ALSTOM MCTI40N1AB0751G | Current Transformer

Product Overview

Product Overview

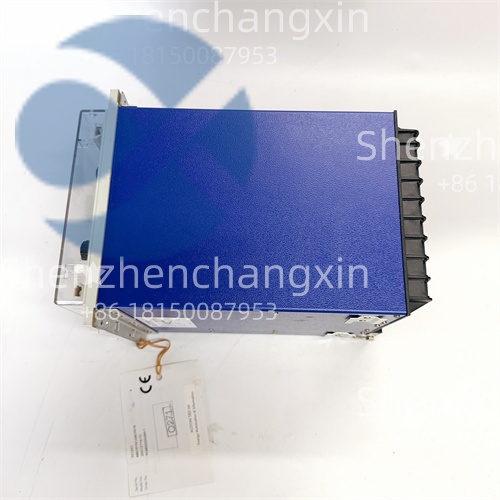

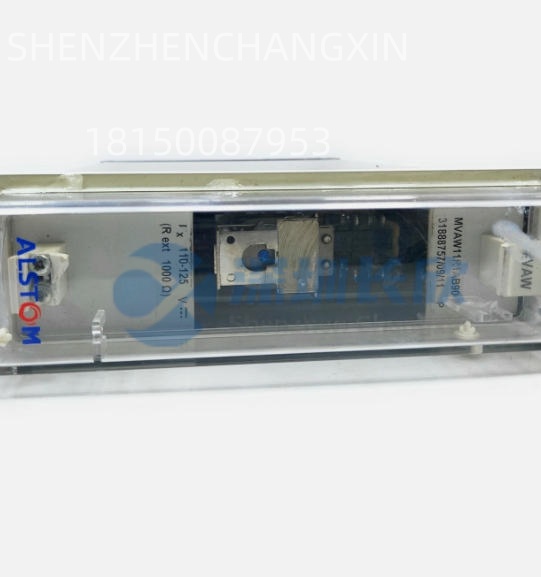

The ALSTOM MCTI40N1AB0751Gis a precision-engineered current transformer(CT)manufactured by ALSTOM(now part of GE Grid Solutions),designed for accurate current measurement and protection in medium-voltage electrical systems.This instrument transformer is a fundamental component in power distribution networks,serving to safely step down high primary currents to standardized,lower-level secondary currents suitable for connection to meters,protective relays,and other monitoring equipment.The MCTI40N1AB0751Gis engineered to provide reliable and precise performance in demanding industrial and utility applications,ensuring the safety and stability of electrical installations by enabling accurate monitoring and rapid fault detection.

As part of ALSTOM’s MCT series,the MCTI40N1AB0751Gfeatures a robust design typically configured as a ring-type(window-type)current transformer,allowing a primary conductor(busbar or cable)to pass directly through its center.This through-core design facilitates easy installation in switchgear,panel boards,and other electrical enclosures without the need to break the primary circuit.The transformer is constructed with high-quality magnetic core materials and precision windings to achieve its specified accuracy class,whether for metering(high accuracy at normal loads)or protection(accurate performance during fault conditions).Its insulation system is designed to withstand the electrical stresses of medium-voltage applications.

The ALSTOM MCTI40N1AB0751Gplays a critical role in electrical safety by providing galvanic isolation between the high-voltage primary circuit and the secondary measurement circuits.This isolation protects personnel and sensitive electronic equipment from high-voltage hazards.The dependable operation of this CT is crucial for functions ranging from accurate energy billing and power quality monitoring to the effective operation of protective relay systems that safeguard electrical equipment from damage due to overcurrent conditions.Its design complies with international standards,ensuring interoperability and reliable performance.

Technical Specifications

Parameter Name

Parameter Value

Product Model

MCTI40N1AB0751G

Manufacturer

ALSTOM(GE Grid Solutions)

Product Type

Current Transformer(CT)

Standard

IEC 61869-1,IEC 61869-2

Rated Primary Current(Ipr)

Specific value(e.g.,400A,800A,1200A)

Rated Secondary Current(Is)

1A or 5A

Accuracy Class

Metering:0.2,0.5,1.0;Protection:5P10,10P10

Rated Output(VA)

Specific burden(e.g.,10 VA,15 VA,30 VA)

Rated Frequency

50/60 Hz

Rated Insulation Level(kV)

Specific system voltage(e.g.,12kV,24kV)

Rated Short-Time Thermal Current(Ith)

Specific kA for 1s or 3s

Rated Dynamic Current(Idyn)

Specific kA(peak)

Accuracy Limit Factor(ALF)

10,15,20(for protection classes)

Window Diameter

Specific dimension in mm

Mounting

Fixed mounting within switchgear

Insulation

Resin cast or composite

Weight

Varies based on rating

Operating Temperature

-5°C to+40°C

Main Features and Advantages

The ALSTOM MCTI40N1AB0751Gdelivers exceptional value through its high accuracy and reliable performance.The transformer is designed to maintain its specified accuracy class across a wide range of operating conditions,which is critical for both revenue metering applications and precise operation of protective relays.The use of high-permeability core materials and optimized winding techniques minimizes errors(ratio and phase angle),ensuring that the secondary current is a true representation of the primary current.For protection classes,the high accuracy limit factor(ALF)ensures that the CT will saturate in a predictable manner,maintaining accuracy even during severe fault conditions to allow for selective relay operation.

