FOXBORO P0961BD-GW30B 20A DC Power Supply – CE, FM, ATEX Certified with Real-Time Voltage & Current Feedback

Description

The FOXBORO P0961BD-GW30B is a 20-ampere,24V DC redundant power supply module engineered for the FOXBORO I/A Series Distributed Control System(DCS),distinguished by its enhanced diagnostic firmware(GW30B revision)that enables real-time monitoring of output voltage,current load,and redundancy status directly through the DCS controller.

Unlike standard P0961BD units,the-GW30B suffix indicates a firmware-optimized variant designed for integration with advanced asset management platforms such as Emerson AMS Device Manager or Yokogawa PRM,allowing plant engineers to:

Track power supply health trends over time

Receive early warnings for capacitor aging or fan degradation

Monitor load balancing between redundant modules

Reduce unplanned downtime through predictive maintenance

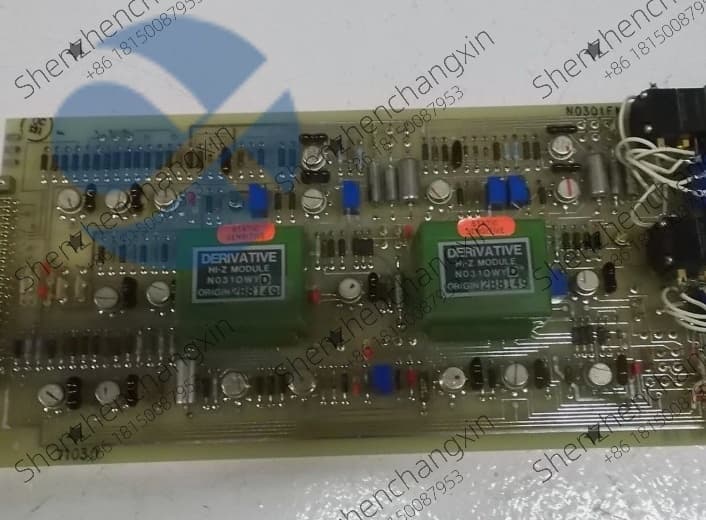

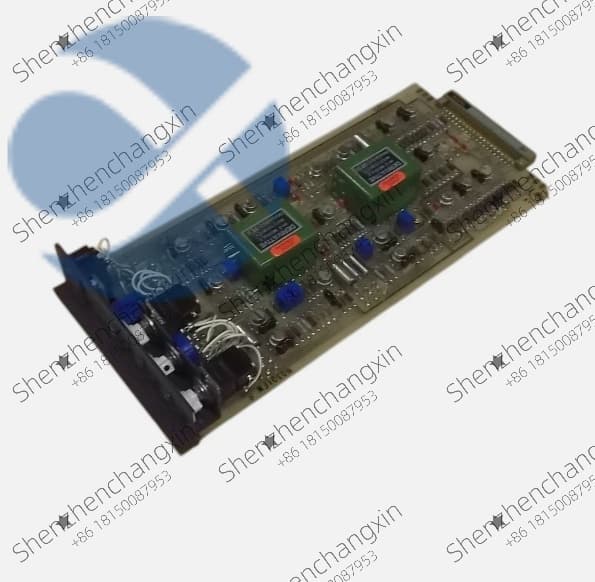

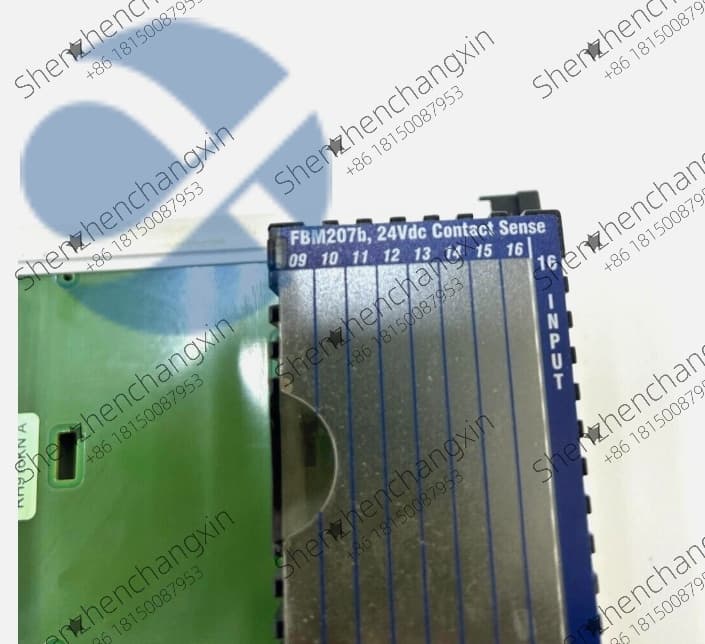

This module delivers<10 mV ripple,supports N+1 redundancy,and features hot-swappable installation.It powers medium-density racks populated with FBM207(AI),FBM223(HART AO),FBM208(DI),and similar smart I/O cards.With universal AC input(85–264V,47–63 Hz)and certifications including CE,FM Class I Div 2,ATEX Zone 2,it is approved for global deployment in hazardous areas.

