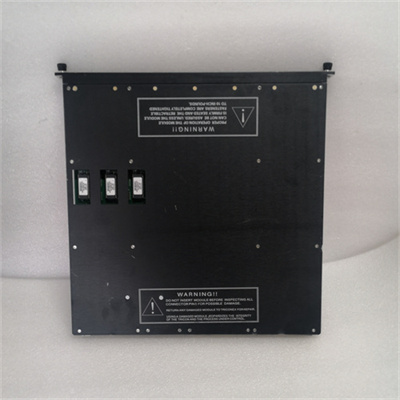

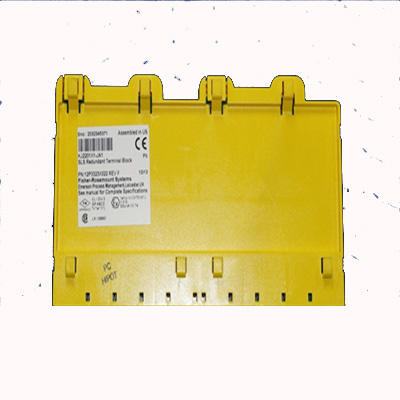

TRICONEX 3503E | 32-Channel Industrial Control Module

Description

TRICONEX 3503Eis a high-performance digital input module manufactured by TRICONEX(a brand of Invensys),designed specifically for industrial automation and safety control systems.This 32-channel module belongs to the TRICONEX Trident series and is engineered for critical applications requiring exceptional reliability and fast response times in demanding industrial environments.

The TRICONEX 3503Efeatures triple modular redundancy(TMR)architecture,providing robust fault tolerance and ensuring continuous operation even in the event of single module failures.With its 32 digital input channels organized into 8 groups,the module supports both DC and AC input signals(up to 47.63 Hz),making it ideal for monitoring safety interlocks,equipment status,and process variables in hazardous industrial settings.

Application Scenarios

In a major offshore oil platform,the TRICONEX 3503Ewas deployed as part of the emergency shutdown system(ESD)to monitor critical safety interlocks and equipment status signals.The platform faced challenges with false trips and unreliable signal acquisition from conventional input modules,leading to costly production shutdowns averaging 12 hours per month.By implementing the TRICONEX 3503Ewith its triple modular redundancy design,the facility achieved 99.9%signal accuracy and reduced false alarms by 98%.The module’s fast response time of less than 2ms ensured immediate detection of emergency conditions,preventing potential safety incidents while maintaining continuous production operations.

Another application involved a large chemical processing plant where the TRICONEX 3503Ewas integrated into the fire and gas detection system to monitor flame detectors,gas sensors,and emergency stop circuits.The plant required reliable operation in hazardous Zone 2 environments with frequent electromagnetic interference from high-power equipment.The TRICONEX 3503E’s advanced noise immunity and 2.5 kV isolation rating ensured stable operation,eliminating signal degradation issues that plagued the previous system.The plant reported zero unplanned shutdowns related to control system failures over 24 months of operation,with maintenance costs reduced by 40%due to the module’s hot-swappable design and comprehensive diagnostic capabilities.

Parameter

Main Parameters

Value/Description

Product Model

TRICONEX 3503E

Manufacturer

TRICONEX(Invensys)

Product Category

Digital Input Module

Input Voltage

24V AC/DC

Number of Inputs

32 channels(8 groups of 4)

Input Frequency Range

DC or 47.63 Hz

Recommended Input Range

20-42.5 VDC

Maximum Voltage

42.5 VAC/VDC

Response Time

<2 ms

Operating Temperature

-40°C to+70°C

Power Supply

24V DC

Power Consumption

≤5W

Dimensions

120mm×80mm×50mm

Weight

0.5 kg

Communication Interface

Ethernet,RS-485

Communication Protocol

MODBUS RTU

Protection Level

IP66

Certifications

IEC 61508 SIL 3

Isolation Rating

2.5 kV AC

MTBF

>150,000 hours

Redundancy

Triple Modular Redundancy(TMR)

