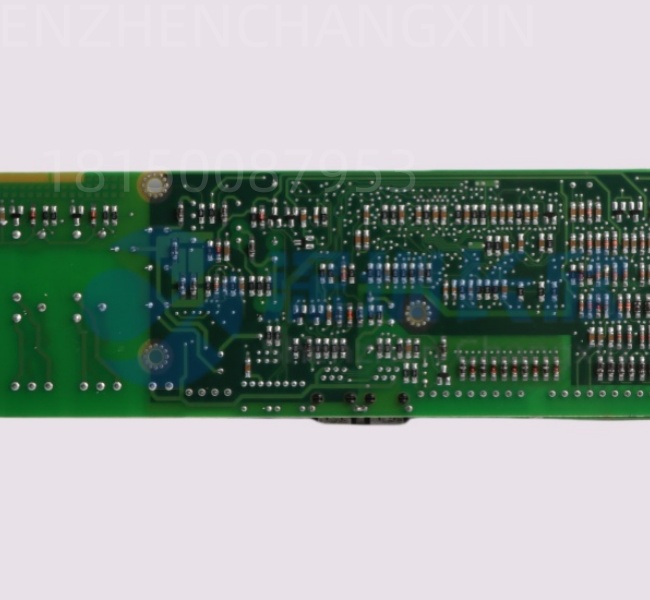

TRICONEX 4352AN: 16-Channel High-Integrity Digital Output Module for TMR Safety Systems

Description

The TRICONEX 4352AN is a 16-channel, high-integrity digital output module from Triconex, a leading brand in safety instrumented systems (SIS) and triple modular redundant (TMR) automation solutions. Designed for use in mission-critical applications, this module provides reliable, fault-tolerant control of final elements such as solenoid valves, motor starters, and circuit breakers. It is engineered to meet the stringent requirements of Safety Integrity Level (SIL) 3 applications, ensuring that safety functions are executed without compromise.

Application Scenarios

In a large offshore oil and gas production platform, the emergency shutdown (ESD) system is the last line of defense against uncontrolled hydrocarbon release. A failure in the digital output module controlling the wellhead shut-off valves could have catastrophic consequences. The platform’s safety system relied on the TRICONEX 4352AN to drive these critical valves.

During a routine test, one channel of the module detected an internal fault and automatically de-energized the corresponding valve actuator, while the other two channels in the TMR configuration maintained control of the remaining valves. The system logged the fault, alerted operators, and initiated a safe shutdown sequence without any spurious trips. The ability of the 4352AN to detect and isolate faults in real time preserved both safety and operational continuity, demonstrating why Triconex modules are the gold standard in high-risk industries.

![]()

![]()

Technical Principles and Innovative Values

Innovation Point 1: Triple Modular Redundancy (TMR) Architecture – The TRICONEX 4352AN is designed to operate in a TMR configuration, where three identical modules process the same output commands in parallel. A hardware voter determines the correct output state by a 2-out-of-3 majority logic, masking any single module failure and ensuring continuous, safe operation.

Innovation Point 2: Advanced Fault Detection & Diagnostics – Each output channel is continuously monitored for faults such as open circuits, short circuits, and contact welding. Diagnostic information is transmitted to the Triconex controller, enabling predictive maintenance and reducing the risk of undetected failures.

Innovation Point 3: Galvanic Isolation – The relay-based output design provides complete electrical isolation between the control logic and field wiring. This prevents high-energy transients or ground loops from propagating back into the safety system, enhancing reliability and protecting sensitive electronics.

Innovation Point 4: High-Integrity Signal Processing – The module uses pulse testing and dynamic self-checking techniques to verify the integrity of its internal circuitry and communication paths. This ensures that the output state is always consistent with the voted command, even in the presence of electromagnetic interference (EMI).

Application Cases and Industry Value

A major refinery in the Middle East upgraded its fire and gas (F&G) system to a Triconex TMR platform to comply with updated safety regulations. The TRICONEX 4352AN modules were deployed to control the actuation of deluge valves, firewater pumps, and emergency isolation dampers.

During a plant-wide F&G test, a spurious signal from a faulty field sensor was detected. The TMR system, including the 4352AN modules, correctly identified the anomaly and prevented an unnecessary activation of the deluge system, avoiding a $500.000 loss in production downtime. Simultaneously, the system’s diagnostics pinpointed the faulty sensor, allowing for its replacement during the next scheduled maintenance window. The refinery’s safety manager stated, “The Triconex system, and specifically the 4352AN modules, gave us the confidence that our safety functions are not only effective but also immune to false trips.”

Related Product Combination Solutions

To implement a complete TMR safety system with the TRICONEX 4352AN, these components are often used together:

TRICONEX 3721 Analog Input Module: For acquiring process variables (e.g., pressure, temperature) to determine trip conditions.

TRICONEX 3008 Main Processor: The TMR controller that executes safety logic and sends commands to the 4352AN modules.

TRICONEX 8312 Power Supply: Provides redundant, regulated 24 VDC power to the I/O modules and mainframe.

TRICONEX 3805E Digital Input Module: For monitoring status of field devices (e.g., limit switches, pushbuttons) in the safety loop.

TRICONEX MP3008 Rack: The chassis that houses the main processor, I/O modules, and power supplies in a TMR configuration.

Triconex TriStation Software: Engineering and configuration tool for programming, testing, and maintaining the TMR system.

Field Wiring Devices (Terminal Blocks, Isolators): Ensure proper signal conditioning and protection for field connections to the 4352AN outputs.

Installation, Maintenance, and Full-Cycle Support

Installation and Commissioning: The TRICONEX 4352AN is installed into a Triconex MP3008 chassis alongside other TMR modules. Proper seating and locking of the module are critical for reliable operation. Field wiring connects to screw terminals for each relay output, with careful attention to load ratings and polarity. Commissioning involves configuring the module’s parameters via TriStation software, performing channel tests, and validating fault detection logic.

Maintenance and Lifecycle Support: Routine maintenance includes inspecting relay contacts for wear (especially in high-cycle applications), verifying terminal tightness, and reviewing diagnostic logs for intermittent faults. Triconex modules support hot-swapping in many configurations, allowing replacement without shutting down the system.

We provide full lifecycle support for the TRICONEX 4352AN, including sourcing genuine modules with traceable certification, technical assistance with system integration, and obsolescence management. Our team ensures your safety-critical systems remain compliant, reliable, and ready to respond when it matters most.

.jpg)

.jpg)