ABB UAC389 CPU Module: High-Integration PCB for Advant Series Distributed Control Systems

Description

The ABB UAC389 (identified by part number HIEE410506P104) is a central processing unit (CPU) board designed as a core component for ABB’s legacy Advant Masterpiece and MOD 300 Distributed Control System (DCS) platforms . This printed circuit board (PCB) serves as the system’s brain, executing deterministic control logic, managing system communication via a dedicated backplane bus, and coordinating the operation of field I/O modules. It is engineered for high reliability in continuous, mission-critical industrial processes.

Application Scenarios

In a large pharmaceutical manufacturing facility, a decades-old MOD 300 DCS was responsible for managing a critical fermentation process requiring precise pH and temperature control over extended batch cycles. The system’s heart was an ABB UAC389 HIEE410506P104 CPU board. After over twenty years of uninterrupted service, one of these CPU boards failed, threatening a complete production halt and potential loss of a valuable batch. Because a pre-tested, compatible UAC389 replacement was available in stock, maintenance engineers were able to perform a hot-swap of the board in under an hour. The system restored instantly, running the original, validated control application without any need for re-engineering or recipe recalibration. The plant manager noted, “The UAC389 wasn’t just a component; it was the guardian of our process integrity. Having a reliable spare allowed us to recover in minutes, safeguarding both regulatory compliance and product quality.”

Technical Principles and Innovative Values

Innovation Point 1: Deterministic Control Execution in a Dedicated Environment. The core principle of the UAC389 is its commitment to deterministic real-time control. Unlike general-purpose computing platforms, its dedicated operating environment guarantees that critical control loops, safety interlocks, and batch sequencing logic are executed within a precisely defined and consistent scan time. This predictability is fundamental for process stability, product quality, and operational safety in continuous industries like chemicals and pharmaceuticals .

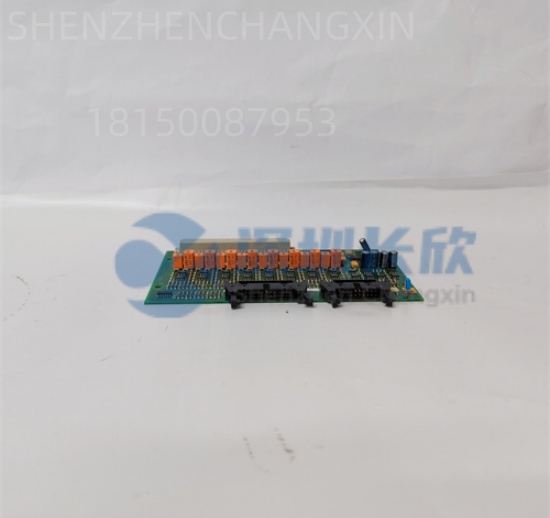

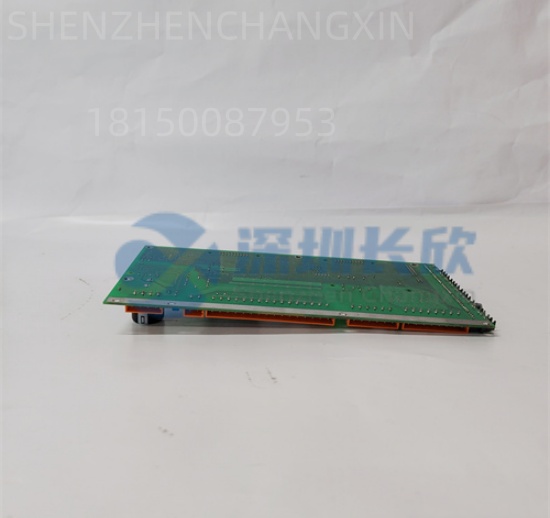

Innovation Point 2: High-Density Component Integration for Enhanced Reliability. The ABB UAC389 HIEE410506P104 integrates the core microprocessor, memory, and bus interface logic onto a single, compact PCB. This high level of integration was a significant design advancement, minimizing internal communication latency between subsystems and, more importantly, enhancing overall reliability by drastically reducing the number of discrete components and interconnects that could potentially fail in the harsh industrial environment .

