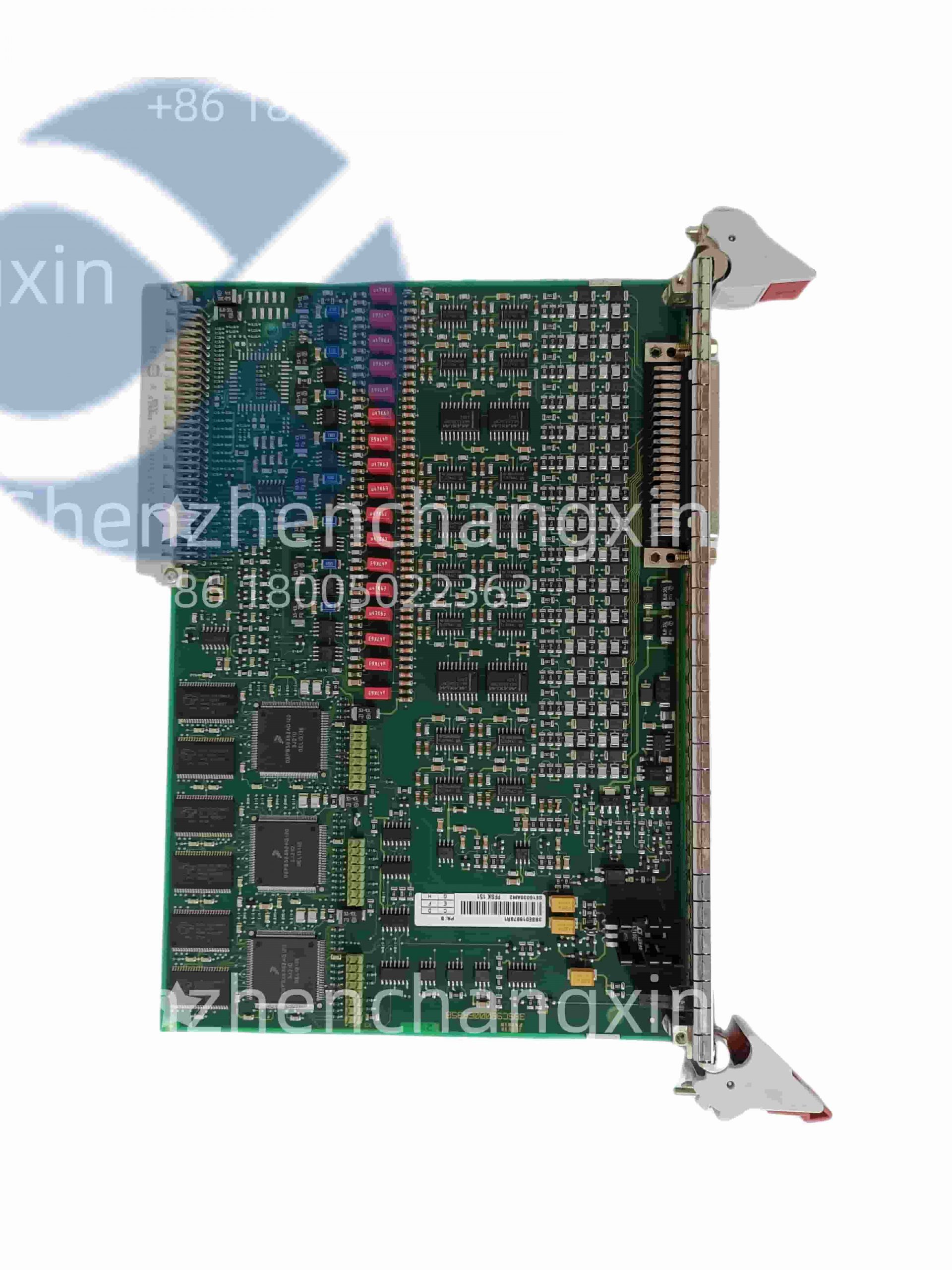

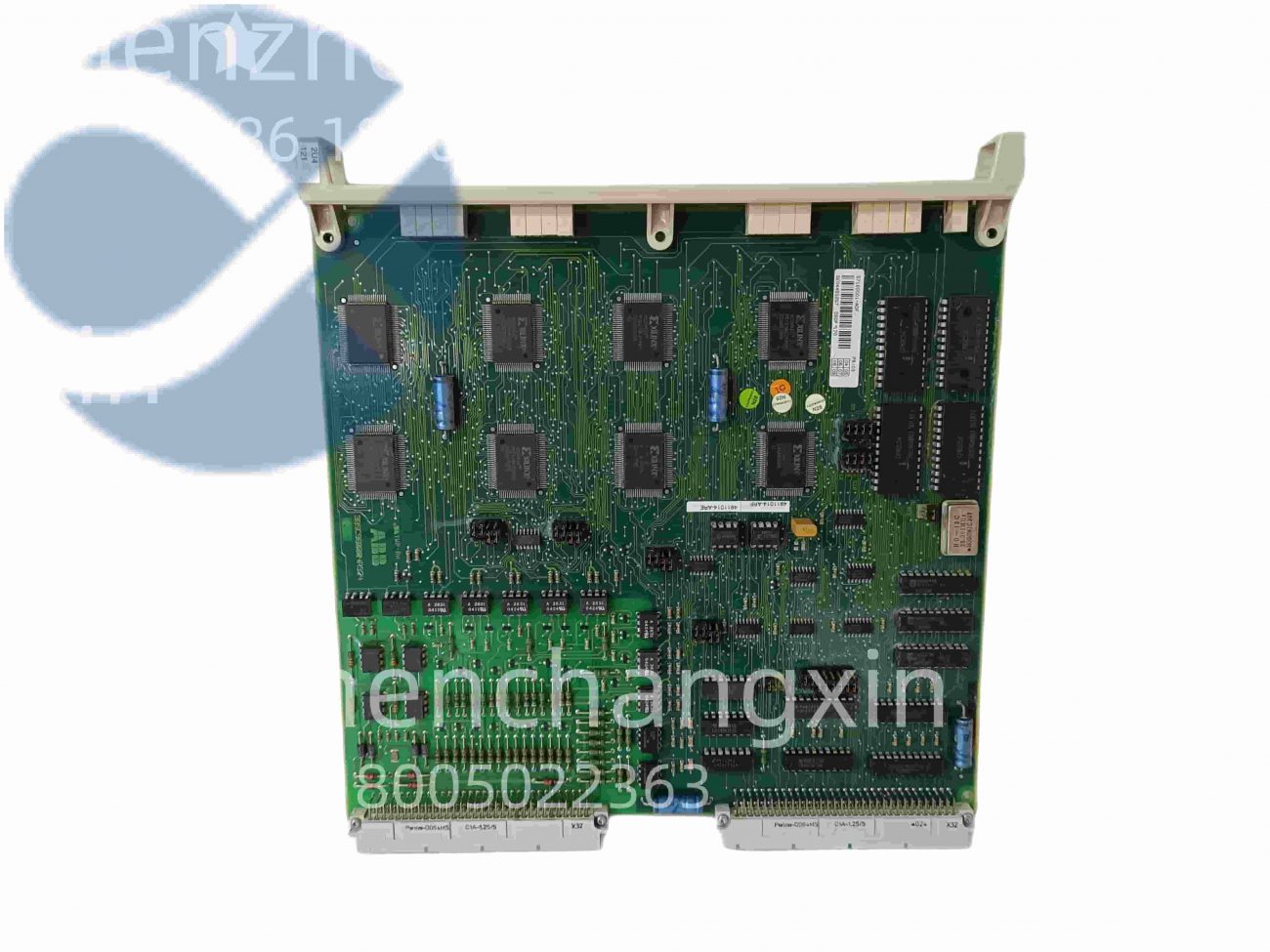

ABB PFSK151 3BSE018876R1 Digital Signal Processing Board

Product Overview

Product Overview

TheABB PFSK151 3BSE018876R1is a high-performance signal processing module designed specifically for industrial automation systems,serving as a critical component in ABB’s Advant OCS(Open Control System)platform.This sophisticated module functions as the”signal processing general”within distributed control systems(DCS),providing exceptional signal acquisition and processing capabilities for complex industrial control tasks.TheABB PFSK151 3BSE018876R1is engineered to handle both analog and digital signals with remarkable precision,making it an indispensable component in demanding industrial environments where accurate signal processing is paramount.

