ABB PSR 3-Phase Soft Starter 07AC91F for Smooth Acceleration

Description:

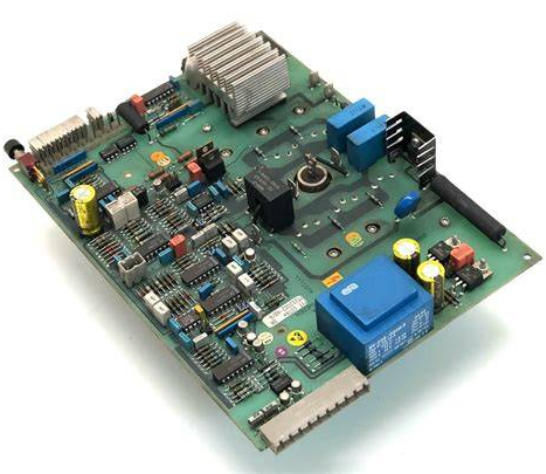

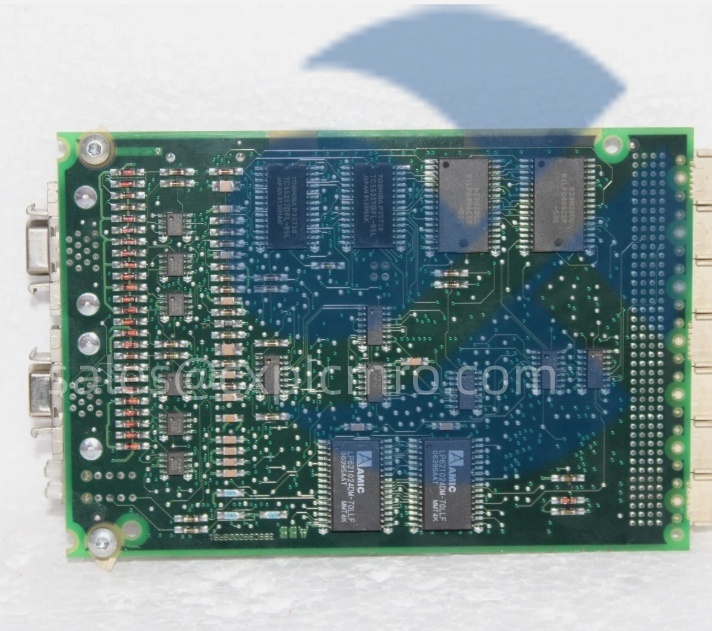

The ABB GJR5252300R3101 07AC91Fis a member of ABB’s versatile PSR series of compact soft starters.It is a 3-phase,solid-state motor controller designed to provide a smooth,controlled start and stop for three-phase asynchronous motors.This model,rated for 75 kW motors,offers a reliable and space-saving alternative to traditional electromechanical starters,reducing mechanical stress on driven equipment and electrical stress on the supply network.

Application Scenarios:

A municipal wastewater treatment plant was experiencing repeated failures of the drive shafts and couplings on its large centrifugal sludge pumps.Each direct-on-line start created a severe mechanical jolt,and the high inrush current caused noticeable voltage sags on the plant’s electrical grid,affecting other sensitive equipment.By retrofitting the pump motors with the ABB GJR5252300R3101 07AC91Fsoft starters,engineers programmed a 15-second linear ramp-up of voltage and torque.This resulted in a smooth,gentle acceleration of the pump impeller,eliminating the damaging torque spikes.The controlled inrush current also kept the plant voltage stable.This single application of the GJR5252300R3101 07AC91Fextended the mean time between failures(MTBF)for the pump mechanical drives by over 300%and eliminated power quality complaints,translating to significant savings in maintenance and downtime costs.

Parameter:

Main Parameters

Value/Description

Product Model/Article Number

GJR5252300R3101(Ordering Code)

Manufacturer Type Designation

PSR…/07AC91F

Manufacturer

ABB

Product Category

3-Phase Electronic Soft Starter

Rated Power

75 kW(at 400V AC)

Rated Current

132 A

Supply Voltage

208-480V AC,50/60 Hz

Control Voltage

24-240V AC/DC(wide range)

Starting Mode

Voltage ramp,current limit,torque control

Protection Features

Overload,phase loss,phase reversal,over temperature,jam,underload

Communication

Optional fieldbus module(e.g.,for Profibus DP)

Enclosure

IP20(open type,for panel mounting)

Control Connections

Screw terminals for control wiring

Technical Principles and Innovative Values:

The ABB GJR5252300R3101 07AC91Futilizes solid-state electronics to manage motor voltage during startup,fundamentally changing how a motor accelerates compared to a brute-force contactor.

