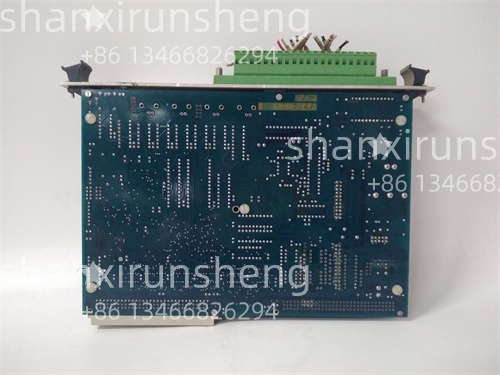

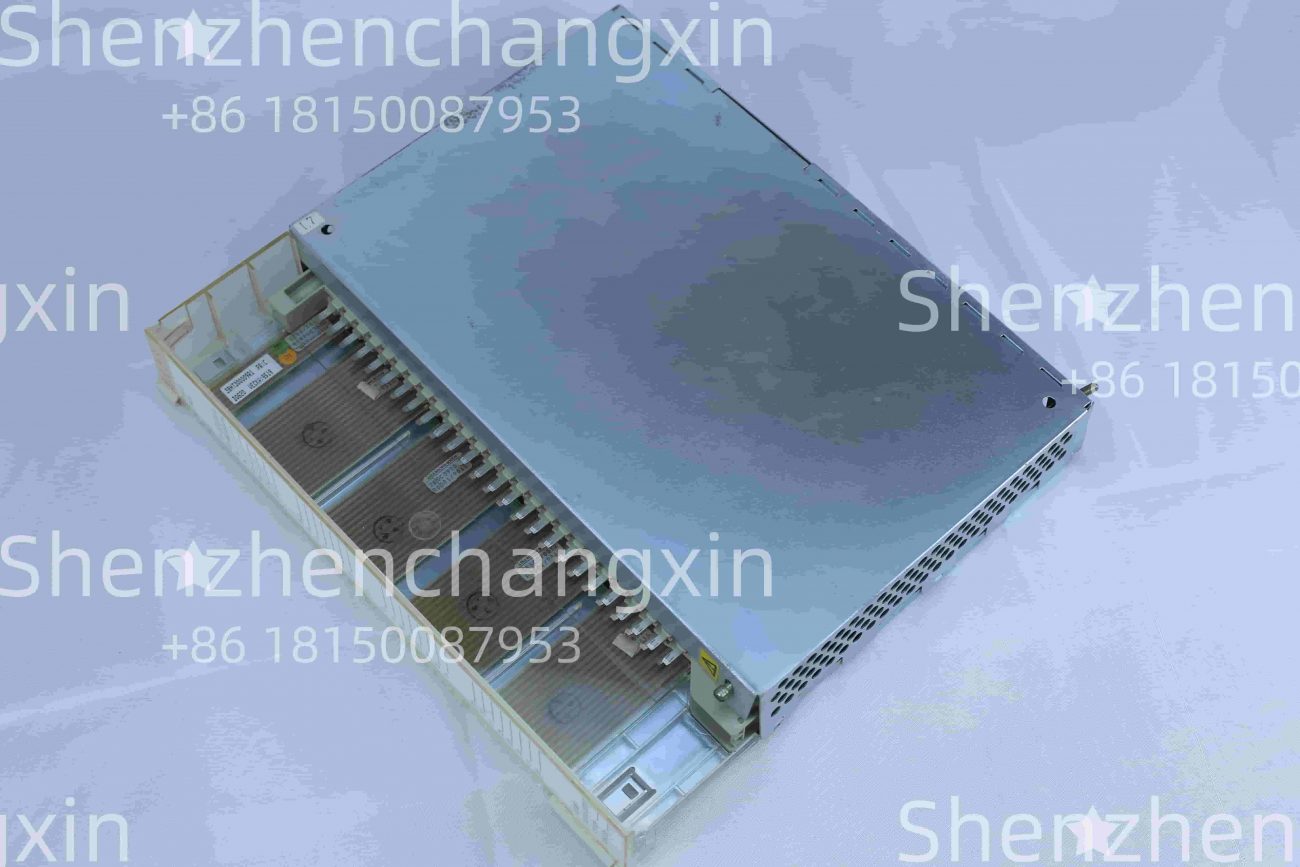

ABB Advant 31 07KT98 H31 Control Processor – Process Management Solution

Product Overview

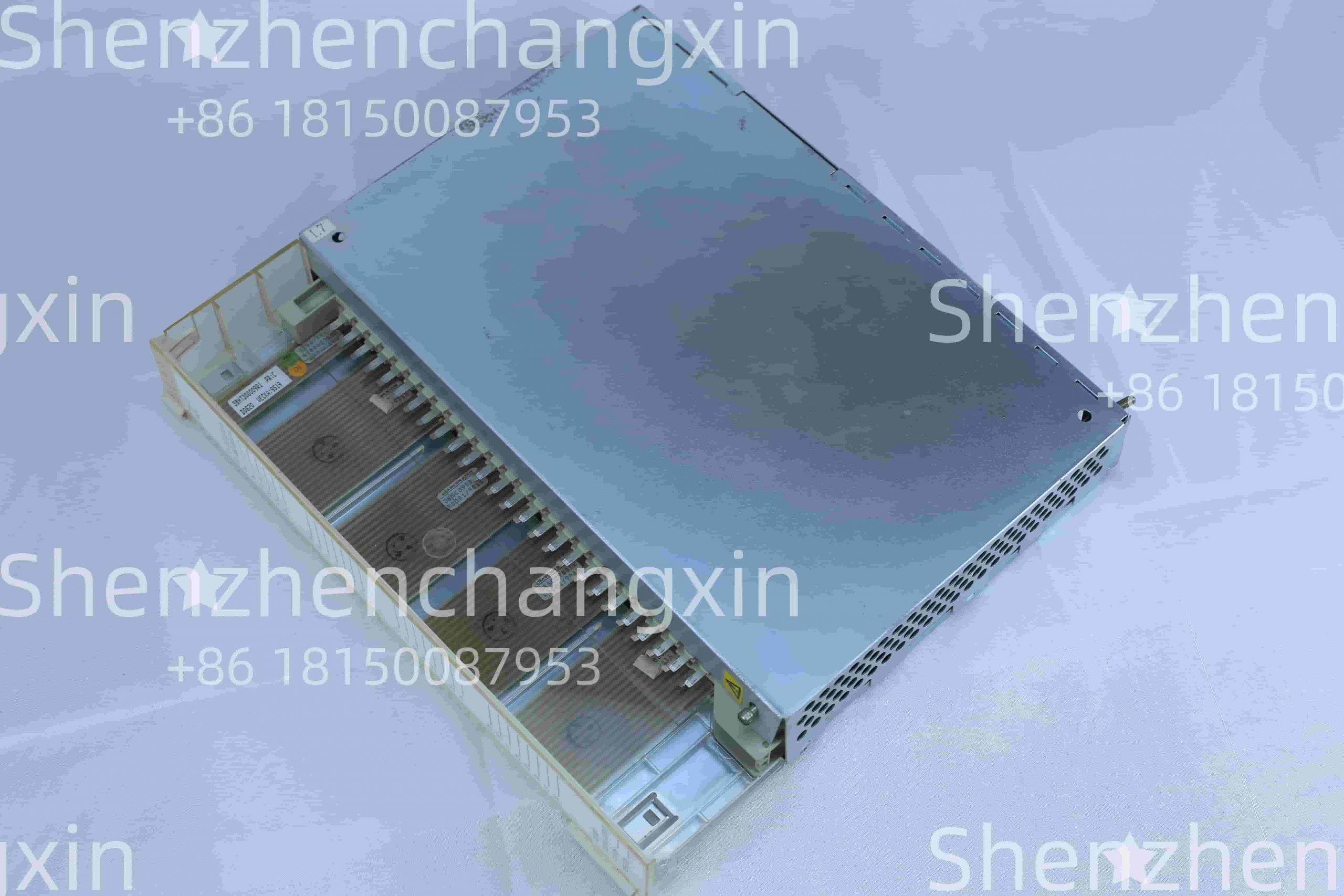

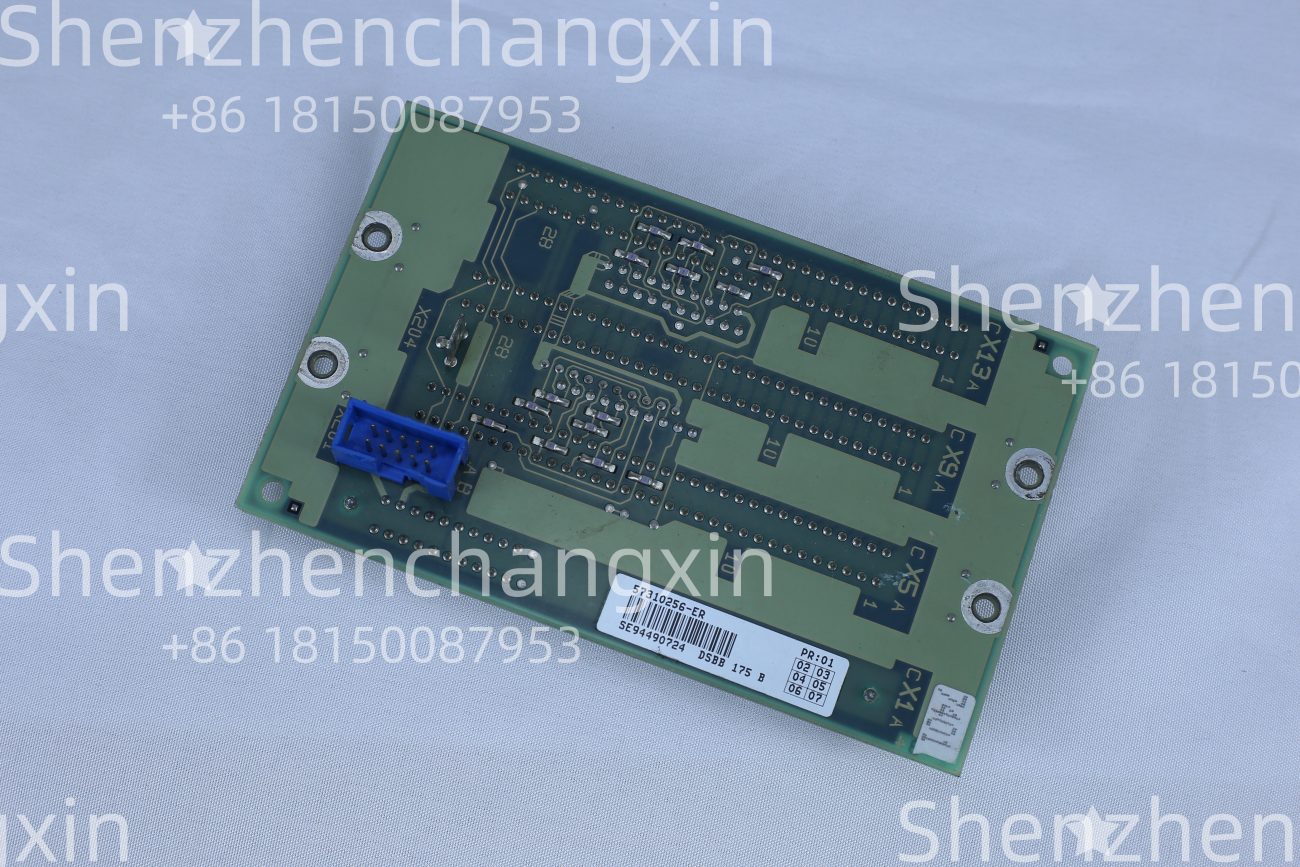

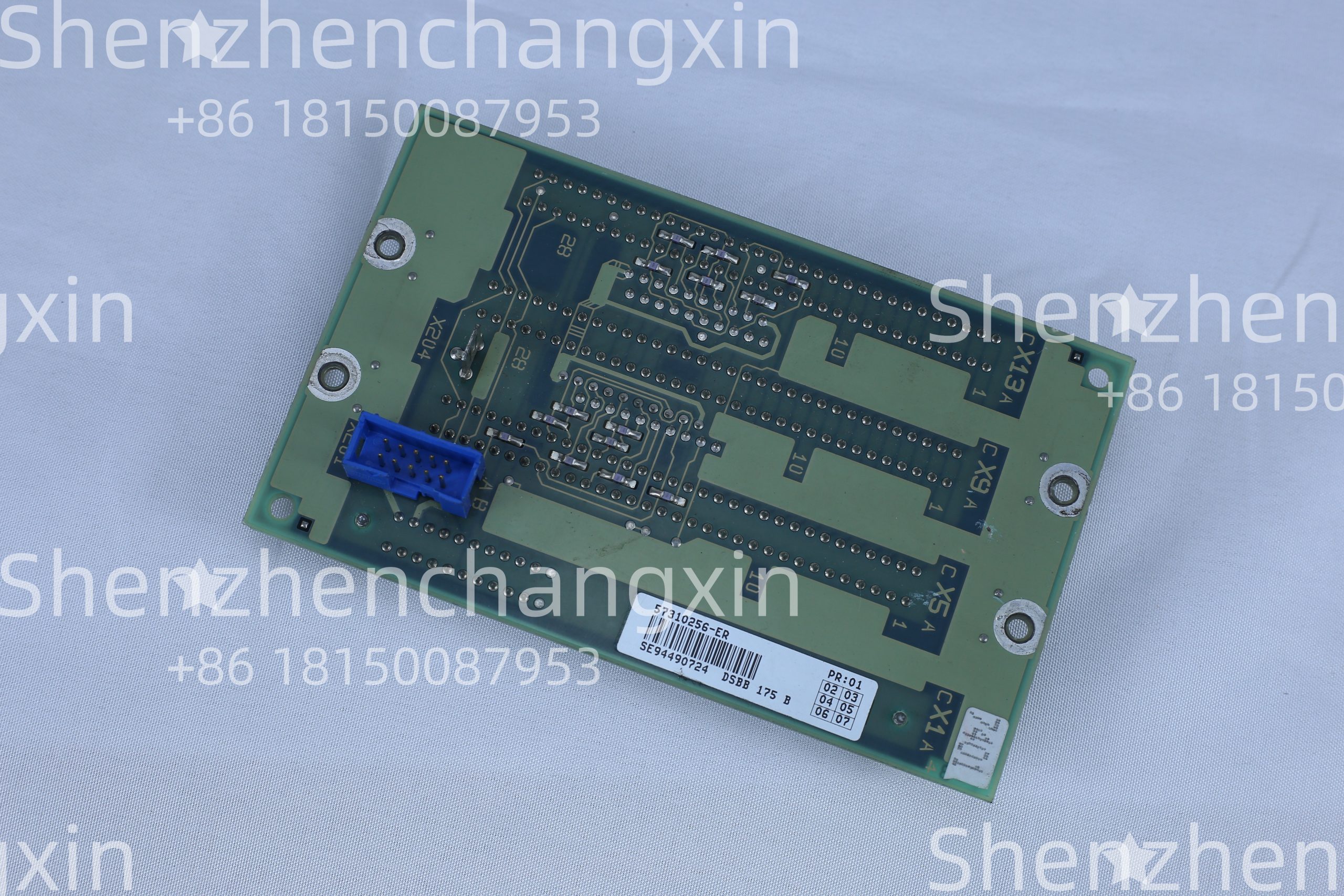

TheABB Advant 31 07KT98 H31represents a critical control processor module within ABB’s comprehensive Advant OCS(Open Control System)family,designed for industrial automation and process control applications.This robust controller forms the computational core of distributed control systems,delivering reliable performance in critical process industries including power generation,chemical processing,and oil and gas production.TheAdvant 31 07KT98 H31exemplifies ABB’s engineering excellence in control technology,providing a stable platform for complex control strategies while ensuring operational reliability in demanding industrial environments.

