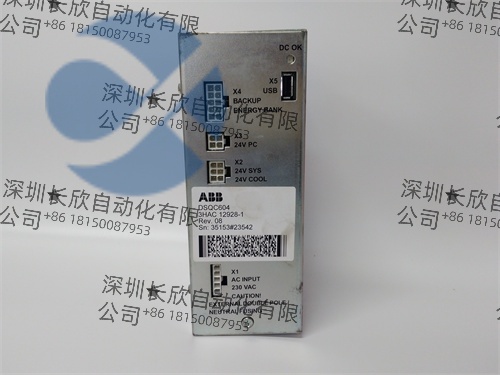

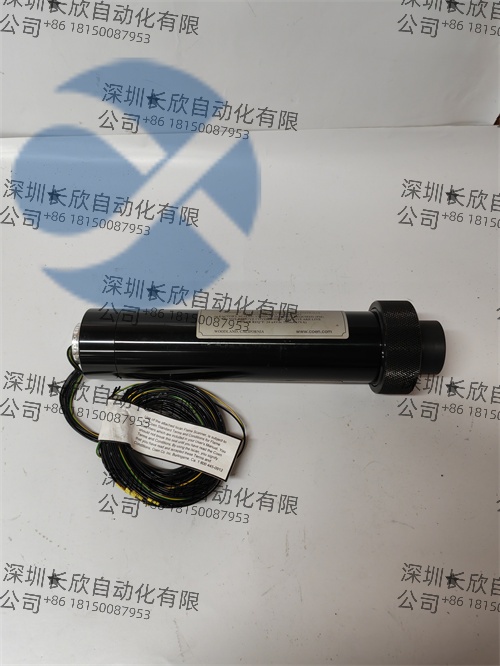

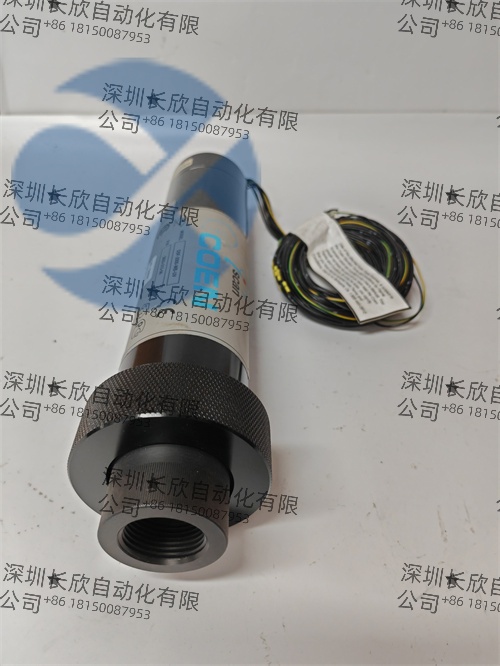

ABB DSMB-01C

Product Overview

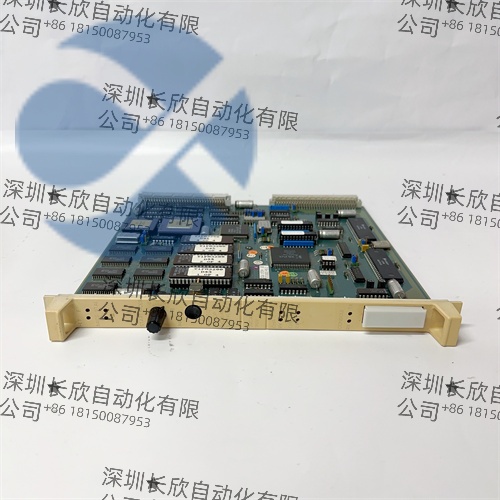

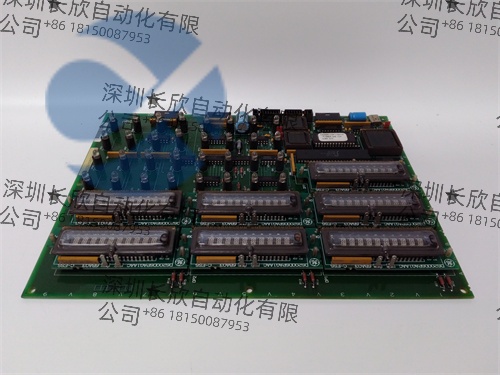

ABB DSMB-01C is a high-performance system communication board developed by ABB,specifically designed for seamless integration with ABB’s Advant OCS(Open Control System)—a pivotal platform in industrial automation,renowned for its stability in power generation,petrochemical,and heavy manufacturing sectors.As a core communication component in ABB’s Advant product lineup,this board serves as the”data bridge”between the Advant OCS controller and various industrial devices(such as I/O modules,remote sensors,actuators,and third-party control systems),enabling high-speed,reliable data transmission and protocol conversion for unified system operation.

In industries where real-time data sharing directly impacts process coordination and operational efficiency—such as power plant turbine control networks,petrochemical reactor data synchronization,and manufacturing line device interconnection—ABB DSMB-01C addresses the challenge of multi-device compatibility and data transmission stability in harsh environments.Its rugged industrial-grade design supports operation in extreme temperatures(-25℃~+70℃)and resists electromagnetic interference(EMI)from nearby high-voltage equipment or heavy machinery,ensuring consistent communication even in complex industrial settings.Additionally,the board adheres to ABB’s strict compatibility standards,enabling plug-and-play integration with existing Advant OCS installations—making it an