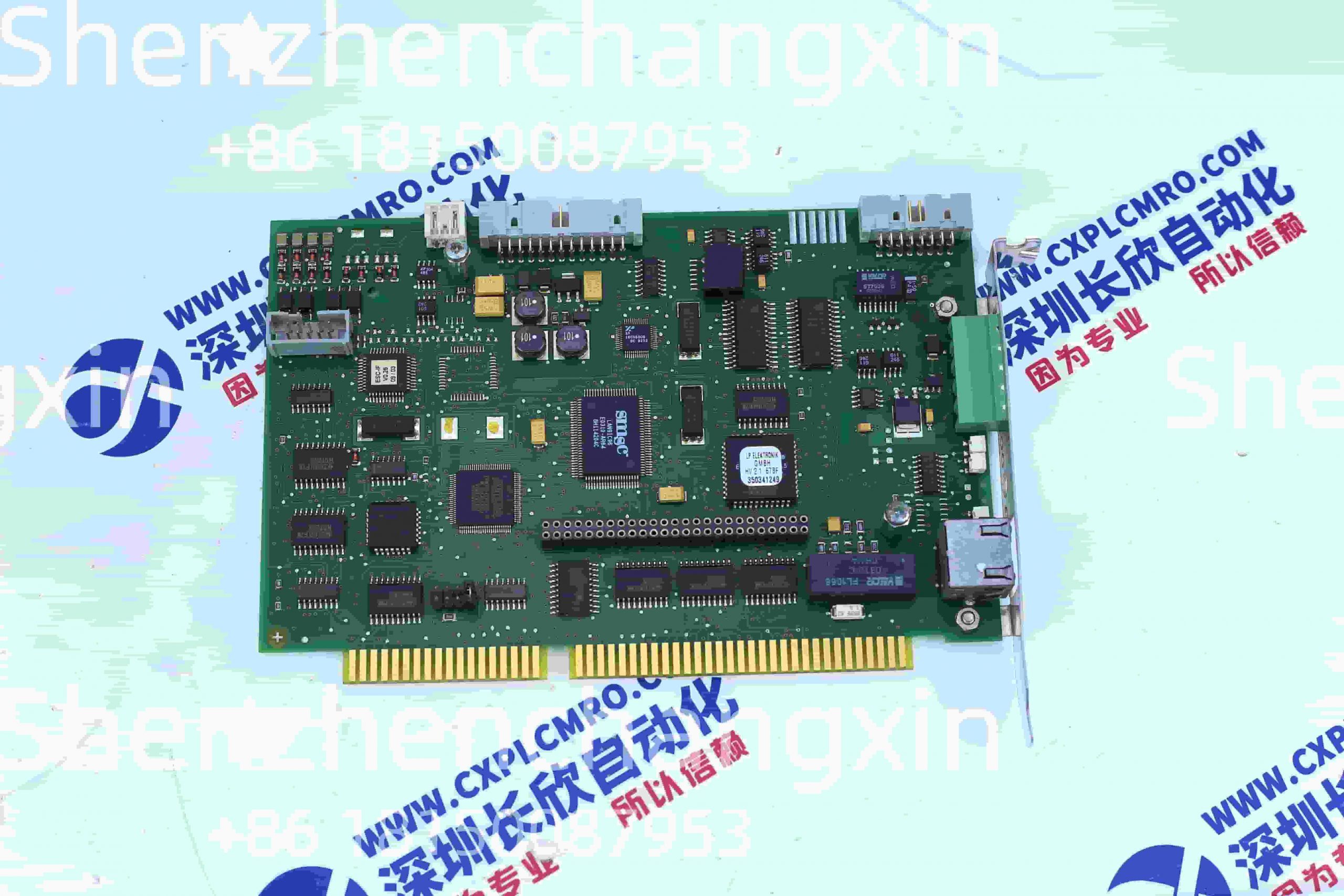

Innovation Point 1:Advanced Thyristor-Based Voltage Ramping.The core of the GJR5252300R3101 07AC91Fis a pair of back-to-back thyristors(SCRs)per phase.During start,a microprocessor-controlled firing circuit gradually increases the conduction angle of these thyristors.This creates a smooth,linear increase in the RMS voltage applied to the motor windings,resulting in a proportional increase in torque.This eliminates the locked-rotor current spike(which can be 6-8x FLC)typical of Direct-On-Line starting,reducing it by up to 70%,thereby protecting the motor and the electrical infrastructure.