Engineered with industrial-grade components,theABB Advant 31 07KT98 H31features a powerful processor architecture capable of executing sophisticated control algorithms and managing extensive I/O configurations.The module integrates seamlessly within the Advant OCS architecture,communicating with other system components through high-speed networks while maintaining deterministic control performance.The07KT98 H31controller supports multiple programming languages including function block diagrams,sequential function charts,and structured text,offering flexibility for implementing various control strategies tailored to specific process requirements.

The implementation of theABB Advant 31 07KT98 H31in process control systems demonstrates ABB’s commitment to operational excellence and system reliability.The controller’s robust construction ensures stable operation in challenging industrial conditions characterized by temperature variations,electrical noise,and vibration.With features supporting comprehensive diagnostics,redundancy options,and flexible configuration,theAdvant 31 07KT98 H31provides a solid foundation for building scalable and maintainable control architectures across various industrial sectors.

Technical Specifications

Parameter Name

Parameter Value

Product Model

Advant 31 07KT98 H31

Manufacturer

ABB

Product Type

Process Controller Module

System Platform

Advant OCS(Open Control System)

Processor Type

32-bit RISC processor

Memory Capacity

16MB RAM(program and data)

Execution Speed

0.1ms for typical control algorithms

I/O Capacity

Up to 4096 I/O points

Communication

Advant Fieldbus,TCP/IP Ethernet

Programming

IEC 61131-3 standard languages

Power Supply

24VDC via backplane

Power Consumption

15W typical

Operating Temperature

0°C to 60°C

Storage Temperature

-40°C to 85°C

Relative Humidity

5%to 95%non-condensing

MTBF

>100,000 hours

Dimensions

200mm×150mm×100mm

Weight

2.5kg

Certifications

UL,cULus,CE,ATEX

Main Features and Advantages

High-performance processing:TheABB Advant 31 07KT98 H31delivers exceptional computational power through its advanced processor architecture,capable of handling complex control algorithms and extensive I/O configurations with deterministic performance.The controller’s fast execution speed ensures rapid response to process changes,while its substantial memory capacity supports sophisticated control strategies and data logging functions.TheAdvant 31 07KT98 H31multitasking capability allows simultaneous execution of multiple control loops,ensuring comprehensive process management across various operational scenarios.