ideal choice for upgrading legacy communication systems or replacing faulty network modules without costly reconfiguration.Whether used to connect distributed I/O modules in a refinery or synchronize data between multiple Advant OCS controllers in a power plant,ABB DSMB-01C delivers≤10ms data transmission latency and 99.99%communication availability,ensuring seamless system coordination and minimizing operational disruptions.

Technical Specifications

Parameter Name

Parameter Value

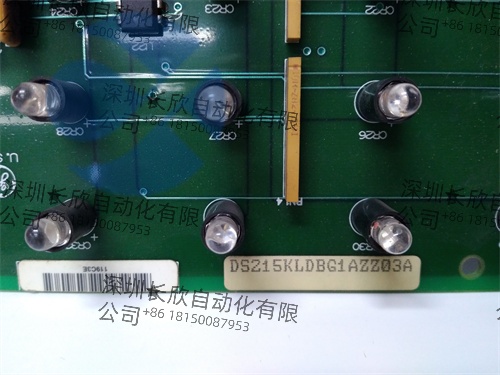

Product Model

ABB DSMB-01C

Manufacturer

ABB Group(Automation&Power Technologies Division)

Product Type

System Communication Board(for ABB Advant OCS Control System)

Compatible System

ABB Advant OCS;backward compatible with select Advant Master systems

Supported Protocols

Profibus DP,Modbus RTU,ABB Advant Fieldbus(AFB);optional Ethernet/IP via firmware upgrade

Communication Ports

2 x Profibus DP ports(RS485,12Mbps max);1 x Modbus RTU port(RS485,1Mbps max);1 x AFB port

Data Transmission Rate

Up to 12Mbps(Profibus DP);1Mbps(Modbus RTU);5Mbps(AFB)

Data Latency

≤10ms(end-to-end for Profibus DP);≤20ms(Modbus RTU)

Connection Capacity

Supports up to 32 Profibus DP slave devices;16 Modbus RTU slave devices

Isolation

500V DC galvanic isolation(port-port;port-ground)

Power Supply

24V DC(18V~30V wide voltage range;reverse polarity protection)

Power Consumption

≤8W(typical operating condition,all ports active)

Operating Temperature

-25℃~+70℃(continuous operation);-40℃~+85℃(storage)

Humidity Range

5%~95%RH(non-condensing,at 40℃)

Protection Rating

IP20(module-level);EMC compliance(EN 61000-6-2,EN 61000-6-4)

