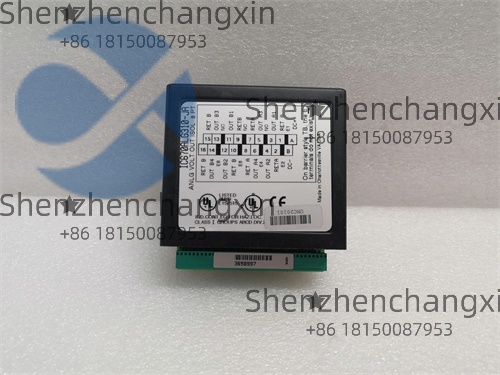

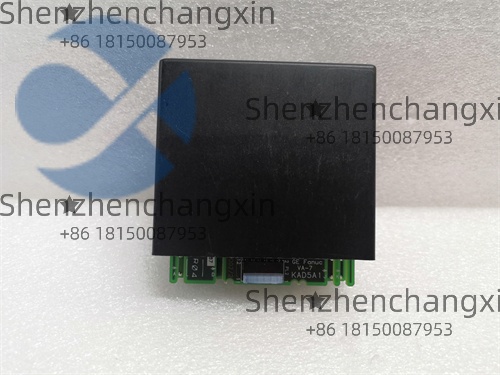

GE IC670MDL241J System Integration Solutions

Product Overview

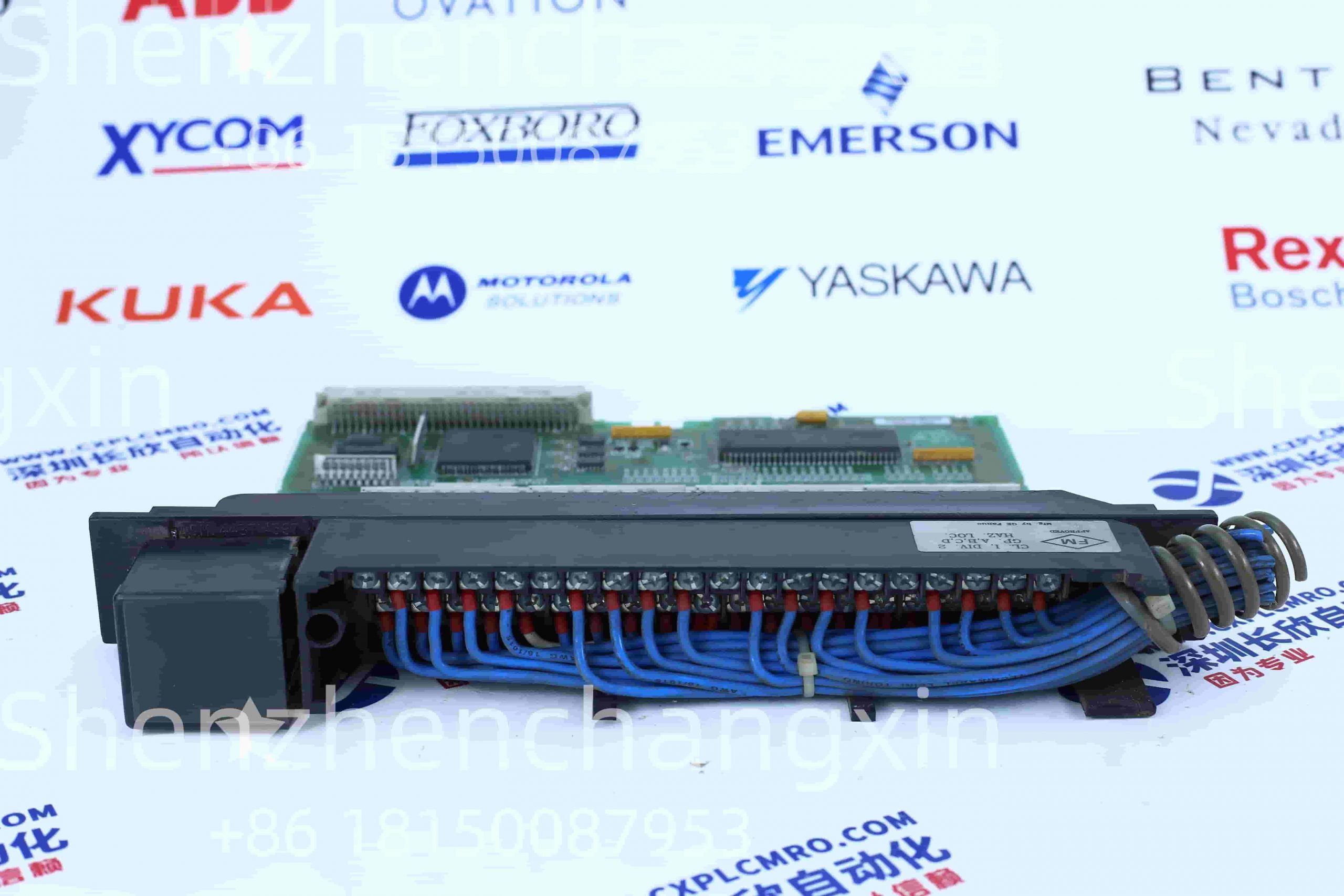

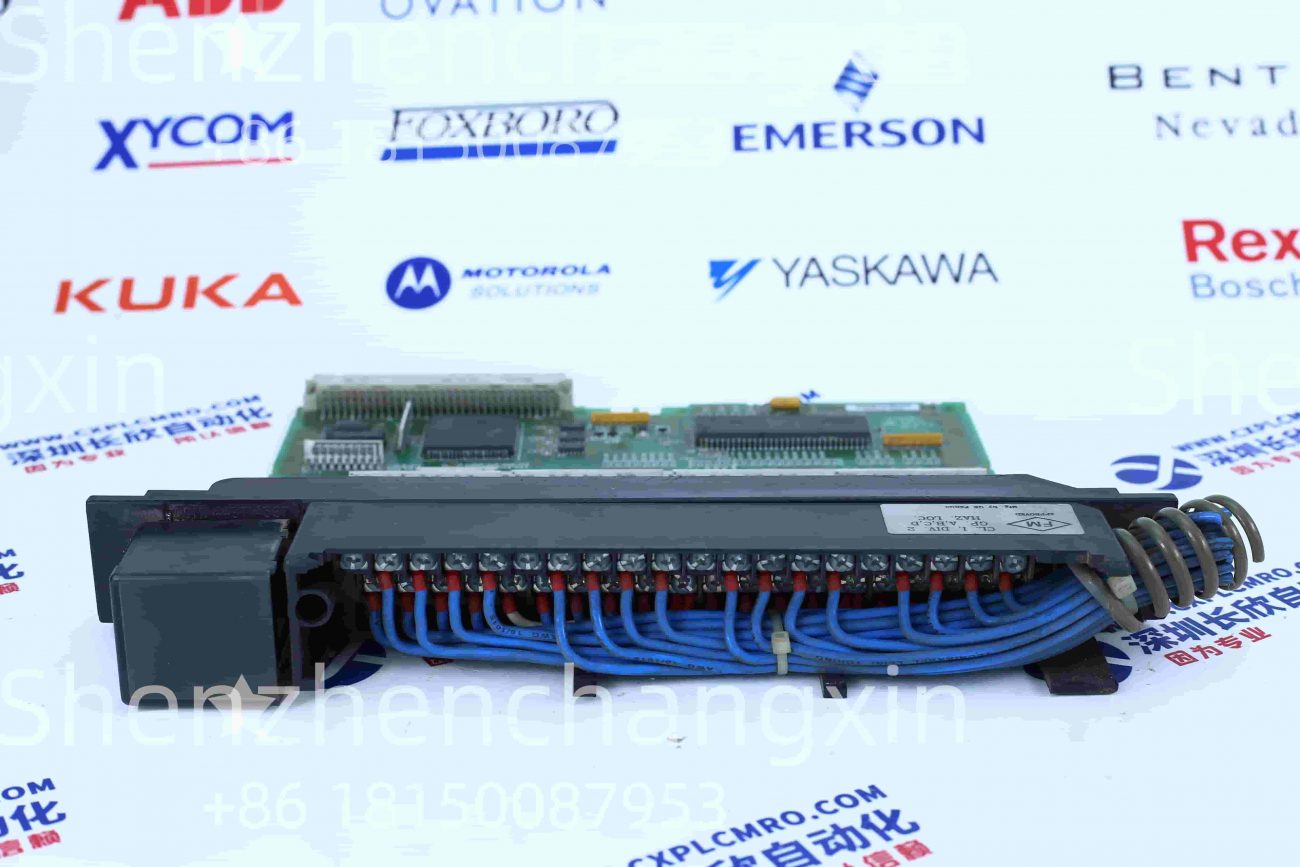

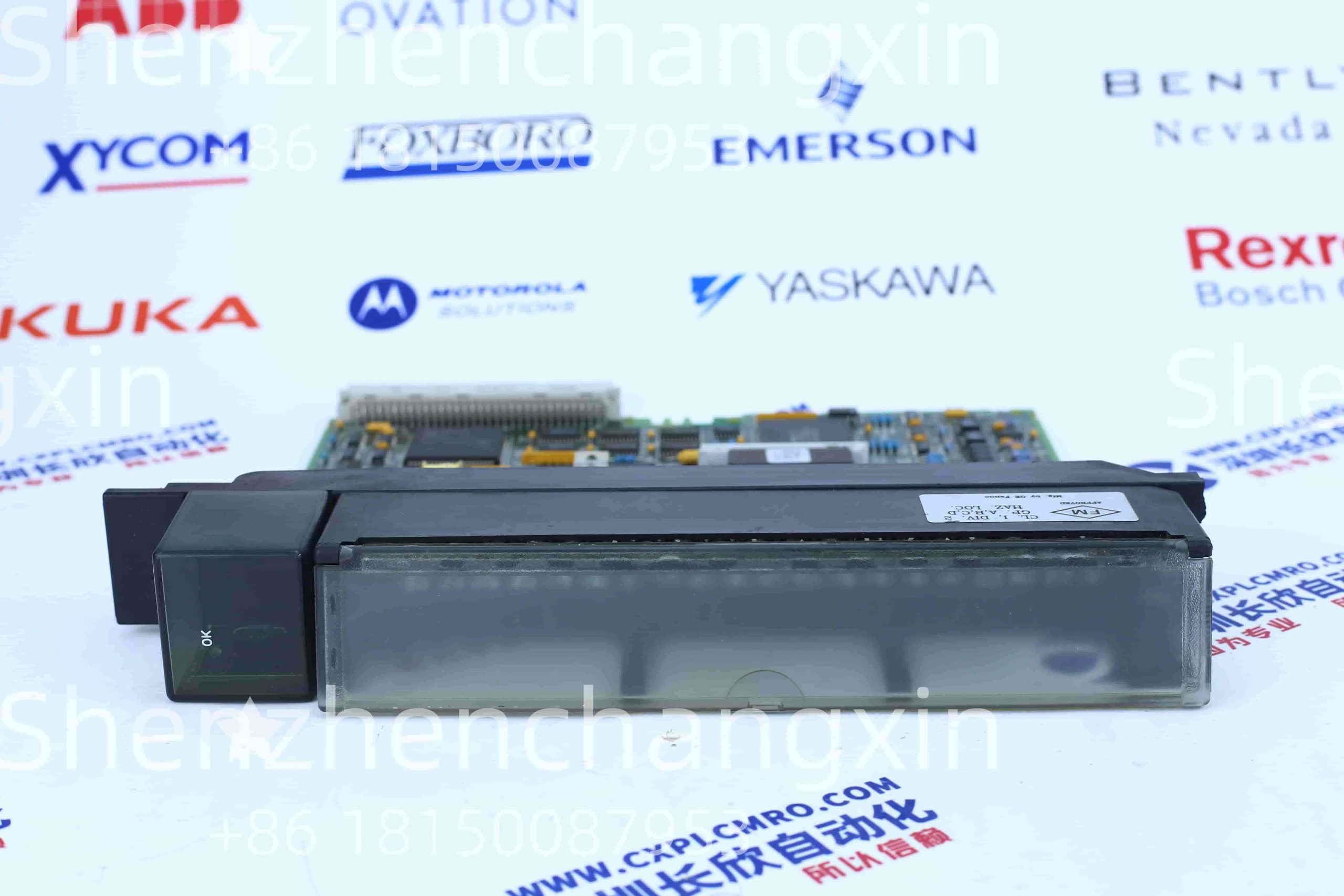

The GE IC670MDL241Jis a high-density digital input module designed for the Series 90-30 and Series 90-70 PLC systems,providing reliable acquisition of discrete signals from field devices in industrial automation applications.This 32-point sinking input module offers exceptional channel density and performance for monitoring contact closures,proximity switches,and other digital field devices.The IC670MDL241Jserves as a critical interface between field instrumentation and the control system,converting physical contact status into digital data for control logic and monitoring functions.With its robust design and advanced diagnostic capabilities,this input module ensures reliable operation in demanding industrial environments where signal integrity directly impacts system performance and safety.

In modern PLC architectures,the GE IC670MDL241Jtypically handles status monitoring for motors,valves,limit switches,and other field devices across various industrial processes.The module’s high channel density makes it particularly valuable in applications requiring extensive discrete input monitoring while conserving valuable rack space.The IC670MDL241Jdemonstrates excellent noise immunity and electrical isolation,maintaining signal accuracy even in electrically challenging environments with variable frequency drives and power distribution equipment.Its compatibility with the comprehensive Series 90 PLC system allows seamless integration into both new installations and existing system upgrades,providing a cost-effective solution for expanding digital input capabilities.

