Precision Measurement & Control with NI PXI-6030E DAQ Board

Description

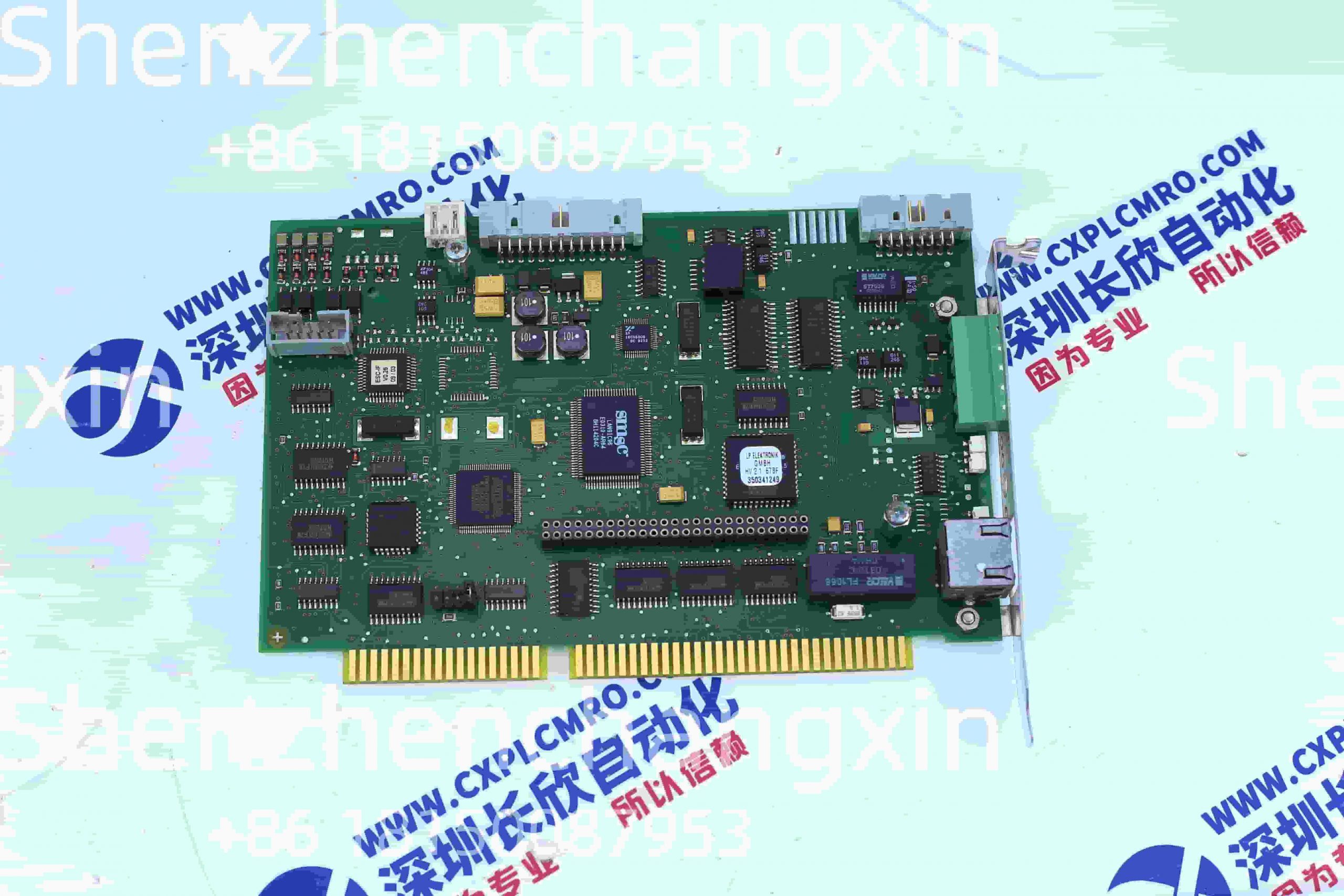

TheNATIONAL INSTRUMENTS PXI-6030Eis a high-performance,multifunction data acquisition(DAQ)board designed for the PXI(PCI eXtensions for Instrumentation)modular instrumentation platform.This 16-bit card delivers a sampling rate of up to 200 kS/s,combining 16 single-ended(8 differential)analog inputs,2 analog outputs,8 digital I/O lines,and two 24-bit counter/timers on a single module.It is engineered for demanding test,measurement,and control applications requiring high accuracy and versatility in an automated,rack-mounted system.