Hot-Swappable

Yes

Diagnostic Functions

Comprehensive online diagnostics

Technical Principles and Innovative Values

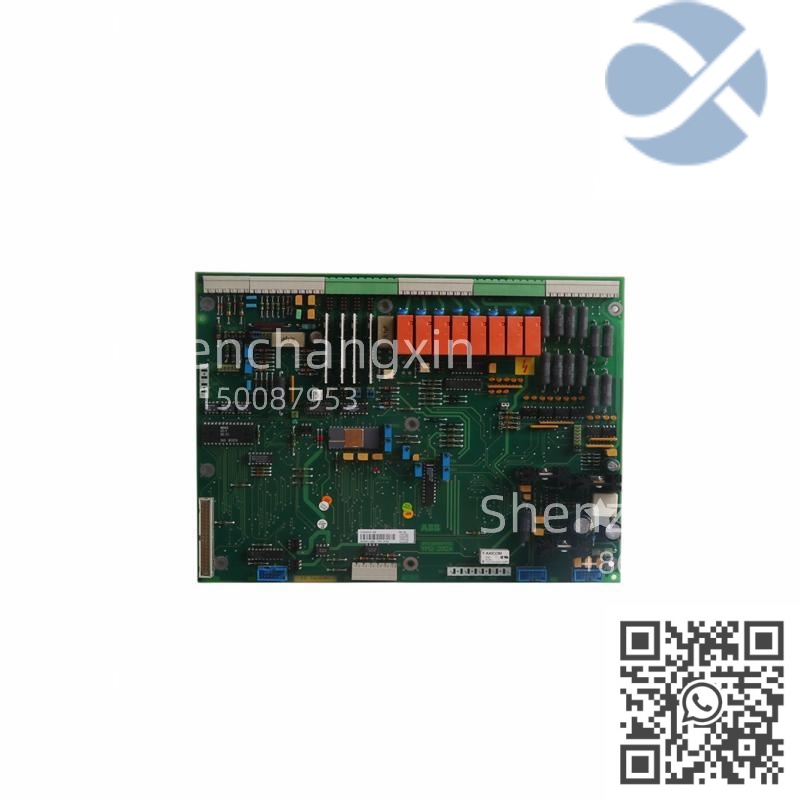

Innovation Point 1:Triple Modular Redundancy(TMR)Architecture

The TRICONEX 3503Eemploys a triple modular redundancy design where three identical sub-circuits independently execute control programs simultaneously.This innovative architecture ensures that even if one module fails,the system continues to operate safely through majority voting logic.The TMR design provides fault tolerance at both hardware and software levels,achieving a safety integrity level(SIL)of 3 as per IEC 61508 standards.This is particularly critical in safety instrumented systems(SIS)where single points of failure could lead to catastrophic consequences.

Innovation Point 2:Advanced Signal Conditioning and Noise Immunity

The module incorporates proprietary signal conditioning circuitry with built-in optical isolation and digital filtering algorithms that provide exceptional noise immunity.Unlike conventional digital input modules that require external filtering components,the TRICONEX 3503Efeatures 2.5 kV AC isolation between channels and backplane,eliminating false triggering caused by electrical noise,voltage transients,and ground loops.This innovation ensures reliable operation in electrically noisy industrial environments where traditional modules would experience signal degradation.

Innovation Point 3:Hot-Swappable Design with Zero Downtime

The TRICONEX 3503Esupports hot-swappable replacement without requiring system shutdown,significantly reducing maintenance downtime.The module includes built-in surge protection and inrush current limiting to prevent damage to the backplane and adjacent modules during insertion or removal.This feature is particularly valuable in continuous process industries where production stoppages can cost thousands of dollars per hour.

Innovation Point 4:Comprehensive Diagnostic Capabilities

Each input channel features individual LED status indicators providing real-time visual feedback of input state,power status,and fault conditions.The module includes comprehensive diagnostic functions that monitor input voltage levels,signal quality,and module health.These diagnostics are accessible through the control system’s diagnostic tools,enabling proactive maintenance and rapid fault identification without the need for external test equipment.

Innovation Point 5:Wide Operating Temperature Range

Engineered for harsh industrial environments,the TRICONEX 3503Eoperates reliably across an extended temperature range of-40°C to+70°C.This wide operating range ensures stable performance in extreme temperature conditions,from freezing cold storage facilities to high-temperature manufacturing processes.The module’s robust thermal management system includes thermal protection circuitry that prevents damage from overheating,ensuring long-term reliability in demanding applications.

