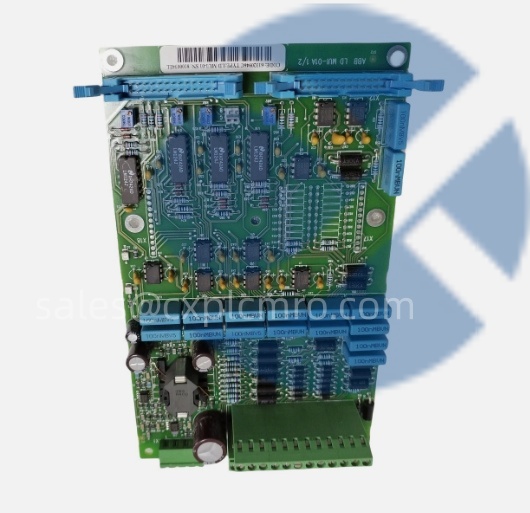

ABB 3AFE61320946P0001 | IGBT Gate Drive Unit

Product Description

Brand:ABB

Model:3AFE61320946P0001

Designation:POS.A6091

Series:ACS800/Medium Voltage Drive Components

Function:IGBT Gate Driver Board

Core Role:Provides isolated,amplified switching signals to control IGBT modules in a power inverter.

ABB 3AFE61320946P0001(POS.A6091)is a high-precision IGBT Gate Driver Boardused within ABB ACS800series variable frequency drives(VFDs)and other power conversion platforms.It acts as the critical interface between the drive’s low-voltage control logic and the high-power Insulated Gate Bipolar Transistor(IGBT)modules.Its primary function is to receive low-power PWM signals,amplify them,and deliver the precise voltage and current required to reliably switch the IGBTs on and off,forming the output waveform to the motor.Genuine ABB component,essential for drive reliability and performance.

Application Scenarios

In a critical mine hoist application,a 2.5MW ACS800 variable frequency drive controls a massive motor that lifts ore from deep underground.The drive must generate near-perfect sinusoidal currents to ensure smooth,controlled acceleration and deceleration of the multi-ton cage,with zero tolerance for unexpected torque pulses.The heart of this power conversion is the inverter section,where high-voltage DC is switched into three-phase AC.Each of the six IGBT modules in this bridge requires a perfect gate signal:fast enough to minimize switching losses,strong enough to overcome internal capacitance,and perfectly isolated to protect the sensitive control electronics from thousands of volts.The ABB 3AFE61320946P0001gate driver board is the component that delivers this perfection.Mounted directly onto or adjacent to an IGBT module,it receives a fiber-optic signal from the main control board.It then generates a robust,+15V/-8V gate drive signal.Its advanced monitoring circuits continuously check for”short circuit”conditions across the IGBT.If a catastrophic fault like a motor phase-to-ground short occurs,the driver detects the resultant excessive collector-emitter voltage(DESAT protection)and can shut down the IGBT within microseconds—a speed far surpassing the main processor’s reaction time—potentially saving the entire IGBT stack from a destructive failure costing tens of thousands of dollars.For the maintenance team,a failing 3AFE61320946P0001might manifest as unbalanced motor currents,overheating,or a cryptic”SHORT CIRCUIT”alarm.Its reliability is non-negotiable;it is the guardian of the drive’s most expensive and mission-critical components.

Key Parameters

Parameter

Value/Description

Product Model

3AFE61320946P0001(Designation:POS.A6091)

Manufacturer

ABB

Product Category

IGBT Gate Driver/Interface Board

Target Device

IGBT Modules in ABB Drives(e.g.,within ACS800 inverter units)

Input Signal

Typically a fiber-optic or electrical PWM signal from the drive’s control board.

Output Signal

Isolated,amplified gate drive voltage(e.g.,+15V to turn ON,-8V to turn OFF).

Isolation Voltage

High(several kV),providing galvanic isolation between low-voltage control and high-voltage power stage.

Protection Features

DESAT(Desaturation)Protectionfor short-circuit detection,Undervoltage Lockout(UVLO)for gate supply monitoring.

Switching Speed

Designed for fast,efficient IGBT switching to minimize losses.

Power Supply

Requires isolated auxiliary DC supplies(e.g.,+15V,-8V,+5V)often generated by an associated DC/DC converter board.

