Description

The IMDS003 is an intelligent motor diagnostic sensor independently developed by ABB,dedicated to real-time monitoring and predictive maintenance of low-voltage and medium-voltage electric motors.As a key component of industrial predictive maintenance systems,it integrates high-precision vibration acceleration sensors,temperature sensors,and intelligent signal processing chips,which can continuously collect motor operating data such as radial vibration,surface temperature,and running status,and identify potential faults(such as bearing wear,rotor imbalance,and stator winding aging)through built-in algorithms.Compliant with international standards such as IEC 60034-25 and ISO 10816,the sensor features small size,wireless/wired dual transmission modes,and strong environmental adaptability.It is widely used in motors of pumps,fans,conveyors,compressors,and other equipment in industries such as manufacturing,energy,water treatment,and mining,helping enterprises shift from”breakdown maintenance”to”predictive maintenance”,reducing unplanned downtime,and lowering maintenance costs.

Application Scenarios

A large water treatment plant in Shandong operates 120 sets of water pump motors(power range 15-75kW)for raw water intake,sedimentation,and disinfection processes.Previously,the plant adopted a regular maintenance mode(overhaul every 6 months),which had two major problems:on the one hand,some motors with hidden faults failed prematurely between overhauls,causing water supply interruptions—once a 75kW raw water pump motor bearing was damaged suddenly,resulting in a 4-hour water supply suspension for 200,000 residents and a direct economic loss of 300,000 RMB;on the other hand,some motors in good condition were disassembled and maintained unnecessarily,increasing maintenance costs by about 200,000 RMB per year.After installing ABB IMDS003 intelligent diagnostic sensors on all motors,the plant realized predictive maintenance of the motor system.The IMDS003 monitored the vibration and temperature of each motor in real time,and sent early warnings to the central control system when abnormal data was detected.In the past 18 months,the sensor successfully predicted 17 potential motor faults(including 9 bearing wear faults and 5 rotor imbalance faults),and the maintenance personnel handled them in advance during the scheduled downtime.No unplanned shutdowns caused by motor faults occurred,and unnecessary maintenance was reduced by 70%,saving 140,000 RMB in maintenance costs annually.This scenario fully demonstrates the important value of IMDS003 in improving the reliability of motor equipment and optimizing maintenance strategies.

Parameter

|Main Parameters|Value/Description|

|—————–|——————-|

|Product Model|IMDS003|

|Manufacturer|ABB Group(Switzerland)|

|Product Category|Intelligent Motor Diagnostic Sensor|

|Standards Compliance|IEC 60034-25,ISO 10816-3,IEEE 802.15.4|

|Monitoring Parameters|Vibration(acceleration,velocity,displacement),temperature|

|Vibration Measurement Range|Acceleration:0.1-100g;Velocity:0.1-100mm/s;Displacement:0.01-10mm|

|Vibration Measurement Accuracy|±2%of full scale|

|Temperature Measurement Range|-40℃~125℃|

|Temperature Measurement Accuracy|±0.5℃(-20℃~85℃),±1℃(beyond range)|

|Frequency Response Range|10Hz~10kHz|

|Data Transmission Mode|Wireless(ZigBee 3.0)/Wired(4-20mA analog output)|

|Wireless Communication Distance|Up to 100m(line of sight),30m(industrial environment)|

|Power Supply|DC 12-24V(wired mode);3.6V lithium battery(wireless mode,battery life≥5 years)|

|Sampling Frequency|1kHz(vibration),1Hz(temperature)|

|Fault Detection Functions|Bearing wear,rotor imbalance,misalignment,stator fault,resonance|

|Protection Level|IP67(sensor body),IP65(connector)|

|Installation Method|Magnetic adsorption/Bolt fixing|

|Dimensions(W×H×D)|45mm×45mm×30mm|

|Weight|85g(without battery),110g(with battery)|

|Special Functions|Data logging(10,000 sets of data),fault threshold customization,low battery alarm|

Technical Principles and Innovative Values

-Innovation Point 1:Multi-Parameter High-Precision Monitoring.The IMDS003 integrates a MEMS high-precision vibration sensor and a PT1000 temperature sensor,which can simultaneously collect three vibration parameters(acceleration,velocity,displacement)and motor surface temperature.The vibration measurement accuracy reaches±2%of the full scale,and the temperature measurement accuracy is±0.5℃in the normal temperature range,which is 30%higher than that of ordinary single-parameter sensors.This multi-dimensional data collection enables comprehensive evaluation of motor health status,avoiding missed detection caused by single-index monitoring.

-Innovation Point 2:Built-In Intelligent Fault Diagnosis Algorithm.The sensor is preloaded with ABB’s proprietary motor fault diagnosis algorithm,which can convert collected vibration and temperature data into characteristic values(such as peak-to-peak value,effective value,and frequency spectrum),and compare them with the built-in standard fault database to identify common motor faults(such as bearing inner ring/outer ring wear,rotor bar breakage,and coupling misalignment)with an accuracy rate of over 90%.Compared with traditional sensors that only output raw data,it reduces the dependence on professional data analysis personnel.

-Innovation Point 3:Dual Transmission and Long-Life Power Supply.The sensor supports ZigBee 3.0 wireless communication and 4-20mA wired transmission,adapting to different industrial scenarios—wireless mode is suitable for remote motors without wiring conditions,and wired mode is suitable for high-reliability requirements.In wireless mode,it uses a high-capacity lithium battery with low-power consumption design,and the battery life can reach more than 5 years under normal working conditions(sampling once every 10 seconds),which is 2-3 times that of ordinary wireless sensors,greatly reducing the workload of battery replacement.