As part of ABB’s comprehensive automation portfolio,thePFSK151 3BSE018876R1offers robust performance across various industrial sectors including power generation,petrochemical processing,and manufacturing applications.The module’s advanced architecture features a 16-bit Motorola 68020 processor and 2MB static RAM,enabling it to process signals with exceptional speed and accuracy.With support for multiple communication protocols including Modbus RTU and IEC 61850,theABB PFSK151 3BSE018876R1ensures seamless integration into existing control systems while maintaining high reliability and operational stability even in the most challenging industrial conditions.

Technical Specifications

Parameter Name

Parameter Value

Product Model

ABB PFSK151 3BSE018876R1

Manufacturer

ABB

Product Type

Signal Processing Module

Processor

16-bit Motorola 68020

Memory

2MB Static RAM

Digital Input Channels

8 channels(24VDC,sink or source)

Digital Output Channels

8 channels(24VDC,0.5A per channel)

Analog Input Channels

4 channels(12-bit resolution,0-20mA or 4-20mA)

Analog Output Channels

2 channels(12-bit resolution,0-20mA or 4-20mA)

Pulse Input Channels

2 channels(24VDC,0.5A maximum)

Communication Protocols

Modbus RTU,IEC 60870-5-101,IEC 60870-5-103,IEC 61850

Supply Voltage

24VDC nominal

Power Consumption

Maximum 12W

Isolation Voltage

≥1000V AC(field side to system side)

Operating Temperature

-25°C to+70°C

Storage Temperature

-40°C to+85°C

Protection Rating

IP20(suitable for cabinet installation)

Physical Dimensions

178 x 51 x 305 mm

Weight

0.5 kg

Installation Method

DIN rail or insertion into Advant OCS rack

Certification Standards

CE,IEC 61131-2

Main Features and Advantages

TheABB PFSK151 3BSE018876R1signal processing module offers several key advantages that make it stand out in industrial automation applications.High precision signal processing capability is one of its most significant features,enabled by the 16-bit Motorola 68020 processor and 2MB static RAM configuration.This combination provides exceptional processing speed and signal acquisition accuracy,ensuring reliable performance in complex control tasks across various industrial sectors.

Multiple signal interface support is another critical feature,with thePFSK151 3BSE018876R1offering comprehensive I/O capabilities including 8 digital inputs/outputs,4 analog inputs,2 analog outputs,and 2 pulse inputs.This versatility allows the module to handle diverse signal types and formats,making it suitable for applications requiring both digital and analog signal processing.The module’s compatibility with 4-20mA and 0-20mA signal standards further enhances its flexibility in industrial environments.

Advanced communication capabilities represent a significant advantage of theABB PFSK151 3BSE018876R1,with support for multiple industrial communication protocols including Modbus RTU,IEC 60870-5-101,IEC 60870-5-103,and IEC 61850.This multi-protocol support ensures seamless integration with various control systems and devices,reducing system integration costs and complexity.The module’s hot-swap functionality enables maintenance without system shutdown,significantly improving operational efficiency and reducing downtime in critical applications.

Application Field

TheABB PFSK151 3BSE018876R1signal processing module finds extensive applications across multiple industrial sectors due to its versatile signal processing capabilities.In the power industry,thePFSK151 3BSE018876R1is widely used in power generation,transmission,and distribution systems for monitoring critical parameters such as voltage,current,frequency,and power quality.Its high precision signal processing ensures accurate measurement and control of electrical parameters,contributing to the stability and reliability of power systems.

In the petrochemical industry,theABB PFSK151 3BSE018876R1serves critical functions in process control systems,where it handles signals from various sensors monitoring temperature,pressure,flow,and level parameters.The module’s robust design and high reliability make it suitable for harsh industrial environments typical in petrochemical plants,ensuring continuous operation and process safety.

Manufacturing applications benefit significantly from thePFSK151 3BSE018876R1’s capabilities in machine control and automation systems.The module processes signals from position sensors,encoders,and other feedback devices,enabling precise control of manufacturing equipment and production processes.Its fast response time and high accuracy contribute to improved product quality and production efficiency in various manufacturing sectors including automotive,electronics,and consumer goods production.

