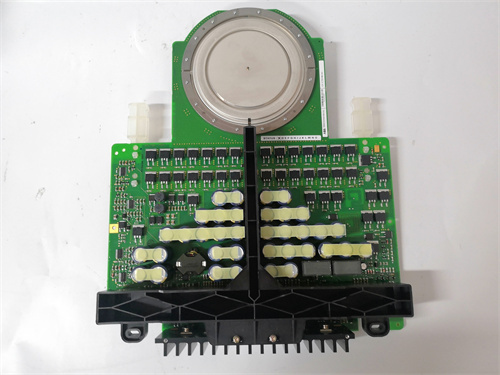

DSMC112 57360001-HC Automation Drive System

Description

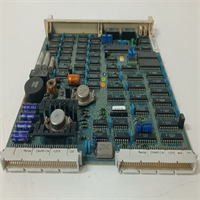

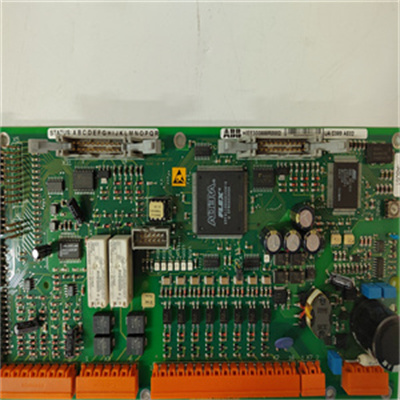

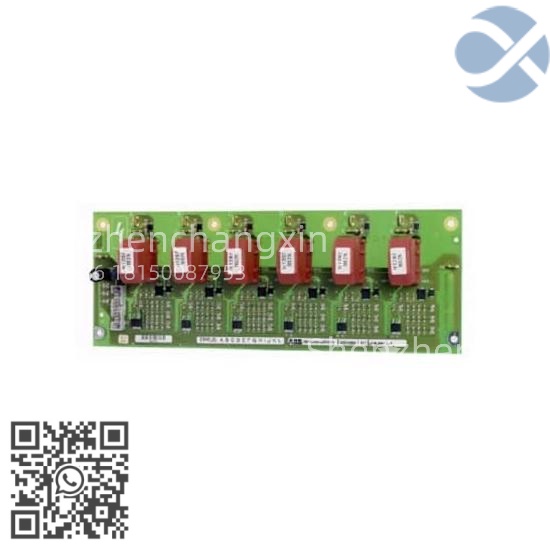

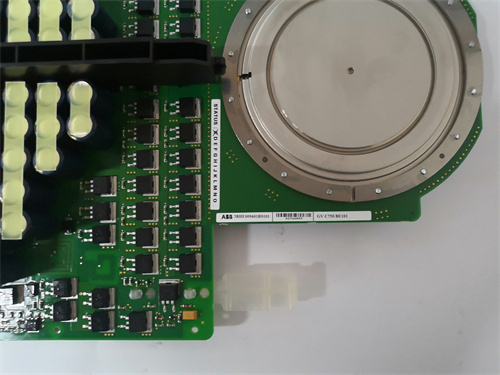

ABB DSMC112 57360001-HC:这是运动控制的”精密指挥官”!ABB公司设计的高性能伺服电机控制器,专为工业自动化和精密运动控制应用开发。采用先进的数字信号处理技术和智能控制算法,确保电机在高速高精度应用中的卓越性能。

控制方式:矢量控制/伺服控制

反馈接口:编码器/解析器

通信协议:EtherCAT,PROFINET

额定电流:10A

防护等级:IP20

Application Scenarios

In a high-speed packaging line running at 300 packages per minute,the ABB DSMC112 57360001-HCmotor controllers were deployed to synchronize 12 servo-driven filling and sealing stations.The previous motion control system suffered from positioning errors during rapid acceleration phases,causing product spillage and machine jams.After implementing ABB DSMC112 57360001-HCcontrollers with their advanced servo algorithms and high-resolution feedback processing,the line achieved positioning accuracy within±0.1mm,reduced product waste by 85%,and increased throughput by 22%.The controllers’robust design withstood the high-vibration environment,maintaining continuous operation for over 20,000 hours without failure.

Technical Specifications

Parameter

Value

Product Model

ABB DSMC112 57360001-HC

Manufacturer

ABB

Product Type

Servo Motor Controller

Control Method

Vector Control/Servo Control

Rated Current

10A continuous

Peak Current

30A(for 2 seconds)

