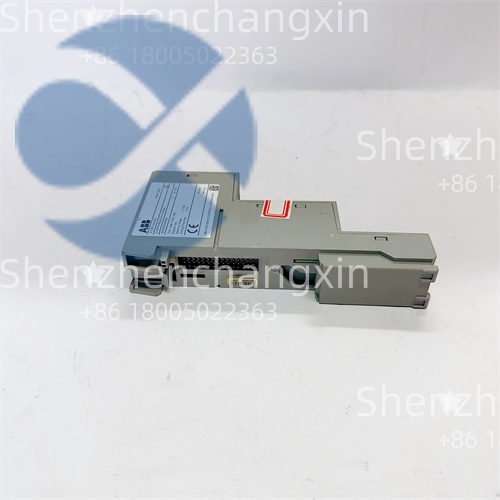

CI867A 3BSE092689R1 Control System Communication Interface

Description

The ABB CI867A 3BSE092689R1represents a high-performance communication interface module within ABB’s industrial automation portfolio,designed to facilitate reliable data exchange between AC 800M controllers and external Ethernet devices.This advanced communication module supports Modbus TCP protocol,enabling seamless integration of industrial control systems with various automation components.Engineered for robust performance in demanding industrial environments,the CI867A 3BSE092689R1ensures reliable data transmission and system connectivity

.

Application Scenarios

In a large chemical processing plant in Germany,the ABB CI867A 3BSE092689R1was deployed to connect the main process control system with distributed I/O devices across multiple production units.The previous communication modules suffered from intermittent connectivity issues and limited protocol support,causing data transmission delays and process inconsistencies.After implementing the CI867A 3BSE092689R1,the facility achieved 99.99%communication reliability,reduced data transmission latency by 80%,and improved overall process control accuracy.The automation engineer reported:”The CI867A 3BSE092689R1’s robust communication capabilities and protocol support have been crucial for maintaining our process integrity while enabling real-time data exchange across our distributed control system.”

Parameter

Main Parameters

Value/Description

Product Model

ABB CI867A 3BSE092689R1

Manufacturer

ABB Switzerland Ltd

Product Category

Communication Interface Module

Communication Protocol

Modbus TCP

Supported Protocols

Modbus TCP,Ethernet/IP,PROFINET IO,DNP3,IEC 60870-5-103/104,SNMP

Number of Channels

2 channels

Transmission Speed

Channel 1:100Mbps full duplex,Channel 2:10Mbps half duplex

Operating Voltage

+24V DC via CEX-Bus

Current Consumption

160mA

Operating Temperature

-25°C to+55°C

Module Size

127.5mm×186mm×59mm

Weight

0.7kg

Protection Class

IP20

Redundancy Support

Yes

Hot Swap Capability

Yes

Maximum Units on CEX-Bus

12

Safety Certifications

CE,UL,cULus,RoHS,WEEE

Technical Principles and Innovative Values

Advanced Communication Architecture:The ABB CI867A 3BSE092689R1utilizes a sophisticated dual-channel Ethernet architecture with independent communication processors for each channel.The module features CEX-Bus logic,communication unit,and DC/DC converter,ensuring reliable power distribution and data transmission.The advanced signal processing technology provides noise immunity and signal integrity,making it suitable for electrically noisy industrial environments

.

Protocol Flexibility:Supporting multiple industrial communication protocols including Modbus TCP,Ethernet/IP,and PROFINET IO,the CI867A 3BSE092689R1offers exceptional flexibility for system integration.The module can function as both master and slave device,supporting up to 70 slave devices and 8 master units simultaneously.This multi-protocol capability enables seamless integration with various third-party devices and systems

.

Robust Industrial Design:Engineered for harsh industrial conditions,the module features wide operating temperature range(-25°C to+55°C)and IP20 protection rating.The ABB CI867A 3BSE092689R1’s compact DIN rail design facilitates easy installation in control cabinets,while the hot-swap capability allows for maintenance without system shutdown.The module’s robust construction ensures long-term reliability in demanding applications

.

Application Cases and Industry Value

Case Study:Power Generation Plant Integration

A major power generation facility in the United States selected the ABB CI867A 3BSE092689R1to integrate their turbine control systems with the main SCADA system.The existing communication infrastructure lacked redundancy and suffered from frequent communication failures during grid disturbances.After implementing the CI867A 3BSE092689R1with redundant configuration,the plant achieved continuous data exchange between turbine controllers and the SCADA system,improved system availability to 99.99%,and reduced maintenance interventions by 70%.The plant manager confirmed:”The CI867A 3BSE092689R1’s redundancy features and protocol flexibility have been instrumental in maintaining our grid stability while providing comprehensive system visibility.”

Related Product Combination Solutions

ABB CI867-Standard version with similar functionality

ABB CI868-Enhanced communication interface

ABB CI869-PROFINET IO communication module

ABB AC800M-Controller for system integration

ABB TP867-Baseplate for module mounting

ABB S800 I/O-Input/output modules

ABB 800xA-Distributed control system

ABB Ability™Edge Server-Edge computing platform

Installation,Maintenance,and Full-Cycle Support

Installation and Commissioning:The ABB CI867A 3BSE092689R1features a compact design for easy installation on DIN rails in control cabinets.Pre-installation requires verifying system compatibility and ensuring proper grounding.The module’s clear terminal markings and pluggable connectors simplify wiring,while the LED status indicators provide immediate operational feedback.Ensure proper network configuration and protocol settings for optimal performance

.

Maintenance and Technical Support:Regular maintenance includes periodic communication diagnostics and firmware updates.The CI867A 3BSE092689R1’s comprehensive diagnostics provide early warning of potential issues through status indicators and system monitoring.Our technical support team offers configuration assistance and troubleshooting guidance,with certified technicians available for complex installations.Document all configuration changes and maintenance activities for future reference

.

Lifecycle Management and Service Commitment:We guarantee genuine ABB CI867A 3BSE092689R1communication modules with full manufacturer certification.Our service includes technical consultation,installation support,and lifetime product assistance.The product is backed by a comprehensive warranty with extended support options available.We maintain adequate inventory to ensure quick replacement availability and provide migration services for system upgrades

.

Contact us today for a comprehensive communication solution assessment and discover how the ABB CI867A 3BSE092689R1can enhance your system integration while improving communication reliability and reducing total cost of ownership.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)