Innovation Point 2:Integrated Motor Management&Diagnostics.Beyond simple starting,the unit functions as a smart motor protector.It continuously monitors current in all three phases.Using this data,it provides comprehensive protection against overloads(with Class 10-30 adjustable trip curves),phase imbalance,and phase loss.Its built-in diagnostics can detect abnormal conditions like motor jams or prolonged underload,providing early warnings to prevent equipment damage.This multifunctionality consolidates what would require separate overload relays and protection devices.

Innovation Point 3:Compact Design with Intuitive Programming.Despite its 132A rating,the PSR series,including the GJR5252300R3101 07AC91F,is remarkably compact,saving valuable panel space.Configuration is performed via a simple,menu-driven interface using buttons and a clear digital display on the front,eliminating the need for external programming tools.Key parameters like start time,initial torque,and current limit are easily set,making commissioning fast and user-friendly.

Application Cases and Industry Value:

Case Study:Food Processing Conveyor System Modernization.A bottling plant with a long,heavily loaded conveyor belt system faced chronic issues.Frequent jerky starts caused product topple and spillage,and the high starting current of multiple motors limited the number of conveyors that could be started simultaneously without tripping the main feeder breaker.

The plant standardized on the ABB GJR5252300R3101 07AC91Fsoft starter for all major conveyor drives.Engineers set a”Pump Stop”function along with the soft start,providing a gentle deceleration to prevent liquid sloshing in filled bottles.The reduction in inrush current allowed more conveyors to be sequenced in a shorter time window,increasing line flexibility.The plant manager reported a 40%reduction in product waste from start/stop events and a 15%increase in overall line throughput due to more agile production changeovers.The built-in thermal modeling of the GJR5252300R3101 07AC91Falso prevented two motor burnouts by tripping on early-stage overloads,validating its protective ROI.

Related Product Combination Solutions:

The GJR5252300R3101 07AC91Fis often deployed as part of a coordinated motor control solution.Complementary products include:

