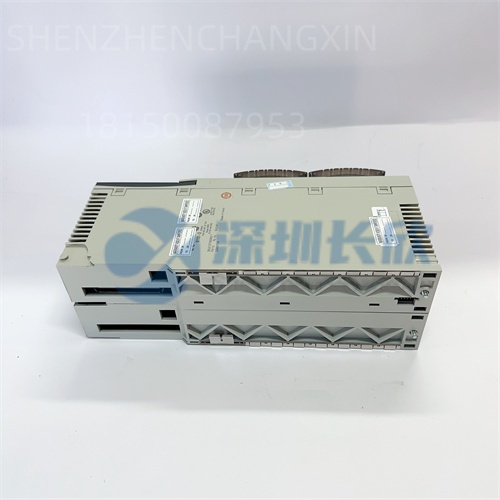

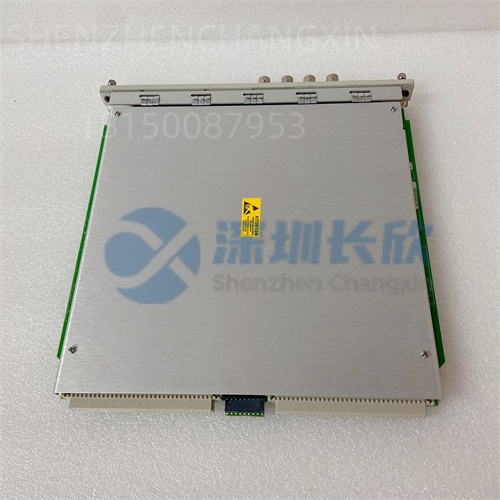

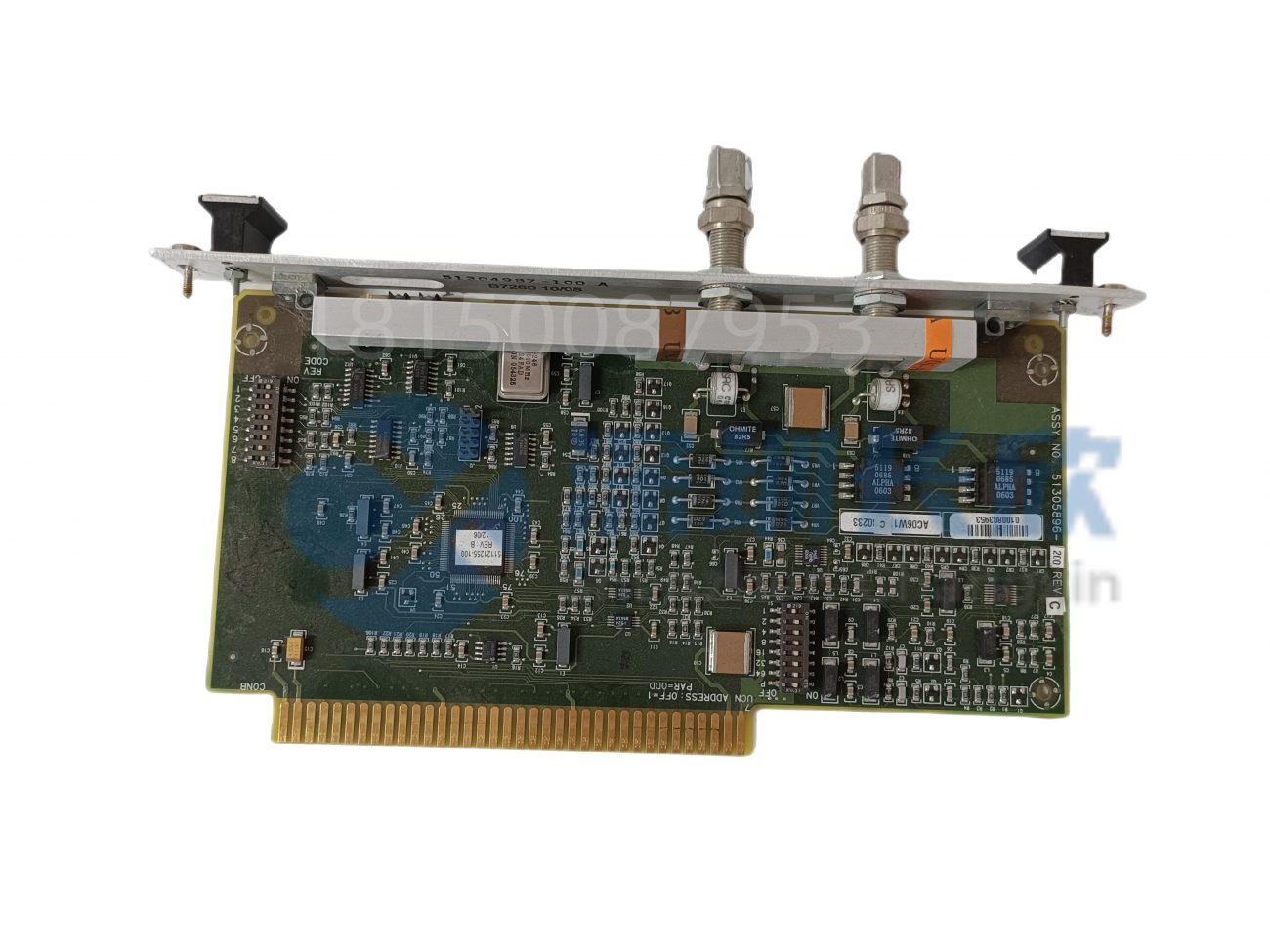

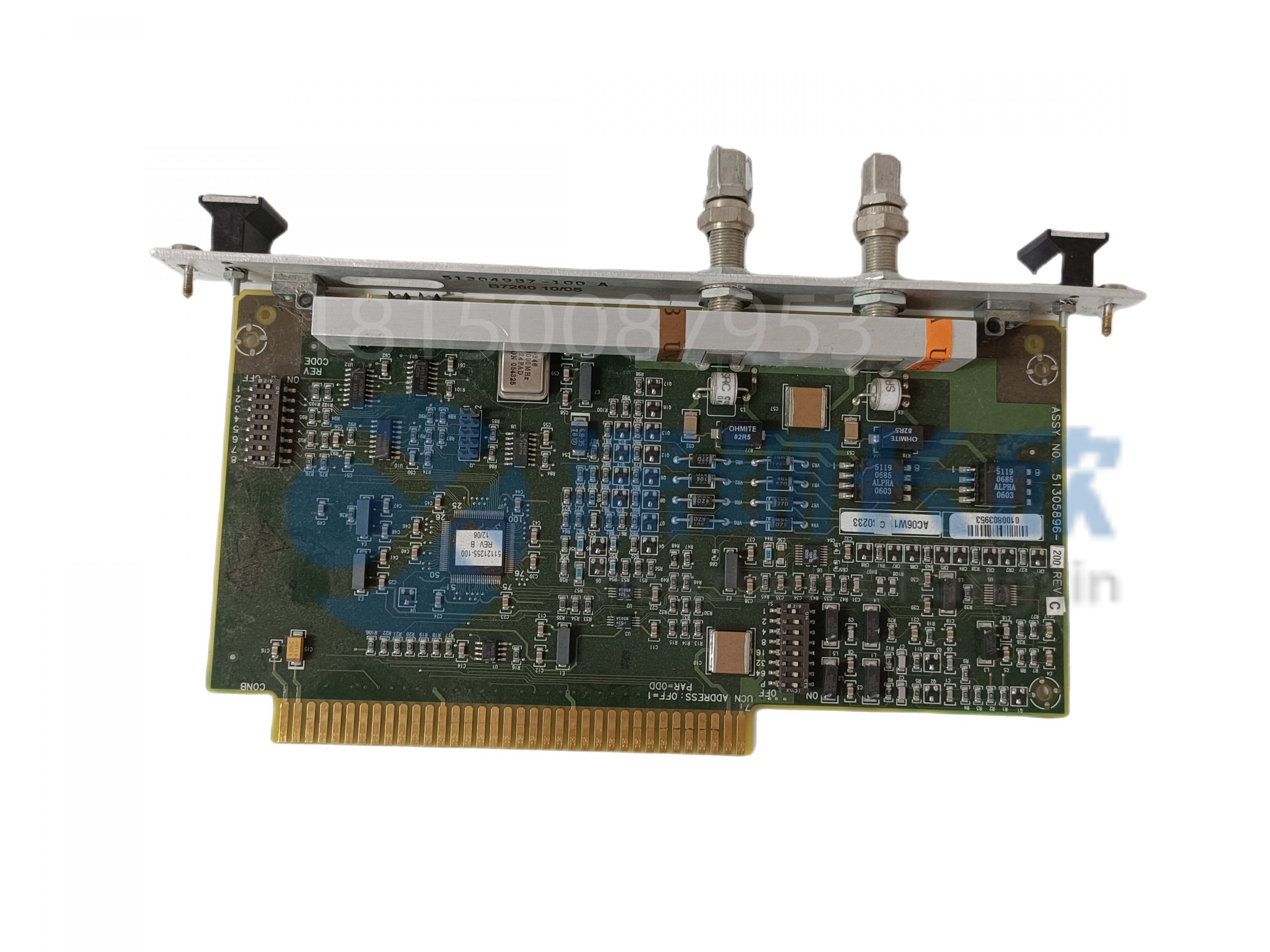

Schneider 140CPU67260 CPU Module | High-Performance Redundant Controller

Description

The Schneider Electric 140CPU67260 is a high-performance, multi-mode Unity hot standby (HSBY) processor within the Modicon Quantum programmable logic controller (PLC) and distributed control system (DCS) platform . Designed as the brain of complex and large-scale industrial automation systems, it features a powerful 266 MHz processor, substantial memory, and built-in support for hardware redundancy . Its “multi-mode” capability allows it to efficiently handle real-time control, data processing, and communication tasks simultaneously, making it suitable for demanding applications in sectors like power generation, oil & gas, and manufacturing where system availability and processing power are paramount .

Application Scenarios

In a sprawling automotive manufacturing plant, a body-in-white welding line involves hundreds of robots, welding controllers, and safety devices that must operate in perfect synchrony. A controller failure could halt the entire production line, costing tens of thousands of dollars per minute in downtime. The Schneider 140CPU67260 is deployed as the central controller in a redundant