Innovation Point 3: Strategic Backward Compatibility as a Platform Philosophy. A key innovation embedded in the UAC389’s design was its strict adherence to backward compatibility within the Advant/MOD 300 ecosystem. It ensured electrical and logical compatibility with the existing landscape of I/O modules, communication cards, and field wiring. This philosophy allowed plant operators to upgrade the central processing brain for improved performance or as a spare part replacement without forcing a prohibitively expensive and disruptive complete overhaul of the entire control system infrastructure .

Application Cases and Industry Value

Case Study: Lifecycle Extension in a Pulp & Paper Mill. A pulp and paper mill operating a large Advant Masterpiece system for its digesters and paper machines faced the challenge of maintaining a system beyond its official vendor support lifecycle. The ABB UAC389 CPU boards were identified as critical spares. By sourcing and stocking tested UAC389 HIEE410506P104 units, the mill implemented a robust sparing strategy. When a CPU fault occurred, the quick swap restored control within a single shift, avoiding a multi-day production outage. The mill’s engineering supervisor reported, “The value of the UAC389 goes beyond its technical specs. It represents the ability to sustain our capital-intensive operations for decades, protecting our investment and ensuring operational continuity when modernizing the entire DCS is not immediately feasible.”

Related Product Combination Solutions

ABB UAC380 / UAC381 Modules: Associated communication or application modules that often share the same bus or housing as the UAC389. providing additional network connectivity or specialized computational functions .

ABB UDC Series I/O Modules (e.g., UDC220. UDC300): The various Digital and Analog Input/Output modules which interface directly with the UAC389 CPU via the backplane bus to connect with field sensors and actuators .

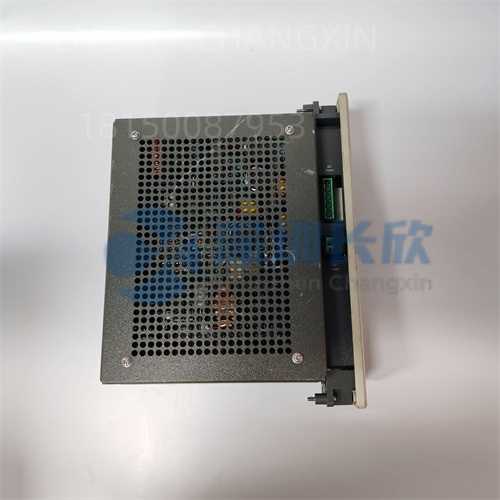

ABB System Racks & Housings: The specific chassis or rack (e.g., Type R modular units) required to house the UAC389 and provide the necessary power distribution and bus infrastructure .

ABB UAC360 / UAC370 Series: Older or alternative CPU/processor units within the Masterpiece or MOD 300 family, which can sometimes serve as functional spares or be used in less complex control applications .

ABB AC 800M Series (e.g., PM865. PM866): The current generation of ABB controllers that represent the modern upgrade and migration path for systems currently relying on the legacy UAC389 .

Installation, Maintenance, and Full-Cycle Support

Installation of the ABB UAC389 HIEE410506P104 is a specialized procedure due to its nature as a bare PCB. It requires careful anti-static handling and typically slides into a designated protective metal housing or a dedicated slot within the control system rack . A critical pre-installation step is verifying that the board has the correct firmware or application software loaded, which is often overlooked in legacy system maintenance .

Routine Maintenance focuses on the health of the host system. This includes regularly checking the stability and quality of the rack’s power supply and ensuring the cooling system is functioning adequately, as the UAC389 is sensitive to overheating . The primary diagnostic tool is the board’s onboard LED status indicators (RUN, FAIL, COMM). A illuminated FAIL LED typically necessitates immediate board replacement .

We provide Full-Cycle Support for these legacy components. Our service begins with expert consultation to confirm the exact compatibility of the UAC389 HIEE410506P104 with your specific Advant or MOD 300 system revision. We supply only genuine, functionally tested modules that have been validated under load to ensure they perform identically to the original. Our technical support can guide you through the replacement process to minimize system downtime. We understand the criticality of these components and maintain strategic inventory to support your long-term operational needs.