Interface

Connects via pins/connectors to the IGBT module’s gate/emitter terminals and includes feedback signals.

Status Indicators

May include LEDs for power and fault indication.

Mounting

Typically PCB mounted near or directly on the IGBT module’s heatsink assembly.

Primary Function

Reliable switching,protection,and status feedback for a single IGBT or an IGBT half-bridge.

Technical Principles and Innovative Values

The ABB 3AFE61320946P0001is not a simple amplifier;it is a sophisticated,real-time protection and control system for a multi-thousand-dollar power semiconductor.Its design embodies the precision required for modern high-power,high-availability drives.

Innovation Point 1:Intelligent,Ultrafast Short-Circuit Protection(DESAT)

The most critical innovation is its integrated Desaturation(DESAT)protection.During normal operation,a saturated IGBT has a low collector-emitter voltage(Vce).In a short-circuit event(motor fault,arc flash),Vce skyrockets.The 3AFE61320946P0001continuously monitors this Vce via a high-voltage diode.If Vce exceeds a safe threshold for more than a few microseconds—indicating the IGBT is leaving saturation and entering a destructive high-power state—the driver acts independently.It immediately clamps the gate voltage and forces the IGBT into a controlled,soft shutdown mode to minimize voltage spikes,then signals a fault to the main controller.This hardware-based protection operates in<10 microseconds,far faster than any software routine,and is the primary defense against IGBT destruction during faults.

Innovation Point 2:High-Performance,Isolated Gate Driving

The board provides optimal gate driving.The positive turn-on voltage(+15V)is tightly regulated to ensure the IGBT turns on fully with minimal conduction loss.The negative turn-off voltage(-8 to-15V)is crucial for providing noise immunity and preventing false triggering from Miller capacitance effects,especially during high dv/dt switching events.This dual-rail supply ensures clean,crisp switching transitions,which directly reduces switching losses and electromagnetic interference(EMI).The galvanic isolationbetween the input(control side)and output(power side)is achieved with high-quality pulse transformers or optocouplers,rated for the full DC-bus voltage of the drive.This prevents any high-voltage transients on the power stage from propagating back and destroying the drive’s brain.

Innovation Point 3:Comprehensive Diagnostics and Feedback Integration

Beyond just driving,the module acts as a sensor.It monitors its own health and the status of the IGBT.Undervoltage Lockout(UVLO)circuits disable the output if the gate power supplies dip,preventing the IGBT from operating in a linear region where it would overheat and fail.The board typically provides a”Ready”or”Fault”feedback signal to the main control board.This allows the drive’s software to identify which specific IGBT leg has a problem,drastically reducing Mean Time To Repair(MTTR)by pinpointing the faulty sub-assembly instead of forcing a check of all six legs.

Innovation Point 4:Optimized for System Integration and Thermal Management

The board is designed as a mezzanine or plug-in module,forming a complete”driver+IGBT”power cell.This modularity allows for easy replacement and standardizes testing.Its layout is optimized for low stray inductance to prevent parasitic oscillations that can stress the IGBT.It is also engineered to withstand the high temperatures and vibration found in a drive cabinet mounted next to motors and transformers,ensuring long-term reliability.

Application Cases and Industry Value

Case Study:Steel Mill Hot Strip Finishing Mill Drive Retrofit

A major steel producer was experiencing chronic downtime on the finishing stands of its hot strip mill.The existing DC drives were unreliable,causing strip thickness variations and production breaks.They retrofitted the line with modern ABB ACS800AC drives.A year after commissioning,one drive began tripping intermittently with a”SHORT CIRCUIT”alarm on the inverter,halting the line and causing a cobble—a tangled mess of red-hot steel that takes hours to clear.

The maintenance team used the drive’s detailed fault log,which indicated the fault originated from the DESAT protection circuit on Phase U,lower IGBT.This pointed directly to the 3AFE61320946P0001gate driver board or the IGBT itself.Using a thermal camera,they identified the suspect IGBT/driver assembly running hotter than its peers.During a scheduled 4-hour maintenance window,they replaced the entire power cell(IGBT module with its attached 3AFE61320946P0001driver).The drive was back online in 90 minutes.Post-analysis of the old driver revealed a degraded component in its DESAT monitoring circuit,causing it to become overly sensitive and trip on normal current spikes during heavy rolling loads.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!