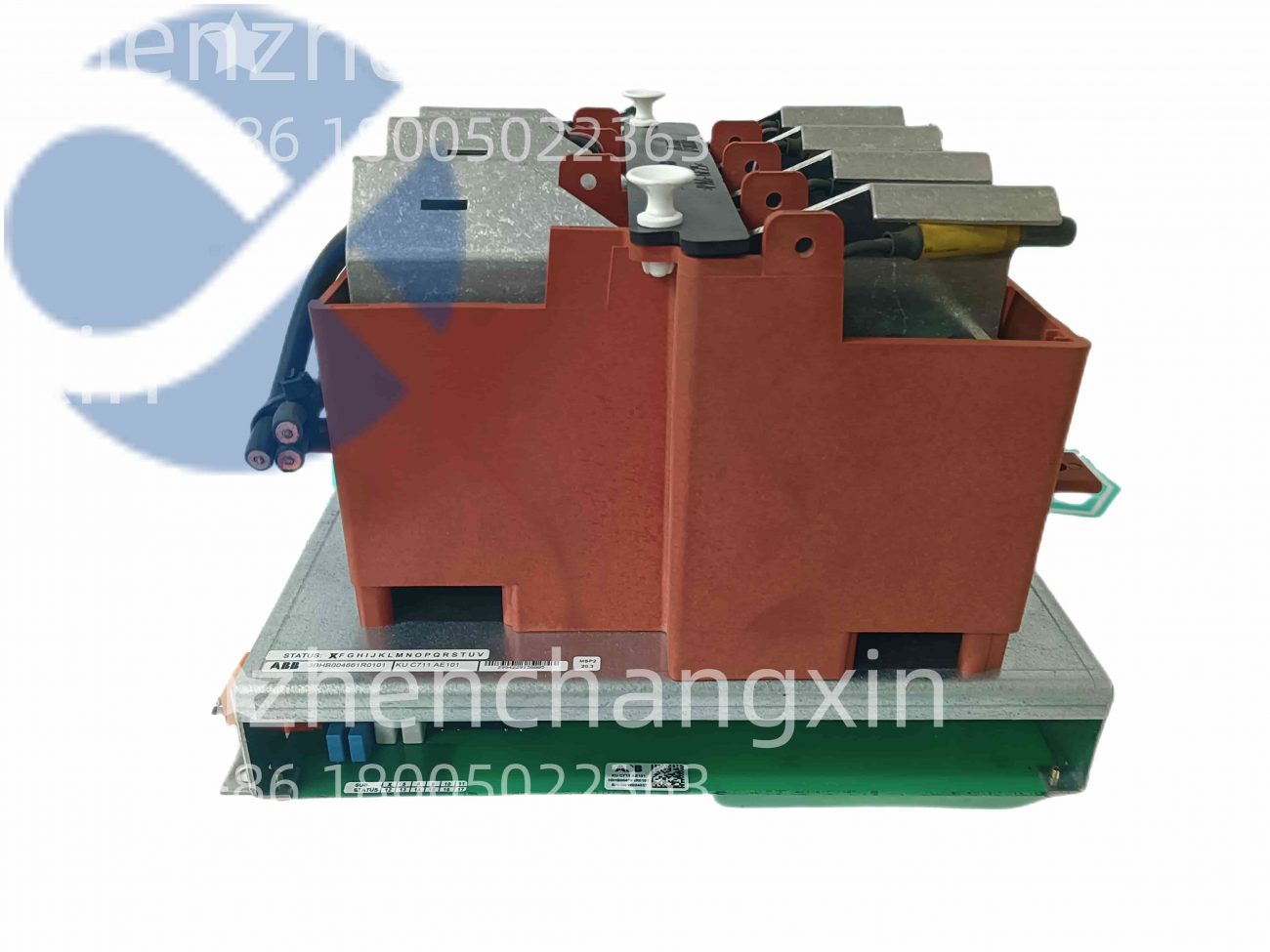

Related Products

ABB PFSK152 3BSE018877R1:Signal concentrator board that complements thePFSK151 3BSE018876R1in signal processing applications

ABB PFSK164 3BSE021180R1:Core component module with enhanced processing capabilities for more demanding applications