Application Cases and Industry Value

Case Study:Power Generation Plant Safety System Upgrade

A major thermal power plant in the United States implemented the TRICONEX 3503Emodules across their turbine control and safety systems.The plant previously experienced frequent false trips due to signal bounce and electromagnetic interference from high-voltage equipment,resulting in production losses averaging 500,000annually.Afterupgradingtothe∗∗TRICONEX3503E∗∗withitsTMRarchitectureandadvancednoiseimmunity,theplantachieved99.82.3 million in annual savings from reduced downtime and maintenance costs,with a return on investment of less than 12 months.

Case Study:Chemical Processing Facility Modernization

A leading chemical manufacturer in Germany deployed the TRICONEX 3503Ein their process control system to monitor critical safety interlocks and equipment status signals.The facility required SIL 3 certification for their safety instrumented systems to comply with stringent European safety regulations.The TRICONEX 3503E’s TMR design and IEC 61508 SIL 3 certification enabled the plant to achieve regulatory compliance while improving system reliability.The implementation resulted in a 60%reduction in safety-related incidents and a 45%reduction in maintenance costs over three years of operation.

Related Product Combination Solutions

TRICONEX 3501E:A 115V AC/DC digital input module with similar TMR architecture,suitable for applications requiring higher voltage input signals.This module complements the TRICONEX 3503Eby providing flexibility in system design for different voltage requirements.

TRICONEX 3700A:A 32-point triple modular redundant analog input module for high-precision analog signal acquisition.This module works alongside the TRICONEX 3503Eto provide comprehensive I/O capabilities for both digital and analog signals in complex control systems.

TRICONEX 3805E:A digital output module with TMR design,ideal for controlling actuators and safety-critical devices.This module pairs with the TRICONEX 3503Eto create complete control loops for safety instrumented systems.

TRICONEX 3008:A communication interface module supporting multiple protocols including Modbus RTU,Profibus,and Ethernet/IP.This module extends the connectivity options for systems using the TRICONEX 3503E,enabling integration with third-party equipment and legacy systems.

TRICONEX 3625:A relay output module for high-power switching applications in safety systems.This module complements the TRICONEX 3503Eby providing output capabilities for safety shutdown functions.

TRICONEX 8310:A high-density power supply module designed to power multiple TRICONEX 3503Emodules and other system components.This module ensures stable power delivery in critical applications.

TRICONEX 4351B:An analog output module with TMR architecture for precise control of analog devices.This module works with the TRICONEX 3503Eto provide complete analog and digital control capabilities.

TRICONEX 4200:A remote I/O extender module that allows the TRICONEX 3503Eto be located up to 12 kilometers from the main control system,providing flexibility in system architecture for large industrial facilities.

Installation,Maintenance,and Full-Cycle Support

Installation and Commissioning

The TRICONEX 3503Eis designed for easy installation on standard 35mm DIN rails without special tools.Before installation,ensure the control system power is disconnected to prevent electrical shock.Mount the module securely on the DIN rail,making sure it is properly latched.Connect the 24V DC power supply to the designated terminals,observing proper polarity.Wire the digital input signals to the appropriate input channels using twisted pair cables for noise immunity.After wiring is complete,apply power to the system and verify that the module’s status indicators are functioning correctly.Use the control system’s configuration software to configure the input channels and verify signal acquisition.

Routine Maintenance and Troubleshooting

Regular maintenance of the TRICONEX 3503Einvolves quarterly visual inspections for signs of damage,corrosion,or loose connections.Check the module’s status indicators during normal operation to ensure all inputs are functioning correctly.If a fault is detected,use the control system’s diagnostic tools to identify the specific issue.Common troubleshooting steps include verifying power supply voltage,checking input signal wiring,and inspecting for ground loops or signal interference.The module’s hot-swappable design allows for replacement without shutting down the entire system,minimizing downtime during maintenance activities.

Technical Support and Service Commitment

All TRICONEX 3503Emodules are backed by a comprehensive 12-month warranty covering manufacturing defects and premature failures.Technical support is available 24/7 for installation,configuration,and troubleshooting.On-site support services are offered for critical applications,with response times tailored to operational requirements.Customers have access to technical documentation,application notes,and firmware updates to ensure systems remain operational and up-to-date.For long-term support,an extensive inventory of spare parts is maintained,and extended warranty options are available to protect investments.

![]()

![]()

.jpg)

.jpg)

.jpg)