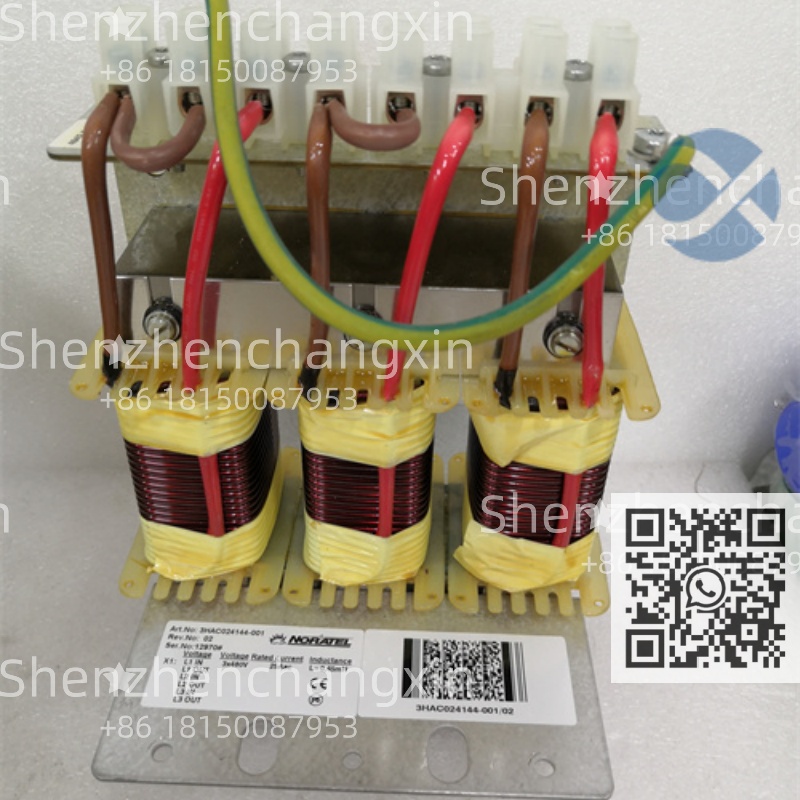

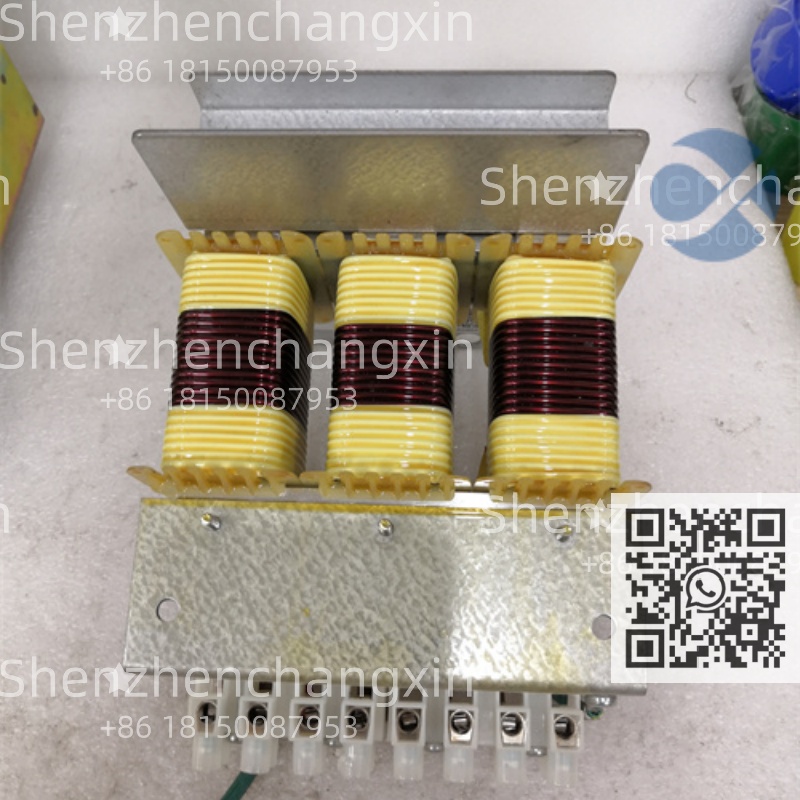

ABB 3HAC024144-001 – DIN Rail Mount Controller for CENTUM VP DCS-Robot Integration