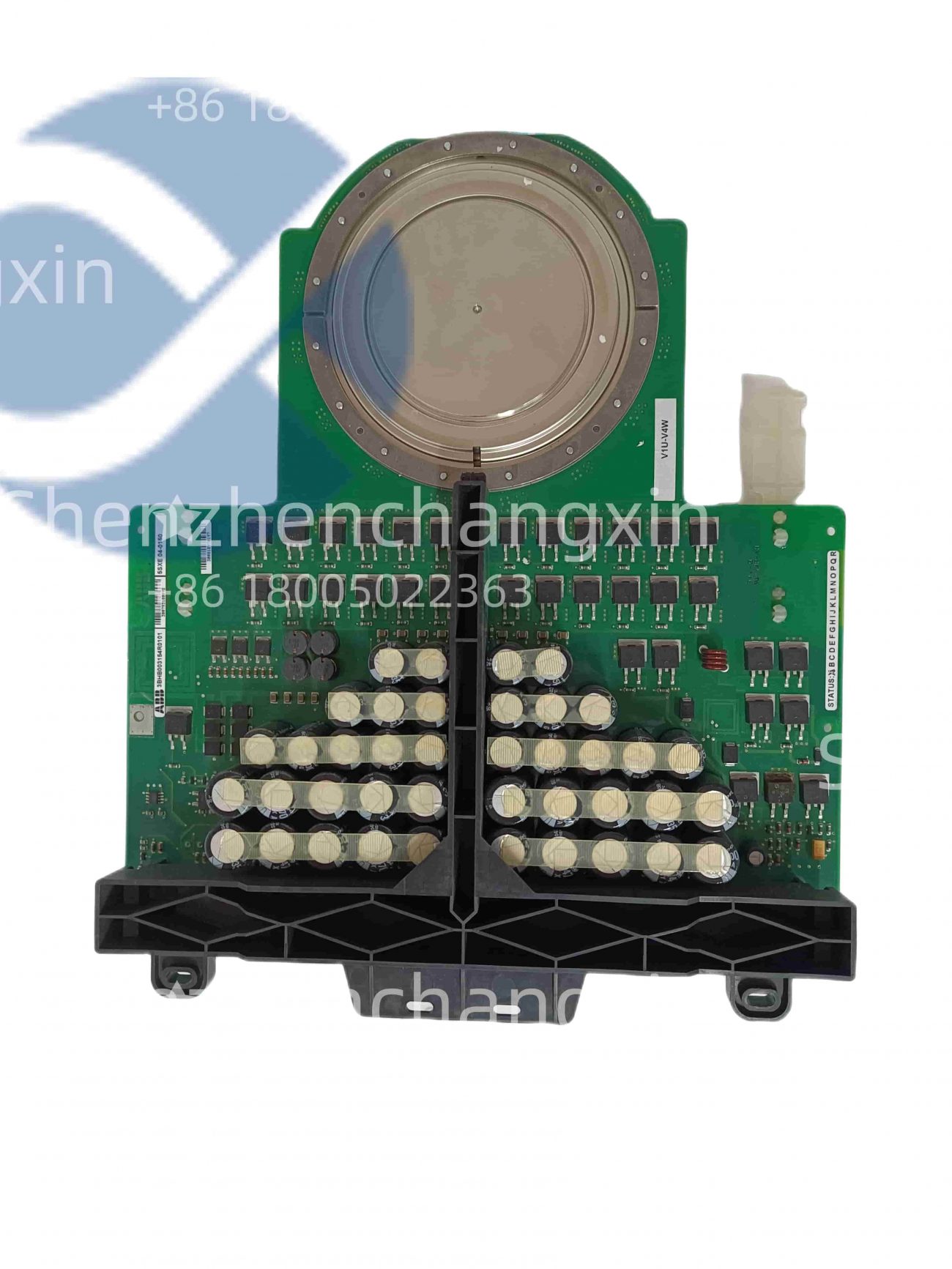

ABB 5SHY4045L0006:Power semiconductor module for high-power applications in industrial automation systems

ABB 3BHB030310R0001:Control and power module for comprehensive automation solutions

ABB DSDP170 57160001-ADF:Pulse counter module for high-speed counting applications in industrial automation

ABB PM866K01 3BSE050198R1:AC800M processor unit providing processing power for systems incorporating thePFSK151 3BSE018876R1

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

Product Overview

Product Overview

Product Overview

Product Overview

Product Overview

Product Overview

Product Overview

Product Overview

Product Overview

Product Overview

Product Description

Product Description