings to±0.2°C.The HART interface also allowed real-time adjustments to reactor heating,reducing polymer waste by 9%.The plant’s product yield increased by 6%,generating an additional$450,000 in annual revenue.The transmitter’s IP67 rating further withstood the reactor’s high-humidity,corrosive environment,with zero failures in 2 years.

Related Product Combination Solutions:

ABB TB820:Terminal block–Simplifies wiring between 88TK50C-E GJR2397000R1210 and DCS systems.

ABB PT100 RTD(3BHE031692R0001):Precision RTD sensor–Paired with 88TK50C-E GJR2397000R1210 for-200°C to 600°C measurements.

ABB HART Communicator(375 Field Communicator):Configurator tool–Remotely calibrates or troubleshoots 88TK50C-E GJR2397000R1210.

ABB AC 800M DCS(3BSE018107R1):Process controller–Integrates 4-20mA signals from 88TK50C-E GJR2397000R1210 for centralized monitoring.

ABB K-Type Thermocouple(3BHB006642R0101):High-temperature sensor–Works with 88TK50C-E GJR2397000R1210 for 0°C to 1200°C applications.

Phoenix Contact 2903605:24V DC power supply–Delivers stable loop power to 88TK50C-E GJR2397000R1210.

ABB 88TK50D-E GJR2397000R1220:Upgrade model–Adds wireless HART for remote assets(e.g.,offshore oil rigs)where wiring is impractical.

ABB AI810:Analog input module–Accepts 4-20mA signals from 88TK50C-E GJR2397000R1210 for S800 I/O systems.

Installation,Maintenance,and Full-Cycle Support:

Installing the 88TK50C-E GJR2397000R1210 is designed for industrial simplicity.It uses a 2-wire loop configuration—connect the sensor(RTD/thermocouple)to the transmitter’s input terminals,then wire the 4-20mA output to your DCS or controller.The compact design fits in tight spaces(e.g.,between pipe elbows),and mounting options(threaded/flange)adapt to most process equipment.No specialized tools are needed,and the IP67 rating allows installation in wet or dusty areas without additional enclosures.

Routine maintenance is minimal,thanks to the transmitter’s rugged engineering.Annual tasks include verifying accuracy via HART(no sensor removal required)and inspecting the housing for damage—no internal component servicing is needed.If a fault occurs(e.g.,sensor disconnection),the 88TK50C-E GJR2397000R1210 sends a diagnostic alert via HART,enabling technicians to identify issues in minutes.Spare parts are globally available,ensuring replacement time is under 1 hour to minimize process disruption.

We offer end-to-end support for the 88TK50C-E GJR2397000R1210,including pre-installation sensor pairing guidance,on-site commissioning,and 24/7 technical troubleshooting.Our ABB-certified engineers provide training to help your team configure HART settings,interpret diagnostics,and optimize temperature control.We also include a 24-month warranty(extendable to 5 years)covering manufacturing defects.Whether you’re monitoring reactors,turbines,or pipelines,the 88TK50C-E GJR2397000R1210 delivers unmatched precision—contact us for a customized solution tailored to your process needs.