HIMA F2DO160

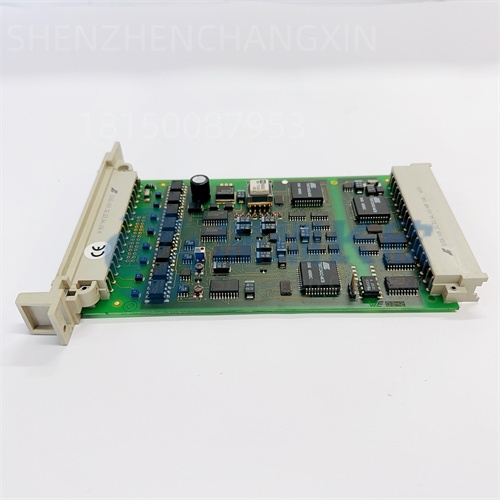

The HIMA F2DO160 is a remote input/output module designed for high-security industrial applications. The following is a detailed description.

The HIMA F2DO160 is a remote input/output module designed for high-security industrial applications. The following is a detailed description.

📊 Core Parameter Overview

Parameter Category

Specifications

Product Model

F2DO160 (also known as F2 DO 16 01 or F2 DO 16 02)

Manufacturer

HIMA Paul Hildebrandt GmbH + Co KG

Product Type

Safety-Related Remote I/O Module

Inputs/Outputs

16 Digital Outputs (Relay Outputs)

Power Supply Voltage

24 V DC

Operating Temperature

-40 °C to +70 °C

Communication Protocols

PROFIBUS DP, Modbus TCP, HART, Secure Ethernet

Safety Rating

SIL 3 (IEC 61508/61511), supports up to SIL 4 (EN 50126/50128/50129)

Protection Rating

IP20

Mounting Method

DIN Rail Mount

Dimensions and Weight

Approx. 255 x 114 x 113 mm, weighing approximately 2-2.5 kg

🔧 Key Features and Design Characteristics

High Safety: The core value of this module lies in its TÜV-certified high Safety Integrity Level (SIL 3), suitable for critical safety applications such as Emergency Stop Systems (ESD) and Safety Instrumented Systems (SIS), ensuring reliable execution of safety functions in hazardous environments.

Powerful Output Capabilities and Diagnostic Functions: The module provides 16 digital outputs. At a maximum ambient temperature of 60°C, the maximum load current of a single channel can reach 2A (simultaneous full load on adjacent channels is not recommended); at 70°C, all channels can be loaded with 0.5A. The module has comprehensive self-diagnostic functions, capable of real-time monitoring of hardware status and line faults, with a diagnostic coverage of up to 99.99%.

Ruggedness and Flexible Integration: Its wide operating temperature range (-40°C to +70°C) and compact metal housing design enable it to withstand harsh industrial environments. The module supports multiple mainstream industrial communication protocols (such as PROFIBUS DP, Modbus TCP, HART, etc.) and can be easily integrated into safety control systems such as HIMatrix or SILworX as a remote I/O station to extend the I/O layer.

🏭 Typical Application Scenarios

This module is primarily used in industrial fields with extremely high safety and reliability requirements:

Oil and Gas: In offshore platforms and refineries, for emergency shutdown (ESD) systems, controlling the closure of safety valves and pumps.

Chemical Industry: In safety instrumented systems (SIS) of chemical plants, controlling safety-related equipment such as pressure relief valves and gas detectors.

Power Energy: In power plants (including new energy fields such as photovoltaic inverter control), ensuring the reliable execution of safety interlocks and shutdown functions.

The HIMA X-DO2401 985210203 is a high-density, safety-rated digital output module engineered for HIMA’s safety instrumented systems (SIS). It is designed to provide reliable, fail-safe control for critical processes in industries like oil and gas, chemical, and power generation, where functional safety is paramount .

The HIMA X-DO2401 985210203 is a high-density, safety-rated digital output module engineered for HIMA’s safety instrumented systems (SIS). It is designed to provide reliable, fail-safe control for critical processes in industries like oil and gas, chemical, and power generation, where functional safety is paramount .