Physical Dimensions

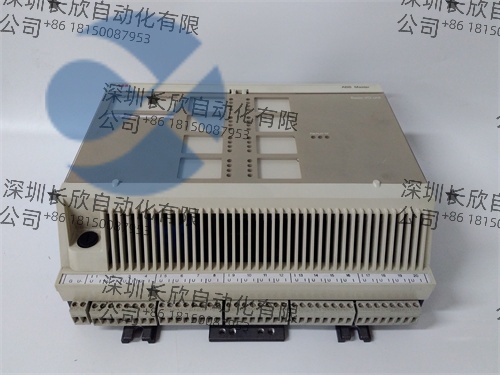

48mm(W)×100mm(H)×145mm(D)(standard 3U DIN rail form factor)

Mounting Method

35mm standard DIN rail mounting(compliant with EN 60715)

Certifications

CE,UL 508,ATEX(Ex II 3G Ex nA IIC T4 Ga),IEC 61131-3,RoHS

Diagnostic Features

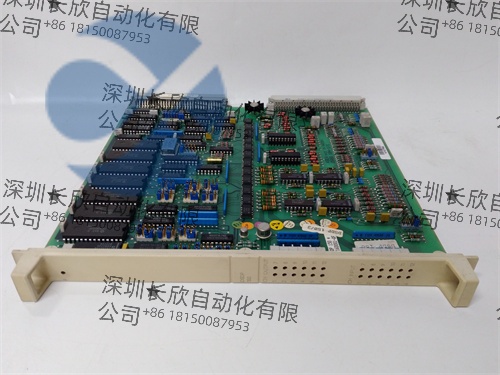

On-board LED indicators(power,port status,fault detection);cyclic redundancy check(CRC)for data integrity

Main Features and Advantages

Multi-Protocol Support for Versatile Connectivity:ABB DSMB-01C supports Profibus DP,Modbus RTU,and ABB Advant Fieldbus(AFB),enabling seamless integration with diverse industrial devices.A petrochemical refinery in Texas used the board to connect 28 Profibus DP-based flow sensors,12 Modbus RTU control valves,and 8 ABB AFB I/O modules to the Advant OCS system—eliminating the need for 3 separate communication modules and reducing cabinet space by 40%.This multi-protocol capability also simplified system expansion,as new devices could be added without protocol adapters.

High-Speed Low-Latency Data Transmission:With up to 12Mbps transmission rate(Profibus DP)and≤10ms latency,the board ensures real-time data synchronization for time-critical processes.A gas-fired power plant in Germany deployed ABB DSMB-01C to connect turbine vibration sensors to the Advant OCS controller;the fast data transfer allowed the system to detect vibration anomalies in 8ms,triggering protective actions to prevent turbine damage—avoiding an estimated$500,000 in repair costs.In contrast,a generic communication board with 50ms latency failed to detect a similar anomaly in time,leading to a 2-hour turbine shutdown.

Rugged Design for Harsh Environments:Rated for-25℃~+70℃operation and strict EMC compliance,ABB DSMB-01C performs reliably in extreme conditions.A steel mill in Russia installed the board in a hot rolling mill control cabinet(ambient temperatures up to 68℃);the module operated continuously for 32 months without communication interruptions,while a commercial-grade communication board failed every 10 months due to heat-induced component degradation.Its EMI resistance also ensures stable data transmission near high-power motors,preventing data corruption that could cause process errors.

Data Integrity Protection via CRC:The board’s cyclic redundancy check(CRC)feature verifies data integrity during transmission,reducing error rates to<0.001%.A nuclear power plant in France used ABB DSMB-01C to transmit reactor coolant temperature data;the CRC function detected and corrected 3 data corruption events in 24 months,ensuring the Advant OCS system received accurate temperature readings—critical for maintaining nuclear safety compliance.Without CRC,these errors could have led to incorrect control actions,risking reactor overheating.