Safety and durability are cornerstone features of this current transformer.The robust insulation system,often resin-cast,provides excellent dielectric strength and protection against environmental factors like moisture and contaminants,ensuring long-term stability and reliability.The design provides reliable galvanic isolation between the high-voltage primary and the low-voltage secondary circuits,which is a fundamental safety requirement.The compact and lightweight design,typical of resin-insulated CTs,simplifies handling and integration into switchgear assemblies,saving space and reducing overall weight.

The ALSTOM MCTI40N1AB0751Goffers application flexibility,with variants available for different primary currents,accuracy classes,and burdens.This allows it to be tailored to specific project requirements,whether for high-accuracy energy measurement or for demanding protection schemes requiring high fault withstand capabilities.Its compliance with international IEC standards guarantees interoperability with protection and metering equipment from major manufacturers worldwide.This combination of precision,safety,and flexibility makes the MCTI40N1AB0751Ga trusted component for engineers and system integrators.

Application Field

The ALSTOM MCTI40N1AB0751Gis widely deployed in medium-voltage switchgear for electrical distribution networks.In utility substations and industrial power plants,it is used for feeder and transformer protection,providing current signals to protective relays that safeguard equipment from overcurrent and short-circuit conditions.Its reliable performance during fault conditions is critical for the selective and fast operation of protection schemes,preventing equipment damage and minimizing outage times.

In commercial and industrial facilities,the MCTI40N1AB0751Gis commonly installed in main incoming switchboards and motor control centers for energy metering,demand monitoring,and as a sensor for feeder protection relays.Accurate current measurement is essential for utility billing,power factor correction,and managing energy efficiency.The transformer’s robust construction makes it suitable for the challenging electrical environments found in manufacturing plants,data centers,and large commercial buildings.

Furthermore,this current transformer is used in generation facilities for generator output monitoring and protection,as well as in large motor starter circuits.It is also applied in critical infrastructure such as water treatment plants,transportation systems,and mining operations,where reliable power monitoring and protection are crucial for operational continuity and safety.

Related Products

ALSTOM MCT Series CTs:Other current transformers in the same series with different current ratios or accuracy classes.

ALSTOM Voltage Transformers(VTs):Voltage transformers for complementary voltage measurement.

ALSTOM Protection Relays:such as the P14xor Dseries,which use signals from the MCTI40N1AB0751G.

ALSTOM Energy Meters:Energy meters that receive inputs from metering-class CTs.

ALSTOM Switchgear:The medium-voltage switchgear panels in which the CT is installed.

Installation and Maintenance

Pre-installation preparation:Before installing the ALSTOM MCTI40N1AB0751G,verify that the primary conductor(busbar or cable)size is compatible with the window opening of the current transformer.Ensure the installation site is clean,dry,and free of contaminants.Check the rated primary current,accuracy class,and burden to ensure they match the application requirements.Confirm that the system voltage does not exceed the transformer’s rated insulation level.The secondary circuit must be properly connected before energizing the primary conductor.

Maintenance recommendations:The MCTI40N1AB0751Grequires minimal maintenance due to its static design.Periodic visual inspections should check for any signs of physical damage,cracking of the resin insulation,or overheating.It is critical to ensure that the secondary circuit is never open-circuited when the primary conductor is energized,as this can produce dangerously high voltages and damage the transformer.The secondary terminals should be short-circuited if the connected device(meter,relay)is removed.Periodically check the tightness of secondary connections to ensure good electrical contact.Dielectric strength tests may be performed during major overhaul periods to verify insulation integrity.

Product Guarantee

We guarantee that the ALSTOM MCTI40N1AB0751Gis a genuine ALSTOM product,sourced through authorized channels to ensure it meets all original manufacturer specifications and performance standards.Each unit is subject to rigorous quality checks to confirm its electrical characteristics and mechanical integrity.We are committed to providing comprehensive technical support for product selection and application guidance.Our commitment ensures you receive a high-quality,reliable component backed by a standard warranty and our dedication to customer satisfaction.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!