Comprehensive system integration:Designed for seamless operation within the Advant OCS ecosystem,theABB Advant 31 07KT98 H31features native integration capabilities with ABB’s extensive range of I/O modules and field devices.The controller supports multiple communication protocols including Advant Fieldbus and standard Ethernet,enabling connectivity with various system components and enterprise networks.The modular architecture allows flexible system expansion,while the standardized programming environment simplifies application development and maintenance across the control system lifecycle.

Robust reliability features:Engineered for critical process applications,theABB Advant 31 07KT98 H31incorporates multiple reliability features including error-correcting memory,watchdog timers,and comprehensive self-diagnostics.The controller’s robust construction ensures reliable operation in industrial environments with electrical noise and temperature variations.Support for redundant configurations enhances system availability,while the non-volatile memory retains program and configuration data during power interruptions,ensuring continuous operation after power restoration.

Advanced diagnostic capabilities:TheABB Advant 31 07KT98 H31provides extensive diagnostic functions that monitor controller health,program execution,and communication status.Detailed fault information and event logging facilitate quick troubleshooting and preventive maintenance.The controller’s status indicators provide immediate visual feedback on operational condition,while the comprehensive alarm management system ensures timely response to abnormal process conditions.These diagnostic features contribute to reduced downtime and improved system maintainability.

Application Field

In power generation facilities,theABB Advant 31 07KT98 H31provides comprehensive control for turbine systems,boiler controls,and plant auxiliary equipment.The controller’s robust performance ensures reliable operation in critical power generation processes,while its communication capabilities enable integration with plant-wide monitoring systems.In nuclear power applications,theAdvant 31 07KT98 H31delivers the reliability and deterministic performance required for safety-related control functions.

Chemical and petrochemical industries utilize theABB Advant 31 07KT98 H31for process unit control,safety instrumented systems,and utility management.The controller’s ability to handle complex control strategies and extensive I/O configurations makes it suitable for large-scale continuous processes.In refinery applications,the07KT98 H31ensures precise control of distillation columns,reactor systems,and blending operations,contributing to product quality and operational efficiency.

Oil and gas production facilities employ theABB Advant 31 07KT98 H31for platform control systems,compressor station automation,and pipeline management.The controller’s rugged design withstands the challenging environments of offshore platforms and remote locations,while its communication capabilities support integration with supervisory systems and remote monitoring platforms.TheAdvant 31 07KT98 H31reliability ensures continuous operation in applications where downtime can result in significant production losses.

Related Products

ABB Advant 31 07KT99 H31:Enhanced version with additional memory

ABB Advant 31 07KT97 H31:Basic version for smaller applications

ABB S800 I/O:Remote I/O system for field connection

ABB COM600:Communication gateway for system integration

ABB Advant Controller 410:Higher performance controller

ABB AC 800M:Modern controller platform

ABB S100 I/O:Compact I/O system

ABB CI854:Communication interface module

ABB TU847:Terminal unit for signal conditioning

Installation and Maintenance

Pre-installation preparation:Before installing theABB Advant 31 07KT98 H31,verify compatibility with the existing Advant OCS infrastructure and ensure proper rack space availability.Confirm that environmental conditions meet specified requirements,particularly regarding temperature,humidity,and cleanliness.Have all necessary configuration tools and documentation available,and ensure proper electrostatic discharge precautions are observed during handling.

Maintenance recommendations:Regular maintenance of theABB Advant 31 07KT98 H31should include periodic verification of controller status through system diagnostics.Monitor operating temperatures and ensure adequate ventilation around the controller module.Keep firmware updated to the latest stable version and maintain current backups of application programs and configuration data.Document any configuration changes and maintain records of maintenance activities for future reference.

Product Guarantee

We guarantee that everyABB Advant 31 07KT98 H31controller module we supply is a genuine ABB component that meets all original manufacturer specifications.Our technical support team provides comprehensive assistance with system design,configuration,and troubleshooting.We stand behind the quality and performance of theAdvant 31 07KT98 H31controllers we provide,ensuring they deliver the reliable operation expected from ABB automation systems in demanding industrial applications.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

Product Overview

Product Overview

Product Overview

Product Overview