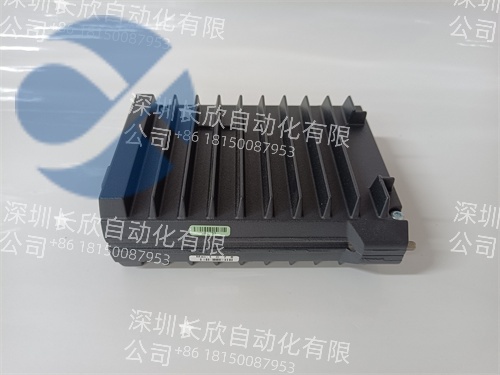

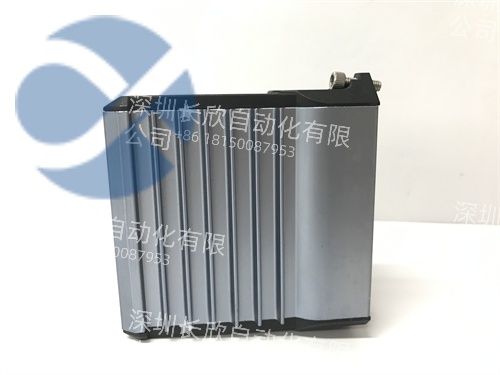

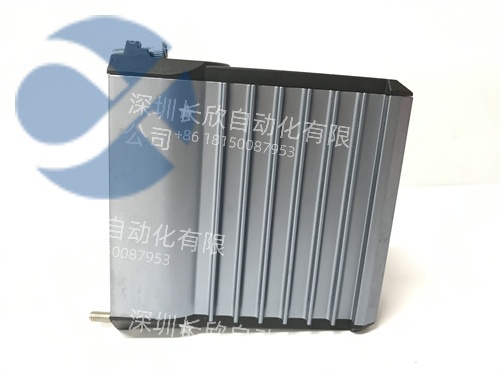

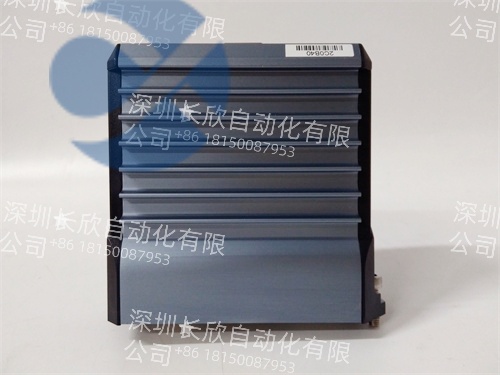

MOTOROLA FLN3524A

Product Overview

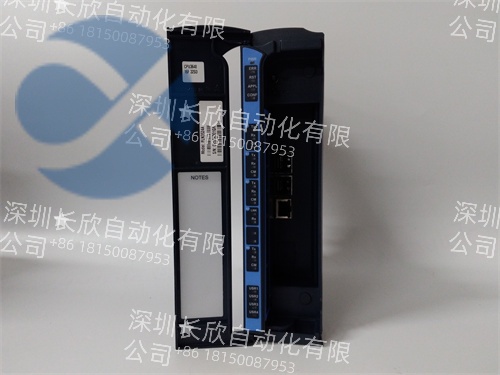

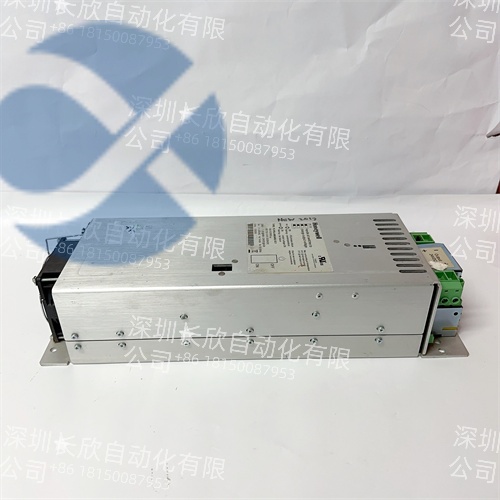

The MOTOROLA FLN3524A is a versatile industrial control component manufactured by Motorola,serving multiple functions including4-channel relay module,VMEbus single-board computer,andcommunication module.This multi-functional device is designed for various industrial automation applications,providing reliable control and communication capabilities in demanding industrial environments

.

TheMOTOROLA FLN3524Afeatures a sophisticated design with multiple interfaces and processing capabilities.As a relay module,it provides four independent channels for controlling different circuits or devices,while as a single-board computer,it offers powerful processing performance with integrated I/O interfaces

.

Engineered for industrial durability,theMOTOROLA FLN3524Aoperates within wide temperature ranges and features comprehensive protection mechanisms.Its modular architecture allows for flexible system integration and easy maintenance,ensuring reliable performance in various industrial applications

.

