ALLIED TELESIS AT-2712FXMT-SB-901 990-004100-901

Product Overview

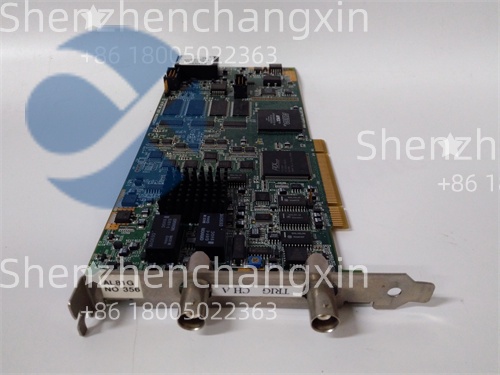

The ALLIED TELESIS AT-2712FXMT-SB-901 990-004100-901 is a high-performance fiber optic network adapter card designed for industrial and enterprise networking applications requiring secure,reliable,and high-speed data transmission.This advanced network interface card from Allied Telesis provides robust connectivity solutions for environments where traditional copper-based networking may be insufficient due to distance limitations,electromagnetic interference concerns,or security requirements.TheALLIED TELESIS AT-2712FXMT-SB-901 990-004100-901represents the company’s commitment to delivering enterprise-grade networking solutions that meet the demanding requirements of modern industrial automation and data center applications.

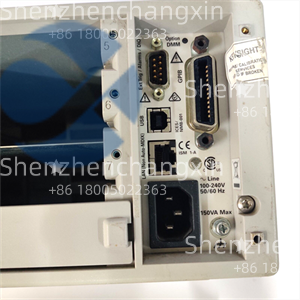

As part of Allied Telesis’comprehensive networking portfolio,theAT-2712FXMT-SB-901 990-004100-901features a PCI Express interface that ensures compatibility with modern server and workstation platforms while providing the bandwidth necessary for high-performance networking.The card supports multi-mode fiber optic connections,enabling data transmission over longer distances than copper cables while maintaining signal integrity and security.TheALLIED TELESIS AT-2712FXMT-SB-901 990-004100-901incorporates advanced networking technologies including VLAN support,QoS management,and broadcast storm suppression,making it suitable for complex network environments where traffic management and security are critical considerations.

TheALLIED TELESIS AT-2712FXMT-SB-901 990-004100-901is engineered to deliver exceptional reliability and performance in demanding operational environments.With support for multiple network standards including IEEE 802.3(Ethernet),IEEE 802.3u(Fast Ethernet),and IEEE 802.3z(Gigabit Ethernet),the adapter ensures seamless integration with existing network infrastructure while providing the flexibility to support future network upgrades.The card’s comprehensive diagnostic capabilities and management software simplify installation,configuration,and ongoing maintenance,reducing total cost of ownership while maximizing network uptime and performance.

Technical Specifications

Parameter Name

Parameter Value

Product Model

ALLIED TELESIS AT-2712FXMT-SB-901 990-004100-901

Manufacturer

Allied Telesis

Product Type

Fiber Optic Network Adapter Card

Interface Type

PCI Express x1

Network Technology

100Base-FX

Fiber Type

Multi-mode

Connector Type

MT-RJ

Maximum Data Rate

100 Mbps

Ports

1 x MT-RJ fiber optic port

Compatibility

Windows,Linux,various server platforms

Standards Compliance

IEEE 802.3,IEEE 802.3u,IEEE 802.3z

Network Features

VLAN support,QoS management,traffic control

Diagnostic Capabilities

Link status monitoring,error detection

Management Software

Included with drivers

Operating Temperature

0°C to 50°C

Storage Temperature

-40°C to 70°C

Relative Humidity

5%to 95%non-condensing

Certifications

CE,FCC,RoHS compliant

Main Features and Advantages

High-performance fiber optic connectivity:TheALLIED TELESIS AT-2712FXMT-SB-901 990-004100-901delivers reliable 100 Mbps data transmission over multi-mode fiber optic cables,providing superior performance compared to traditional copper-based networking solutions.The fiber optic interface enables data transmission over longer distances while maintaining signal integrity and security,making it ideal for applications where electromagnetic interference or security concerns make copper cabling unsuitable.TheALLIED TELESIS AT-2712FXMT-SB-901 990-004100-901’s MT-RJ connector design provides a compact and reliable fiber optic interface that simplifies installation and maintenance while ensuring optimal signal transmission quality.

Advanced networking capabilities:TheALLIED TELESIS AT-2712FXMT-SB-901 990-004100-901incorporates comprehensive networking features including VLAN support,Quality of Service(QoS)management,and broadcast storm suppression.These advanced capabilities enable network administrators to implement sophisticated traffic management policies,prioritize critical network traffic,and maintain network stability even under heavy load conditions.TheALLIED TELESIS AT-2712FXMT-SB-901 990-004100-901’s support for multiple network standards ensures compatibility with existing network infrastructure while providing a migration path to higher-speed networking technologies as requirements evolve.