Application Field

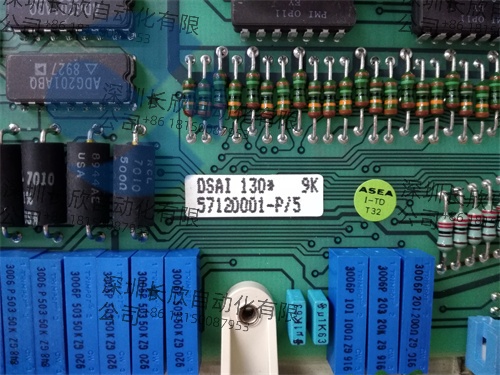

ABB DSMB-01C is widely used in power generation,particularly for controller-I/O network integration.A coal-fired power plant in China deployed 12 of these boards to connect 3 Advant OCS controllers with 96 distributed I/O modules(including ABB DSAO120A AO modules and DSAI130A AI modules);the Profibus DP ports enabled high-speed data exchange,ensuring boiler feedwater control signals were transmitted in<10ms—optimizing water flow and reducing fuel consumption by 6%.The board’s ATEX certification also allowed safe operation in the plant’s hazardous fuel storage area.

In the petrochemical sector,the board synchronizes reactor process data.A refinery in Saudi Arabia used ABB DSMB-01C to connect 4 crude oil distillation columns’control systems to a central Advant OCS;the Modbus RTU port transmitted pressure,temperature,and flow data from 48 sensors,while the AFB port synchronized valve control signals—enabling centralized monitoring and reducing process variation by 8%.The board’s isolation feature prevented voltage surges from one column affecting the entire network,avoiding unplanned shutdowns.

Heavy manufacturing industries rely on the board for production line device interconnection.An automotive assembly plant in Japan used ABB DSMB-01C to connect 32 robotic welding arms,16 conveyor belt drives,and 24 quality inspection sensors to the Advant OCS system;the Profibus DP ports ensured real-time coordination of welding and conveyor speeds,reducing production cycle time by 12%and weld defect rates by 15%.The module’s DIN rail mounting simplified integration into existing control cabinets,saving installation time by 25%.

Oil and gas drilling operations use the board for wellhead data transmission.An offshore drilling platform in the North Sea used ABB DSMB-01C to connect wellhead pressure sensors,flow meters,and chemical injection pumps to the on-board Advant OCS;the board’s corrosion-resistant components and saltwater environment tolerance prevented hardware degradation,while its fast data transmission(≤10ms)allowed remote monitoring of wellhead conditions—enhancing operational safety and reducing on-site personnel requirements by 30%.

Related Products

ABB DSAO120A 3BSE018293R1:Analog output(AO)module compatible with ABB DSMB-01C,featuring 8-channel 4-20mA output for actuator control in Advant OCS systems.

ABB DSAI130A 3BSE018292R1:Analog input(AI)module paired with ABB DSMB-01C,offering 8-channel 4-20mA input for sensor data collection.

ABB CI830 3BSE013252R1:Profibus DP expansion module for ABB DSMB-01C,adding 2 extra Profibus DP ports to support more slave devices in large-scale networks.

ABB CM572 3BSE013261R1:Ethernet communication module for ABB DSMB-01C,enabling Ethernet/IP protocol support for integration with IoT and cloud monitoring systems.

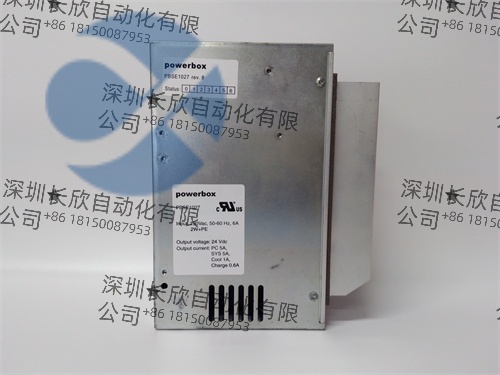

ABB PS860 3BSE004416R1:24V DC power supply unit for ABB DSMB-01C,delivering stable power with overload and short-circuit protection.