Technical Specifications

Parameter Name

Parameter Value

Product Model

MOTOROLA FLN3524A

Manufacturer

Motorola

Product Type

Multi-functional Industrial Module

Relay Module Specifications

Channels

4 independent relay channels

Single-Board Computer Specifications

Processor

PowerPC e500,833 MHz

Memory

512MB DDR333 ECC memory

Ethernet Ports

2×Gigabit Ethernet,1×10/100BaseTX

USB Interface

USB 2.0

Storage

Serial ATA controller

General Specifications

Operating Temperature

-40°C to+85°C

Voltage Range

3.3V~5V

Dimensions

20mm×15mm×2mm

Interface Types

SPI,I2C,RS232,RS485

Frequency Range

2.4GHz~2.4835GHz

Transmission Power

0dBm~20dBm

Main Features and Advantages

Multi-Channel Relay Functionality

TheMOTOROLA FLN3524Adelivers exceptional control performance through its four independent relay channels,enabling simultaneous control of multiple circuits or devices.This multi-channel design significantly enhances system flexibility and operational efficiency,allowing for complex control applications without requiring additional modules

.

High-Performance Processing

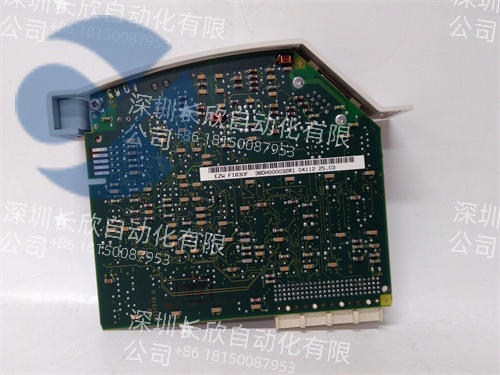

As a single-board computer,theMOTOROLA FLN3524Afeatures a powerful PowerPC e500 processor running at 833 MHz,supported by 512MB DDR333 ECC memory.This processing capability ensures rapid execution of control algorithms and real-time data processing,making it suitable for I/O and data-intensive applications

.

Comprehensive Communication Interfaces

TheMOTOROLA FLN3524Aprovides extensive connectivity options including two Gigabit Ethernet ports,one 10/100BaseTX port,USB 2.0,and serial ATA controllers.These interfaces support various industrial protocols and enable seamless integration with existing control systems and peripheral devices

.

VMEbus Compatibility

The module supports 2eSST VMEbus protocol,providing up to 320MB/s bus bandwidth while maintaining backward compatibility with VME64 and VME32 standards.This ensures compatibility with existing VMEbus platforms and facilitates system upgrades without requiring complete infrastructure replacement

.

Application Field

Industrial Automation Systems

TheMOTOROLA FLN3524Afinds extensive application in industrial automation systems,where it serves as both a control module and communication interface.In these environments,the module provides signal conversion,isolation,and relay control functions for various industrial processes,ensuring reliable operation and precise control

.

Power System Protection and Control

Power systems benefit from theMOTOROLA FLN3524A’s capabilities in monitoring and controlling generators,transformers,switchgear,and power distribution equipment.The module’s relay functions enable equipment protection,load management,and system optimization,ensuring stable power delivery and grid reliability

.

Safety Monitoring Systems

Safety monitoring systems utilize theMOTOROLA FLN3524Afor implementing alarm conditions and emergency shutdown functions.The module can detect specific alarm events and provide relay outputs for control actions or notifications,enhancing system safety and operational reliability

.

Defense and Aerospace Applications

TheMOTOROLA FLN3524Ais suitable for defense and aerospace applications,where its VMEbus compatibility and high-reliability design meet the stringent requirements of these industries.The module supports various operating systems including VxWorks,LynxOS,and Linux,providing flexibility for different application requirements

.

Related Products

MOTOROLA CPU3640:Central processor module compatible with FLN3524A for enhanced system performance

MOTOROLA MVME6100:VMEbus platform components for system integration and expansion

MOTOROLA FBM Series:Field bus modules for additional I/O capabilities and system expansion

MOTOROLA Communication Modules:Various communication interfaces for different industrial protocols and network requirements

MOTOROLA Power Supply Modules:Power distribution and management components for complete system solutions

Installation and Maintenance

Pre-Installation Preparation

Before installing theMOTOROLA FLN3524A,ensure that the control system environment meets specified temperature and humidity requirements.Verify that all wiring connections are properly terminated and that the power supply voltage matches the module specifications.The installation location should provide adequate clearance for wiring and maintenance access,with proper consideration given to heat dissipation requirements

.

Maintenance Recommendations

Establish a regular maintenance schedule for theMOTOROLA FLN3524Athat includes periodic inspection of module status indicators,verification of communication link integrity,and monitoring of diagnostic functions.Check all connections regularly for signs of corrosion or loose connections,and clean as necessary to ensure reliable operation.For critical applications,maintain spareMOTOROLA FLN3524Amodules to minimize downtime in case of hardware failure,and ensure that backup copies of configurations are maintained for quick system restoration

.

Product Guarantee

We guarantee that everyMOTOROLA FLN3524Amodule meets original manufacturer specifications and undergoes comprehensive testing before shipment.Each unit is backed by our technical support team with extensive experience in Motorola automation systems and industrial control applications.We provide a standard warranty covering all components and workmanship,with extended support options available for critical applications requiring enhanced service level agreements.Our commitment to quality ensures that you receive a fully functional module capable of reliable performance in the most demanding industrial environments,supported by complete documentation and configuration guidance to facilitate successful system integration and long-term operational reliability

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!