Robust reliability and management:TheALLIED TELESIS AT-2712FXMT-SB-901 990-004100-901includes comprehensive diagnostic and management capabilities that simplify network administration and troubleshooting.The adapter’s built-in diagnostics monitor link status,detect errors,and provide detailed status information to help network administrators quickly identify and resolve connectivity issues.The included management software provides additional configuration options and monitoring capabilities,enabling administrators to optimize network performance and ensure reliable operation in demanding environments.

Application Field

TheALLIED TELESIS AT-2712FXMT-SB-901 990-004100-901finds extensive application in industrial automation environments where reliable network connectivity is essential for process control and monitoring.In manufacturing facilities,the adapter is used to connect industrial computers,programmable logic controllers(PLCs),and other automation equipment to the plant network,enabling real-time data exchange and remote monitoring capabilities.TheALLIED TELESIS AT-2712FXMT-SB-901 990-004100-901’s fiber optic interface provides immunity to electromagnetic interference,making it particularly suitable for industrial environments where electrical noise can disrupt network communications.

Enterprise data centers and server rooms utilize theALLIED TELESIS AT-2712FXMT-SB-901 990-004100-901for server connectivity applications requiring secure and reliable network connections.The adapter’s PCI Express interface ensures compatibility with modern server platforms while providing the bandwidth necessary for high-performance server networking.TheALLIED TELESIS AT-2712FXMT-SB-901 990-004100-901’s fiber optic connectivity enables longer distance connections between servers and network switches,providing flexibility in data center design and layout while maintaining security through the inherent isolation properties of fiber optic cabling.

Educational institutions and government facilities deploy theALLIED TELESIS AT-2712FXMT-SB-901 990-004100-901for secure network connections in environments where data security and reliability are paramount.The adapter’s fiber optic interface provides enhanced security compared to copper-based networking solutions,as fiber optic cables are more difficult to tap without detection.TheALLIED TELESIS AT-2712FXMT-SB-901 990-004100-901’s support for advanced networking features enables these organizations to implement sophisticated network security policies while maintaining high levels of network performance and reliability.

Related Products

ALLIED TELESIS AT-2712FX/SC-901:Fiber optic network adapter with SC connector for different fiber optic cabling requirements.

ALLIED TELESIS AT-2711FX/SC-901:Similar fiber optic adapter with different connector configuration for specific installation needs.

ALLIED TELESIS AT-2701FX/MT-901:Alternative fiber optic adapter model with similar functionality but different specifications.

ALLIED TELESIS AT-2711FX-MT:Basic fiber optic adapter without the enhanced security features of the SB-901 model.

ALLIED TELESIS AT-2712FX/LC:Fiber optic adapter with LC connector for different fiber optic interface requirements.

Installation and Maintenance

Pre-installation preparation:Before installing theALLIED TELESIS AT-2712FXMT-SB-901 990-004100-901,ensure that the target system meets the minimum hardware requirements and has an available PCI Express x1 slot.Verify that the system’s operating system is supported by the adapter’s drivers and that the latest drivers are available for download from the manufacturer’s website.Prepare the necessary fiber optic cabling and ensure that the connectors are clean and free from damage.Review the installation documentation to understand any specific configuration requirements or considerations for the target network environment.

Maintenance recommendations:Establish a regular maintenance schedule for theALLIED TELESIS AT-2712FXMT-SB-901 990-004100-901that includes periodic inspection of fiber optic connectors for cleanliness and damage,verification of link status and performance metrics,and review of system logs for any error conditions.Keep the adapter’s drivers and management software updated to ensure optimal performance and compatibility with network infrastructure changes.Monitor the adapter’s operating temperature and ensure adequate ventilation around the system to prevent overheating.For critical applications,maintain spare adapters and fiber optic cables to minimize downtime in the event of hardware failure.

Product Guarantee

We guarantee that everyALLIED TELESIS AT-2712FXMT-SB-901 990-004100-901network adapter card meets original manufacturer specifications and undergoes comprehensive testing before shipment.Each unit is backed by our technical support team with extensive experience in networking technologies and industrial automation applications.We provide a standard warranty covering all components and workmanship,with extended support options available for critical applications.Our commitment to quality ensures that you receive a fully functional network adapter capable of meeting the most demanding networking requirements.We maintain complete traceability for all components and provide documentation packages that support regulatory compliance efforts,ensuring that your investment in theALLIED TELESIS AT-2712FXMT-SB-901 990-004100-901delivers reliable performance throughout its operational lifecycle.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!