configuration. The primary CPU executes the complex coordination logic for all stations, while the standby CPU mirrors its state in real-time. If the primary unit fails due to a hardware fault, the system automatically switches to the standby 140CPU67260 within milliseconds, preventing a line stoppage . Furthermore, its multi-mode architecture allows it to not only control the robots (real-time mode) but also collect weld quality data (data processing mode) and communicate production statistics to the plant’s Manufacturing Execution System (MES) via Ethernet (communication mode) concurrently . This addresses the critical pain points of production continuity, data integration, and complex, synchronized control in high-speed manufacturing.

Parameter

Based on technical specifications from product documentation and distributor information .

Technical Principles and Innovative Values

The 140CPU67260 builds upon the robust Quantum platform, emphasizing parallel processing capability and integrated multi-network connectivity.

Innovation Point 1: Multi-Mode Processing Architecture for Concurrent Task Execution. Unlike traditional PLCs that primarily focus on scan-based control, the 140CPU67260 employs a multi-mode processing architecture . It can partition its resources to simultaneously handle real-time deterministic control loops, background data processing and logging, and asynchronous communication protocols without one task significantly impacting the performance of others . This is crucial for modern systems that require not just control but also data analytics and vertical integration with IT systems.

Innovation Point 2: Unified Multi-Protocol Communication Backbone. The processor serves as a native communication hub. Beyond its integrated ports, it supports a wide array of optional communication modules (Ethernet, Modbus Plus, Profibus DP, etc.) . This allows a single 140CPU67260 to directly communicate with devices on different fieldbuses (e.g., Profibus DP drives, Modbus RTU instruments, Ethernet/IP scanners) without requiring external gateways. This simplifies network architecture, reduces latency, and lowers hardware costs and complexity .

Innovation Point 3: Enhanced Memory Management and Application Portability. With support for two PCMCIA memory cards, the 140CPU67260 offers flexible memory expansion . This allows engineers to store large application programs, extensive symbol databases, and even production recipes or historical data directly on the controller. A key feature is the ability to store the complete application with symbols on the PCMCIA card, enabling easy backup, transfer, and restoration of entire projects, which greatly simplifies maintenance and system cloning .