Supply Voltage

24V DC±10%

Feedback Interface

Encoder(differential),Resolver

Communication

EtherCAT,PROFINET,CANopen

Control Cycle

62.5μs

Programming

IEC 61131-3 compliant

Memory

2MB Flash,512KB RAM

Digital I/O

8 inputs,4 outputs

Analog Inputs

2 channels±10V

Operating Temperature

0°C to+55°C

Storage Temperature

-40°C to+85°C

Protection Class

IP20

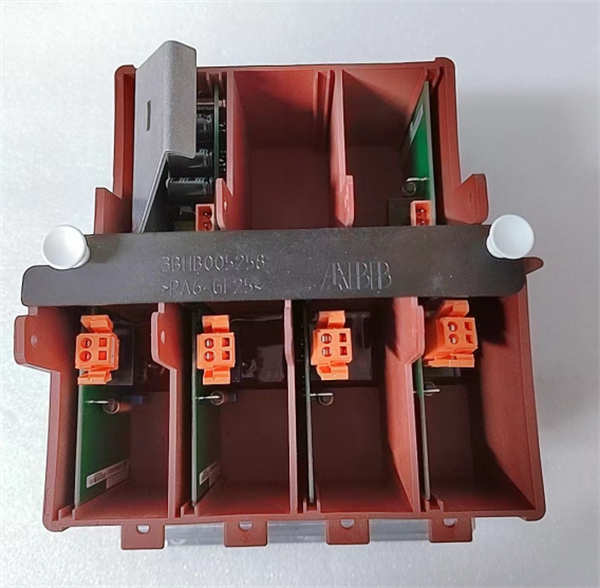

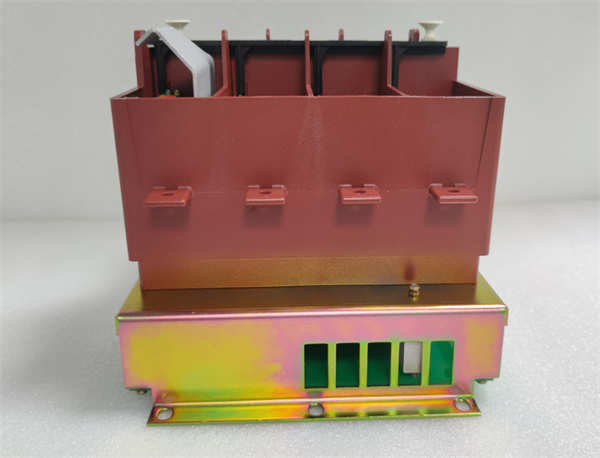

Mounting

DIN rail

Dimensions

150mm×100mm×75mm

Weight

0.8kg

Certifications

CE,UL,cULus

Technical Principles and Innovative Values

Advanced Servo Control Technology:The ABB DSMC112 57360001-HCutilizes high-precision current control with 16-bit resolution,achieving torque ripple of less than 0.5%.The adaptive filter technology automatically compensates for mechanical resonance,enabling stable operation at high speeds.This technology has demonstrated 50%better settling time compared to conventional servo drives in high-acceleration applications.

Intelligent Motion Planning:Featuring advanced trajectory generation algorithms,the controller supports electronic gearing,cam profiling,and position synchronization.The DSMC112 57360001-HC’s look-ahead function anticipates motion path changes,reducing vibration and improving contour accuracy by 30%in complex machining applications.

Robust Communication Architecture:With dual-port EtherCAT support,the controller enables daisy-chain connectivity with cycle times as low as 62.5μs.The ABB DSMC112 57360001-HCmaintains synchronization accuracy within 1μs across multiple axes,critical for coordinated motion applications.

Application Cases and Industry Value

Case Study 1:Robotics Assembly Cell

An automotive components manufacturer implemented ABB DSMC112 57360001-HCcontrollers in a robotic assembly cell handling 1,200 parts per hour.The controllers’precise torque control and backlash compensation reduced assembly insertion errors by 95%.The solution increased cell availability to 99.5%and reduced maintenance costs by 40%through predictive vibration monitoring.

Case Study 2:Printing Machinery

A packaging printer used ABB DSMC112 57360001-HCdrives for precise web tension control and print registration.The controllers’high-speed synchronization maintained registration accuracy within±0.05mm at speeds of 300 meters/minute.This precision reduced material waste by 60%and increased machine utilization by 25%.

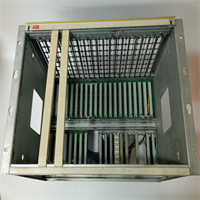

Related Product Combination Solutions

ABB DSMC113-Higher current version(20A)

ABB DSDI110-Digital input expansion module

ABB DSDO110-Digital output expansion module

ABB MSM Series-Compatible servo motors

ABB AC500-PLC controller for system integration

ABB CP600-HMI operator panel

ABB CI873-Communication interface module

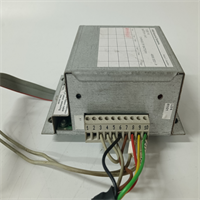

Installation and Maintenance

Installation Requirements:The ABB DSMC112 57360001-HCrequires proper DIN rail mounting with adequate clearance for heat dissipation.Motor cables should use shielded twisted-pair with proper grounding.Ensure encoder cables are routed separately from power cables to prevent noise interference.

Maintenance Protocol:Regular thermal imaging checks detect abnormal heating patterns.Firmware updates should be applied during planned maintenance windows.Backup configuration parameters before performing system modifications.

Technical Support:Our motion control specialists provide comprehensive services including system tuning,troubleshooting,and optimization.We offer 24/7 support for critical applications and maintain adequate spare parts inventory.

Contact us for technical consultation on your motion control requirements.Our ABB DSMC112 57360001-HCexperts deliver precision solutions for your most demanding automation applications.

We guarantee genuine ABB DSMC112 57360001-HC servo controllers.Our motion control specialists provide complete technical support from system design to commissioning,ensuring optimal performance for your precision automation systems.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!