Though now discontinued by Schneider Electric,the P0961BD-GW30B remains vital in digital-ready brownfield sites where power system visibility is key to operational reliability.

Application Scenarios

At a European pharmaceutical facility,regulatory compliance required full traceability of all critical loop diagnostics.Engineers deployed FOXBORO P0961BD-GW30B modules across reactor temperature and pressure I/O cabinets.The GW30B firmware enabled the DCS to log 24V rail stability(±0.2%)and PSU load profiles alongside process data.During a routine audit,a gradual rise in ripple on one module—detected via trend analysis—triggered a planned replacement before failure occurred.This proactive intervention avoided a potential batch loss valued at€1.2M.The P0961BD-GW30B thus became a cornerstone of their quality-by-design(QbD)infrastructure.

Parameter

Main Parameters Value/Description

Product Model FOXBORO P0961BD-GW30B

Manufacturer FOXBORO/Schneider Electric

Product Category Smart Redundant DC Power Supply with Diagnostics

Output Voltage 24 V DC±2%(non-adjustable)

Output Current 20 A continuous per module

Input Voltage 85–264 V AC,47–63 Hz(universal single-phase,auto-ranging)

Redundancy Mode N+1 redundancy with active synchronization(via GW30B firmware)

Output Ripple<10 mV peak-to-peak(at 20A,20 MHz bandwidth)

Diagnostic Features Real-time reporting of:

•Output voltage(±0.1V resolution)

•Load current(±0.5A resolution)

•AC/DC OK status

•Redundancy sync health

•Thermal warning flag

Communication Interface Integrated via I/A Series backplane—no external wiring;data accessible in Control Environment(CE)and System Management Station(SMS)

Protection Features Overcurrent foldback,short-circuit shutdown,thermal protection,surge suppression

Isolation Rating 3.0 kV AC input-to-output per IEC/EN 60950-1

Operating Temperature 0°C to+60°C

Mounting Slide-in module for I/A Series high-density I/O cage(hot-swappable)

Status Indicators“AC OK”,“DC OK”,and“SYNC”LEDs on front panel

Technical Principles and Innovative Values

Predictive Maintenance Ready:The GW30B firmware transforms the PSU from a passive component into an active health sensor.

Regulatory Alignment:Supports 21 CFR Part 11,GAMP 5,and IEC 62443 compliance through auditable power logs.

Seamless Integration:No additional hardware—diagnostics flow natively through the I/A Series architecture.

Brownfield Intelligence:Adds digital visibility to legacy systems without cabinet or controller upgrades.

Related Product Combination Solutions

FOXBORO FBM207/FBM223:Smart I/O cards benefiting from clean,monitored power

FOXBORO CP60/CP70:Controllers that ingest and display PSU diagnostic data

FOXBORO P0961BD(standard):Non-diagnostic version—not interchangeable if diagnostics are required

Schneider Electric P0961BE-GW31A:Successor variant(extremely rare)

Emerson AMS/Yokogawa PRM:Asset management platforms that can correlate PSU health with field device performance

Installation,Maintenance,and Lifecycle Support

Installation Notes:

Ensure I/O cage firmware supports GW30B diagnostic reporting(typically CP60/CP70 with OS v5.1+)

Verify“SYNC”LED illuminates in redundant configurations

Use 12 AWG stranded copper for AC input

Maintenance Strategy:

Enable power supply trending in DCS historian

Set alarms for:

•Ripple>12 mV(inferred from voltage noise)

•Load>18A sustained

•Redundancy sync loss

Replace units showing gradual voltage drift or increased thermal events

⚠️Critical Note:The FOXBORO P0961BD-GW30B is discontinued and firmware-specific.Standard P0961BD units cannot replicate its diagnostic capabilities.Due to its role in compliance-critical and predictive maintenance programs,it is a high-priority strategic spare.

We supply fully tested,burn-in validated FOXBORO P0961BD-GW30B units with:

Load test at 20A(24.0V±1.5%)

Ripple validation(<10 mVpp confirmed)

Diagnostic handshake verification with I/A Series simulator

12-month warranty and firmware compatibility assurance

Each unit is cleaned,labeled with traceable serial data,and packaged for ESD-safe storage.

Contact us today to secure your FOXBORO P0961BD-GW30B inventory—because in regulated and data-driven industries,knowing your power is healthy is just as important as having it at all.Don’t let obsolescence blind you to the heartbeat of your control system.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!