Application Cases and Industry Value

Case Study: Integrated Water & Wastewater Treatment Plant Control System Modernization

A regional water authority operated a treatment plant with separate control systems for raw water intake, chemical treatment, filtration, and sludge processing, leading to operational silos and inefficient coordination. The goal was to integrate these into a unified, highly available control system capable of handling over 20.000 I/O points and multiple communication networks.

Implementation & Outcome: A new control architecture was built around a redundant pair of Schneider 140CPU67260 processors. One CPU pair managed the physical process control, leveraging its high I/O capacity and fast scan time. The multi-mode capability was utilized to run a separate, lower-priority task that performed advanced calculations for chemical dosing optimization and energy consumption analysis. The built-in and optional communication ports allowed direct connection to existing Profibus DP motor control centers, Modbus RTU flow meters, and a new Ethernet/IP network for operator stations. The PCMCIA cards were used to store not only the control program but also the complete HMI faceplates and symbol database, allowing for quick offline troubleshooting. The project resulted in a 15% reduction in chemical usage through optimized control, seamless integration of legacy devices, and a control system with 99.99% availability due to the hot standby configuration. The plant manager highlighted the system’s scalability and reduced engineering effort for future expansions.

Related Product Combination Solutions

The 140CPU67260 is the core of a comprehensive Modicon Quantum system:

Quantum I/O Modules (e.g., 140DDI35300. 140ADO02000): Digital and analog input/output modules for interfacing with field sensors and actuators.

Quantum Communication Modules (e.g., 140NOE77101 – Ethernet, 140CRA31200 – Remote I/O Adapter): Modules to extend network connectivity and manage remote I/O drops.

Quantum Power Supply Modules (e.g., 140CPS11420): Provide reliable 24V DC power to the chassis, available in redundant configurations.

Quantum Baseplates/Racks (e.g., 140XBP00600): The backplanes for mounting CPU and I/O modules.

Redundancy Synchronization Module & Cables: Required to establish the high-speed link between the primary and standby 140CPU67260 CPUs in a hot standby setup.

Schneider Electric Unity Pro/Control Expert Software: The integrated development environment for programming, configuring, and debugging the entire Quantum system, including the 140CPU67260 .

Installation, Maintenance, and Full-Cycle Support

Installation: Install the 140CPU67260 module into a compatible Quantum baseplate (e.g., 140CRA31200 series) with system power OFF. Align the module with the guide rails and firmly press it into the backplane connector until it clicks into place. Connect the necessary communication cables (Ethernet for programming/sync, etc.) to the front ports. For a redundant system, install the second CPU in a separate rack or chassis and connect them using the specified synchronization cables and modules. Configure the redundancy parameters in the Unity Pro software.

Maintenance: Regularly monitor the CPU’s front-panel LCD and status LEDs for any fault indications. The memory backup battery should be checked periodically via software diagnostics and replaced proactively according to the manufacturer’s schedule (typically every 3-5 years) to prevent program loss during power outages. Utilize the hot-swap capability in redundant systems for planned maintenance or replacement without process interruption. Ensure that firmware and Unity Pro software versions are compatible.

Full-Cycle Support: We provide comprehensive support for the Schneider 140CPU67260. from initial system design and compatibility verification to supplying guaranteed genuine or certified refurbished modules. Our technical team can assist with redundancy configuration, complex network integration, troubleshooting, and planning migration paths to newer Schneider platforms like Modicon M580 when the time comes for technological refresh.

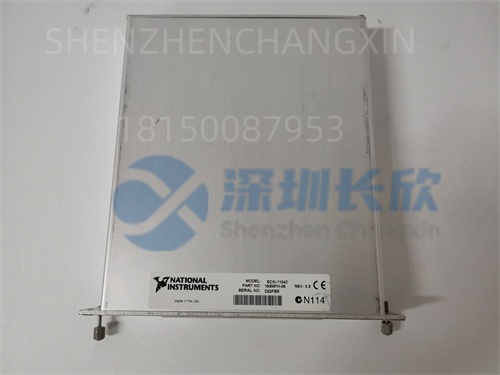

Description

Description

Description

Description