Technical Specifications

Parameter Name

Parameter Value

Product Model

IC670MDL241J

Manufacturer

GE Industrial Automation

Product Type

Digital Input Module

Number of Channels

32 points sinking inputs

Input Voltage

24V DC(19.2-30V DC)

On-State Voltage

15-30V DC

Off-State Voltage

0-5V DC

Input Current

7mA typical per point

Response Time

<10ms

Isolation

1500V AC channel-to-channel

Power Supply

Backplane powered

Power Consumption

850mA 5V DC

Operating Temperature

0°C to 60°C

Storage Temperature

-40°C to 85°C

Connection Type

Removable terminal block

Status Indicators

Per-channel LED indicators

Fault Detection

Open circuit monitoring

Certifications

UL,CSA,CE,cULus

Main Features and Advantages

High-density design:The GE IC670MDL241Jprovides 32 isolated input channels in a compact form factor,maximizing I/O density while minimizing control cabinet space requirements.Each channel features individual optical isolation(1500V AC)that prevents ground loops and ensures signal integrity in electrically noisy industrial environments.The module’s sinking input configuration simplifies wiring with field devices and supports both dry contact and solid-state sensor inputs,providing application flexibility without hardware modifications.

Diagnostic capabilities:Comprehensive per-channel LED status indicators provide immediate visual feedback of input status,facilitating quick troubleshooting and reducing mean time to repair.The IC670MDL241Jfeatures built-in diagnostics that monitor channel health and detect wiring faults,with open circuit detection alerting operators to disconnected field devices.The module’s hot-swappable design allows for replacement without system shutdown when used in redundant configurations,maximizing system availability.Non-volatile memory retains configuration parameters during power cycles,ensuring quick recovery after power interruptions.

Performance reliability:Advanced filtering algorithms eliminate contact bounce effects while maintaining fast response characteristics,ensuring accurate status reporting for critical interlock and safety functions.The module’s wide input voltage range(19.2-30V DC)accommodates voltage fluctuations commonly encountered in industrial power systems.Robust construction withstands vibration,temperature extremes,and electrical noise,ensuring long-term reliability with minimal maintenance requirements.

Application Field

The GE IC670MDL241Jfinds extensive application in industrial automation systems requiring reliable discrete signal acquisition.In manufacturing facilities,the module monitors equipment status across production lines,including motor run feedback,valve position indication,and safety interlock status.The IC670MDL241Jdemonstrates particular value in material handling systems,where it tracks conveyor status,pallet presence,and equipment readiness across extensive distribution centers.

Process industries utilize the GE IC670MDL241Jfor monitoring pump status,tank level switches,and safety system inputs in chemical processing and water treatment plants.The module’s high channel density makes it ideal for applications with extensive discrete monitoring requirements,such as packaging machinery with multiple sensor inputs and complex sequencing operations.Building automation systems employ the IC670MDL241Jfor monitoring HVAC equipment status,security system inputs,and energy management system controls,where its reliable performance supports continuous operation requirements.

Related Products

IC670MDL240|16-point digital input module

IC670MDR390|32-point digital output module

IC670ALG310|Analog input module

IC670CHS002|Genius bus controller

IC693CPU350|Series 90-30 processor

IC694|Series 90-70 system components

IC690ACC901|Communication accessories

Installation and Maintenance

Pre-installation preparation:Before installing the IC670MDL241J,verify field device compatibility and ensure proper voltage ratings match application requirements.Check terminal block connections and have appropriate wiring tools ready for installation.Plan channel assignments and document addressing for efficient system integration.

Maintenance recommendations:Perform regular verification of input status using the module’s LED indicators and system diagnostics.Monitor input voltage levels periodically to ensure they remain within specified ranges.Keep terminal connections clean and tight to maintain signal integrity.Maintain backup configurations of all parameter settings for quick recovery during module replacement.

Product Guarantee

We guarantee that every GE IC670MDL241Jdigital input module is a genuine GE Industrial Automation product manufactured to the highest industry standards.Our technical support team provides comprehensive assistance with system integration,configuration,and troubleshooting to ensure optimal performance in your specific application.All modules undergo rigorous testing to verify they meet original manufacturer specifications for reliability and performance in industrial environments.We stand behind the quality of our products with full technical support and commitment to customer satisfaction.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!