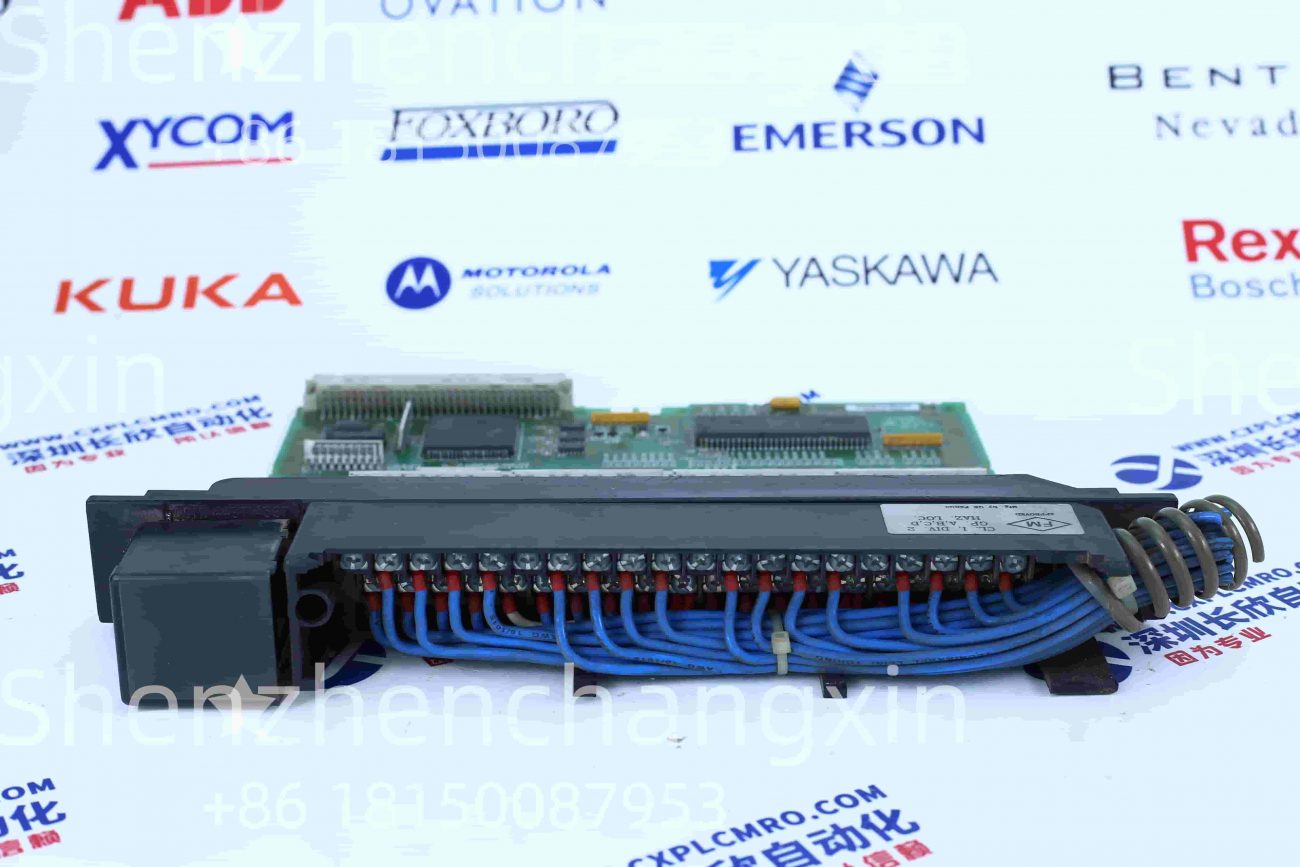

Circuit Breaker or Fuse Disconnect(e.g.,ABB S800 or OS):Provides upstream short-circuit protection and a safe isolation point for the GJR5252300R3101 07AC91Fand the motor.

Bypass Contactor(e.g.,ABB AF contactor):Used in”soft start-run-soft stop”configurations.After the motor reaches full speed,the GJR5252300R3101 07AC91Ftriggers a contactor to bypass the thyristors,improving efficiency and heat dissipation during continuous run.

Fieldbus Adapter(e.g.,ABB FSA-01):Plugs into the soft starter,enabling integration into Profibus DP,DeviceNet,or Modbus RTU networks for remote start/stop commands,parameter adjustment,and diagnostic readouts from a central PLC like an AC 800M.

External Potentiometer or HMI:For applications requiring manual adjustment of start parameters during operation.

Motor Protection Relay(e.g.,ABB CM-MPS):For applications requiring even more advanced protection(e.g.,ground fault,advanced thermistor input),used in conjunction with or instead of the soft starter’s internal protection.

ABB ACS Variable Frequency Drive(VFD):For applications requiring full speed control and high dynamic performance.The GJR5252300R3101 07AC91Fis the cost-optimal choice where only controlled acceleration/deceleration is needed.

Heatsink or Enclosure Fans:For installations in high ambient temperatures or where frequent starts are required,ensuring the GJR5252300R3101 07AC91Foperates within its thermal limits.

Installation,Maintenance,and Full-Cycle Support:

Installation of the ABB GJR5252300R3101 07AC91Ffollows standard industrial practices.The open-type unit is mounted vertically on a panel to ensure natural convection cooling.Power cables from the supply and to the motor are connected to the clearly marked main terminals using appropriate lugs.The versatile control voltage terminals accept a wide range,simplifying integration with existing control circuits(24V DC PLC outputs or 120V AC push buttons).Initial configuration is straightforward using the front-panel keys to set motor FLC,start/stop times,and protection parameters.

Routine maintenance is minimal,primarily involving periodic inspection for dust accumulation on the heatsink and checking terminal tightness.The unit provides comprehensive diagnostic information via its display and fault relay,quickly guiding technicians to the root cause of a trip(e.g.,”Overload,””Phase Loss”).In the rare event of a hardware fault,the modular design allows for relatively straightforward replacement.We provide comprehensive support,from application engineering and selection assistance to on-site commissioning support,spare parts provisioning,and repair services.Our technical team ensures you maximize the performance and longevity of your GJR5252300R3101 07AC91Finvestment.

.jpg)