-Innovation Point 4:Flexible Installation and Strong Environmental Adaptability.The IMDS003 adopts a magnetic adsorption and bolt fixing dual-mode installation design,which can be quickly installed on the motor end cover without disassembling the motor,and the installation time is less than 5 minutes per unit.The sensor body has an IP67 protection level,which can resist dust,water splashing,and oil pollution,and can work stably in harsh environments such as high temperature,high humidity,and vibration(vibration resistance up to 10g),adapting to the working conditions of most industrial motors.

Application Cases and Industry Value

Case 1:Water Treatment Plant Pump Motor Protection.The Shandong water treatment plant installed 120 IMDS003 sensors,which were connected to the plant’s central control system through ZigBee wireless gateways.In March 2025,the sensor of a 45kW sedimentation tank pump motor detected that the vibration velocity exceeded the set threshold(from the normal 2.5mm/s to 8.2mm/s)and the temperature rose by 15℃.The system immediately sent a fault early warning and identified it as a bearing wear fault through the built-in algorithm.Maintenance personnel disassembled the motor and found that the bearing inner ring was severely worn,and replaced it during the scheduled 2-hour downtime,avoiding an estimated 6-hour unplanned shutdown.In 18 months,the sensor helped the plant avoid 5 major motor fault shutdowns,saving more than 1.5 million RMB in direct economic losses.

Case 2:Automobile Parts Factory Conveyor Motor Monitoring.A Changchun automobile parts factory has 80 sets of conveyor motors(power 5-15kW)in its stamping and assembly workshops.The workshop environment is dusty and has high vibration,and ordinary sensors are prone to failure.After replacing with IMDS003 sensors,the IP67 protection level ensured stable operation,and the magnetic adsorption installation avoided damage to the motor surface.In July 2025,the sensor of a stamping workshop conveyor motor detected abnormal frequency components in the vibration spectrum,and the system judged it as a rotor imbalance fault.After inspection,it was found that the conveyor roller was eccentric due to wear.The fault was handled in advance,preventing the motor from being strained and reducing maintenance costs by 8,000 RMB.The factory’s motor maintenance cost dropped by 65%in one year,and the equipment operation rate increased from 92%to 98.5%.The maintenance director commented:”The IMDS003 not only allows us to find faults in advance,but also its stable performance in harsh environments saves us a lot of trouble in daily maintenance.”

Related Product Combination Solutions

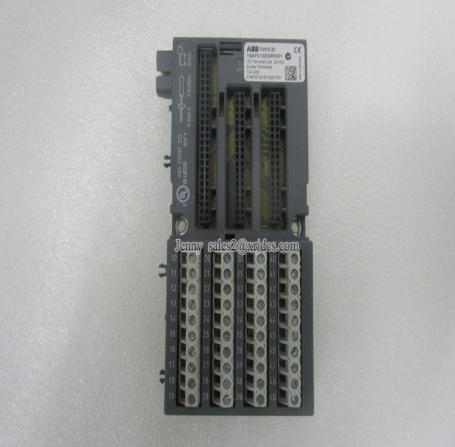

1.ABB AC500 PLC:A programmable logic controller that receives data from the IMDS003(via wired 4-20mA or wireless gateway),realizes local fault alarm and simple control.

2.ABB Ability™Condition Monitoring System:A cloud-based monitoring platform that collects data from multiple IMDS003 sensors,provides functions such as data analysis,fault diagnosis,and maintenance plan recommendation.

3.ABB ZigBee Wireless Gateway:A communication device that connects wireless IMDS003 sensors to the industrial Ethernet,realizing data aggregation and remote transmission.

4.ABB ACS880 Inverter:An industrial inverter that cooperates with the IMDS003,and can stop the motor in time when the sensor detects a fault,preventing fault expansion.

5.ABB CP635 HMI:A human-machine interface that displays real-time data and fault information of the IMDS003,enabling on-site personnel to monitor motor status intuitively.

6.SKF Explorer Bearing:A high-performance bearing that matches the IMDS003,and the sensor can monitor the bearing status in real time to maximize the service life of the bearing.

7.Microsoft Azure IoT Hub:A cloud platform that can be connected to the IMDS003 through the ABB Ability™platform,realizing large-scale data storage and AI-based advanced fault prediction.

Installation,Maintenance,and Full-Cycle Support

The IMDS003 supports magnetic adsorption and bolt fixing installation,suitable for the end cover or shell of various types of motors.Before installation,confirm the motor model and installation position(select the position with obvious vibration transmission,avoid the motor cooling fan area).For magnetic adsorption installation,clean the installation surface(remove rust and oil stains)and attach the sensor directly;for bolt fixing,drill aφ4mm hole on the motor surface and fix it with M4 bolts(torque:1.5N·m).For wired mode,connect the power supply(DC 12-24V)and signal line(4-20mA)to the terminal;for wireless mode,install the lithium battery and activate the sensor through the configuration software.After installation,use the calibration tool to verify the sensor’s measurement accuracy,and set the fault threshold according to the motor’s rated power and working conditions.

Routine maintenance of the IMDS003 focuses on status inspection and data verification.Monthly,check the sensor’s installation firmness(especially for magnetic adsorption installation)and the integrity of the cable(wired mode);for wireless sensors,check the battery level through the monitoring system.Quarterly,clean the sensor surface with a dry cloth to remove dust and oil stains,and avoid using water or chemical solvents.Semi-annually,perform a calibration test:compare the sensor’s measurement data with a standard vibration meter and thermometer,and adjust the calibration parameters if there is a deviation.Annual maintenance includes checking the wireless communication signal strength and updating the sensor’s firmware through the configuration software.In case of faults,no data output may be caused by power failure or battery exhaustion,and abnormal data may be caused by loose installation or sensor drift—resolve by checking the power supply,reinstalling the sensor,or recalibrating.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!