Application Scenarios

In an automotive component validation lab,engineers need to characterize a new electronic control unit(ECU)under various thermal and electrical stress conditions.The test requires simultaneously monitoring multiple analog sensor voltages and temperatures,generating simulated sensor waveforms,and controlling relay banks for load switching—all while maintaining precise synchronization.TheNI PXI-6030E,installed in a PXI chassis alongside other instruments,serves as the central DAQ hub.It acquires all analog signals with high resolution,generates the required analog waveforms,and uses its digital I/O to control the test sequence,all synchronized by its internal timers.This integrated approach,centered on thePXI-6030E,automates a complex test procedure that would otherwise require a rack of individual instruments.

Parameter

Specification

Product Model

PXI-6030E

Manufacturer

National Instruments

Platform

PXI(3U Form Factor)

Product Type

Multifunction Data Acquisition(DAQ)Board

Analog Inputs

16 Single-Ended/8 Differential

AI Resolution

16 Bits

Max Sampling Rate

200 kS/s(aggregate)

Analog Outputs

2 Channels,16-bit,1 kS/s

Digital I/O

8 Lines(5V TTL/CMOS)

Counter/Timers

2 x 24-bit

Input Range

±0.1V to±10V(software selectable)

Connector

68-pin high-density VHDCI connector

Key Features

DMA Support,Analog Triggers,Calibrated Accuracy

Technical Principles and Innovative Values

ThePXI-6030Eembodies the core advantages of the PXI platform:integration,synchronization,and software-defined functionality.

Innovation Point 1:High Integration in a Modular Format.The primary innovation is the consolidation of multiple instrument functions—a precision voltmeter,an arbitrary waveform generator,a digital I/O card,and counter/timers—onto a single 3U PXI module.This integration drastically reduces the size,cost,and complexity of test systems compared to using standalone benchtop instruments.

Innovation Point 2:High-Accuracy,Calibrated Measurements.The board is designed for accuracy,not just speed.With 16-bit resolution and software-selectable input ranges,it can make precise measurements from millivolt-level signals.Its calibration constants are stored on-board,ensuring measurement integrity over time and temperature,which is critical for R&D and quality assurance applications.

Innovation Point 3:Synchronization and Timing via PXI Backplane.A key advantage over equivalent PCI cards is the PXI platform’s built-in timing and triggering.ThePXI-6030Ecan use the PXI backplane’s 10 MHz reference clock and trigger lines to achieve precise synchronization with other PXI modules(e.g.,additional DAQ cards,switches,RF instruments)in the same chassis,enabling complex,multi-channel synchronized systems.

Application Cases and Industry Value

Case Study:Accelerating Aerospace Sensor Calibration.An aerospace company needed to automate the calibration of dozens of pressure transducers.The manual process was slow and prone to human error.They developed an automated calibration station using a PXI chassis with anNI PXI-6030Eas the core.The DAQ card’s analog outputs controlled a precision pressure source,while its analog inputs read the output of the transducer under test and a reference standard.The system,programmed with NI LabVIEW,automatically stepped through pressure setpoints,recorded data,and generated calibration certificates.ThePXI-6030E’s accuracy and reliability were crucial for meeting the stringent calibration standards.This automation reduced calibration time by over 80%and improved data quality.

Related Product Combination Solutions

TheNI PXI-6030Eis the central DAQ component within a larger PXI system.

PXI Chassis(e.g.,NI PXI-1042Q):The mainframe that provides power,cooling,and the high-speed backplane for thePXI-6030Eand other modules.

PXI Controller(e.g.,NI PXI-8106):The embedded computer that runs the test software(e.g.,LabVIEW,LabWindows/CVI)and controls thePXI-6030E.

Screw-Terminal or BNC Breakout Box(e.g.,NI BNC-2090/SCB-68):An interface block that provides easy connection of analog and digital signals to the card’s 68-pin connector.

Other PXI Modules:Additional cards for specific needs,such as high-speed digitizers,RF analyzers,or switch modules,all synchronized within the same chassis.

NI-DAQmx Driver Software:The essential software driver that provides the API for configuring and controlling thePXI-6030Efrom application software.

Installation,Maintenance,and Full-Cycle Support

Installation and Maintenance:Installing thePXI-6030Einvolves powering down the PXI chassis,inserting the card into an available slot,and securing it.The primary”installation”is software-based:installing the NI-DAQmx drivers and the appropriate application development environment(e.g.,LabVIEW).The card requires minimal physical maintenance.The most critical task is periodic calibration(e.g.,annually)using a certified metrology standard to maintain its specified accuracy,a service often provided by National Instruments or accredited third parties.

Our support for theNI PXI-6030Eacknowledges its role in critical test and measurement systems.We provide fully tested and certified legacy modules.Our technical team can assist with compatibility verification for modern operating systems and software.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!