ABB TB521 3BSE013211R1:Terminal block for ABB DSMB-01C,simplifying wiring to communication ports and ensuring corrosion-resistant connections.

ABB DSMB-02C:High-temperature variant of ABB DSMB-01C,operating up to+85℃for extreme-heat applications like steel mill furnace control networks.

ABB COM-KIT-DSMB:Calibration and testing kit for ABB DSMB-01C,including a protocol analyzer and software to verify communication accuracy and latency.

ABB RM550 3BSE013220R1:Redundancy management module for ABB DSMB-01C,enabling 1+1 hot standby to ensure uninterrupted communication in mission-critical systems.

Installation and Maintenance

Pre-installation preparation:Before installing ABB DSMB-01C,power off the Advant OCS control cabinet to avoid electrical hazards.Confirm the cabinet’s DIN rail is clean,level,and compliant with EN 60715(35mm width).Check the power supply(18V~30V DC)with a multimeter to ensure voltage stability,and verify compatibility with the Advant OCS controller firmware(version 6.0 or higher)via ABB’s compatibility matrix.For hazardous area installations,confirm the module’s ATEX certification(Ex II 3G Ex nA IIC T4 Ga)aligns with the area classification(e.g.,Zone 2)and use shielded twisted-pair cables for communication ports per IEC 60079-14.

Installation steps:Align ABB DSMB-01C with the DIN rail and push firmly until it clicks into place.Secure the module to adjacent components using the provided mounting clips to prevent vibration-induced movement.Connect the 24V DC power supply to the module’s power terminals,ensuring correct polarity(reverse polarity protection prevents damage,but incorrect wiring may cause temporary shutdown).Wire industrial devices to the communication ports—use shielded Profibus DP cables(for Profibus ports)and twisted-pair cables(for Modbus RTU/AFB ports)to reduce EMI.Connect the module to the Advant OCS backplane via the system bus cable,then power on the cabinet and verify the power LED(green)illuminates;check port status LEDs(yellow)to confirm device connectivity.

Maintenance recommendations:Conduct monthly visual inspections of ABB DSMB-01C—check for loose wiring,dust accumulation on vents(use a soft brush to clean),and ensure LED indicators show normal operation.Every 3 months,test communication latency and data integrity using the ABB COM-KIT-DSMB:send test data packets via each port and verify latency is≤10ms(Profibus DP)and CRC error rates are<0.001%.Every 6 months,tighten terminal screws(torque to 0.5 N·m)and inspect cable shields for damage—loose shields increase EMI susceptibility.If the fault LED(red)illuminates,first check cable connections and power supply—75%of faults are external;for internal issues(e.g.,port failure),contact ABB technical support(do not disassemble the module,as this voids the warranty).

Product Guarantee

ABB provides a 24-month warranty for ABB DSMB-01C from the date of purchase,covering all manufacturing defects—including faulty communication ports,protocol conversion errors,LED indicator malfunctions,or compatibility issues with Advant OCS systems(excluding damage from improper installation,overvoltage,exposure to conditions beyond specifications,or unauthorized modification).All modules are 100%genuine ABB products,verified by serial number through ABB’s global database to guarantee authenticity and compliance with industrial safety standards;non-genuine units are not covered.If the module malfunctions within the warranty period,ABB offers free repair or replacement with expedited shipping to minimize downtime—critical for facilities where communication failure can disrupt system coordination.Additionally,ABB’s technical support team(specialized in Advant OCS communication systems)provides 24/7 remote assistance for installation,protocol configuration,and troubleshooting.For mission-critical applications(e.g.,nuclear power plants),ABB also offers extended warranty options(up to 36 months)and on-site service contracts,ensuring long-term reliability and peace of mind for users.

选择深圳长欣,选择放心,售后无忧大量现货,当天顺丰发货!!!

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!