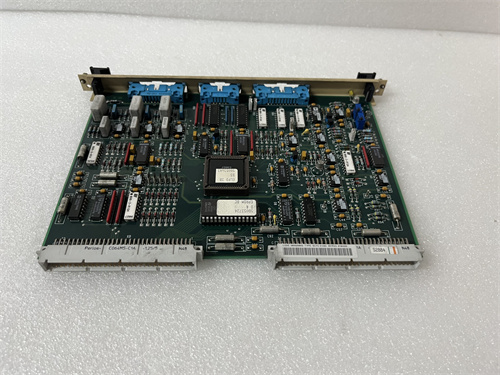

PP825A 3BSE042240R3 Automation Control Power

Product Overview

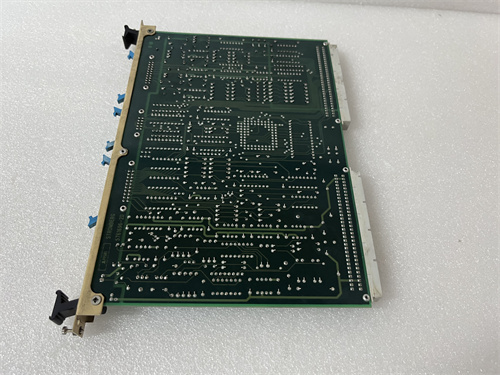

The ABB PP825A 3BSE042240R3represents a high-performance power supply solution within ABB’s comprehensive automation portfolio,designed as a reliable power source for industrial control systems and automation components.This advanced switching power supply delivers stable and clean DC power to various control system elements including PLCs,I/O modules,relays,and sensors in demanding industrial environments.The ABB PP825A 3BSE042240R3incorporates sophisticated power conversion technology and robust protection features that ensure continuous operation in challenging conditions,making it an essential component in process automation,manufacturing control systems,and infrastructure applications where power reliability is critical.

Engineered with efficiency and durability as core design principles,the ABB PP825A 3BSE042240R3features a wide input voltage range that accommodates various power grid conditions worldwide.The unit’s compact DIN rail mountable design optimizes control cabinet space utilization while providing sufficient power for medium-sized automation systems.With its high-efficiency rating and advanced thermal management,the ABB PP825A 3BSE042240R3minimizes energy consumption and heat generation,contributing to reduced operating costs and improved system reliability.The module’s robust construction includes conformal coated printed circuit boards and industrial-grade components that provide excellent resistance against humidity,dust,and electrical interference.

Technical Specifications

Parameter Name

Parameter Value

Product Model

ABB PP825A 3BSE042240R3

Manufacturer

ABB

Product Type

Switching Power Supply

Input Voltage Range

85-264V AC(100-370V DC)

Input Frequency

47-63Hz

Output Voltage

24V DC

Output Current

10A

Output Power

240W

Efficiency

>92%

Power Factor

>0.95

Ripple and Noise

<150mV

Line Regulation

±1%

Load Regulation

±1%

Overload Protection

105-150%

Overvoltage Protection

28-32V

Operating Temperature

-25°C to+70°C

Storage Temperature

-40°C to+85°C

Cooling Method

Convection cooling

Protection Class

IP20

Safety Standards

UL508,CSA C22.2

Main Features and Advantages

Advanced power conversion technology enables the ABB PP825A 3BSE042240R3to deliver exceptional efficiency exceeding 92%across the entire load range.The active power factor correction(PFC)circuitry ensures compliance with international harmonic current standards while minimizing reactive power consumption.The wide input voltage range from 85V to 264V AC allows operation in areas with unstable grid conditions,making the ABB PP825A 3BSE042240R3suitable for global applications with varying power quality requirements.This flexibility is particularly valuable in industrial settings where voltage fluctuations are common.

Comprehensive protection mechanisms ensure system safety and reliability.The ABB PP825A 3BSE042240R3incorporates multiple protective functions including overload protection,overvoltage protection,and short circuit protection with automatic recovery capabilities.These features prevent damage to connected equipment and ensure continuous operation even under abnormal conditions.The unit’s robust design includes reinforced insulation between input and output circuits,providing an extra layer of safety for both equipment and personnel.The ABB PP825A 3BSE042240R3also features thermal protection that automatically reduces output power or shuts down the unit in case of overtemperature conditions.

High power density design makes the ABB PP825A 3BSE042240R3particularly suitable for space-constrained applications.Despite its compact dimensions,the unit delivers 240W of reliable power,making efficient use of control cabinet space.The convection cooling design eliminates the need for fans,resulting in silent operation and higher reliability due to the absence of moving parts.The unit’s modular design allows for parallel operation for redundant configurations or higher power requirements,providing flexibility for various application scenarios.

Application Field

In industrial automation systems,the ABB PP825A 3BSE042240R3serves as a reliable power source for machine control panels and process control systems,providing stable power to AC 800M controllers,S800 I/O modules,and other automation components.Its 10A current capacity makes it suitable for powering multiple devices simultaneously,while the wide operating temperature range ensures reliable performance in harsh industrial environments.Manufacturing facilities utilizing the ABB PP825A 3BSE042240R3report improved system reliability and reduced downtime due to power-related issues.

Process industries including oil and gas,chemical,and power generation employ the ABB PP825A 3BSE042240R3for critical control system applications.The power supply’s robust design and comprehensive protection features make it suitable for safety instrumented systems where reliable power is essential for safe operation.In hazardous areas,the ABB PP825A 3BSE042240R3can be installed in non-hazardous locations while providing power to field devices through appropriate barriers and isolators,ensuring compliance with safety standards.

Related Products

ABB PP825B-Enhanced version with communication capability

ABB PP822A-Lower power version(120W)

ABB PP828A-Higher power version(480W)

ABB SD822-Digital input module for system integration

ABB SA823-Analog input module

ABB TU830-Terminal unit

ABB CI871-Communication interface

Installation and Maintenance

Pre-installation preparation:Before installing the ABB PP825A 3BSE042240R3,verify that the installation location provides adequate ventilation for heat dissipation and meets the temperature requirements specified in the technical specifications.Ensure the DIN rail is properly secured and check that the input voltage matches the local power supply characteristics.Prepare appropriate wiring tools and cables that meet the current carrying capacity requirements for the 10A output.

Maintenance recommendations:Regular maintenance of the ABB PP825A 3BSE042240R3should include visual inspection for dust accumulation and verification of terminal tightness.Monitor the unit’s status indicators during operation and verify output voltage stability periodically using calibrated measuring instruments.The convection cooling design requires keeping ventilation openings clear of obstructions.Document all maintenance activities for compliance and troubleshooting purposes.

Product Guarantee

We guarantee that every ABB PP825A 3BSE042240R3power supply unit is a genuine ABB product manufactured to the highest quality standards and subjected to comprehensive testing procedures.Our technical support team provides expert assistance with product selection,installation guidance,and troubleshooting support to ensure optimal performance in your specific application.The product is backed by a 36-month warranty covering manufacturing defects,supported by our commitment to customer satisfaction and reliable performance.We maintain adequate inventory to support urgent replacement needs and provide expert advice on system integration best practices.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

.jpg)