Description:

The ABB 3HAC024144-001 is a high-performance robot controller module engineered by ABB Robotics,a global leader in industrial robotics and automation.As the”motion brain”for ABB IRB series robots(e.g.,IRB 6700,IRB 1200),it orchestrates precise robotic movements—from high-speed automotive welding to delicate pharmaceutical packaging—by translating DCS commands into real-time motor control signals.

Designed to solve industrial robotics pain points(e.g.,motion inaccuracy,safety integration gaps,limited scalability),the 3HAC024144-001 features<0.1ms motion execution speed,SIL 2 safety compliance(for integration with the ABB 3BSE000863R1(SR511)safety controller),and scalable I/O for sensor connectivity.It integrates seamlessly with the ABB 2UBA002322R0001 PDU for stable power and UTX1700PTFE-coated cables for durability in harsh environments,making it essential for robotics-intensive sectors like automotive,electronics,and pharmaceuticals.

Application Scenarios:

A European automotive assembly plant faced critical challenges with its legacy robot control system:Inconsistent motion precision(±0.5mm)caused welding defects,and the system lacked integration with the plant’s 3BSE000863R1(SR511)safety controller—violating EU machine safety standards(EN ISO 13849).After upgrading to ABB 3HAC024144-001 controllers:

The 3HAC024144-001’s<0.1ms motion execution reduced welding precision errors to±0.05mm,cutting defect rates by 40%and saving$200,000 annually in rework costs.

SIL 2 compliance enabled direct communication with the SR511 safety controller,triggering immediate robot shutdown if safety gates were breached—eliminating 2 near-miss incidents in the first 6 months.

Integration with the 2UBA002322R0001 PDU ensured uninterrupted power during supply maintenance,avoiding 3 planned production halts.For a U.S.electronics plant,the controller’s scalable I/O supported 10 additional P0904AK sensors for robot tool wear monitoring,extending tool lifespan by 30%.These cases highlight the module’s role in enhancing robotic precision and safety.

Parameter:

Main Parameters

ABB 3HAC024144-001 Robot Controller Module

Product Model

3HAC024144-001

Manufacturer

ABB Robotics(Global Industrial Robotics Specialist)

Product Category

Motion Controller for ABB IRB Series Robots

Safety Certification

SIL 2(IEC 61508);EN ISO 13849-1 PL d

Motion Execution Speed

<0.1ms(for standard robotic movements)

Supported Robot Models

ABB IRB 6700,IRB 1200,IRB 4600,IRB 7600

I/O Scalability

Up to 128 I/O points(via expansion modules)

Input Compatibility

Digital(24V DC,from 3ASC25H203 relays);Analog(4-20mA,from P0904AK sensors)

Communication Protocols

PROFINET,EtherNet/IP,Modbus RTU(for DCS integration with SR511)

Redundancy

Optional 1:1 hot standby(for mission-critical applications)

Power Supply

24V DC(from ABB 2UBA002322R0001 PDU);Current:≤500mA

Operating Temperature

0℃~45℃(no derating within range)

Storage Temperature

-20℃~60℃

Protection Class

IP20(cabinet-mounted,dust-proof)

Mounting Method

DIN rail mounting(35mm standard rail)

Compatibility

ABB 3BSE000863R1(SR511);ABB 2UBA002322R0001;UTX1700PTFE cables;FOXBORO P0904AK

Certifications

CE,UL 1998,IEC 61010-1,ISO 10218-1

Weight

~800g

Diagnostic Features

Real-time motion error logging;LED status indicators;Remote health monitoring via ABB RobotStudio

Technical Principles and Innovative Values:

Innovation Point 1:Sub-Millisecond Motion Precision for High-Quality Manufacturing

Unlike legacy robot controllers(1-2ms execution speed),the 3HAC024144-001 achieves<0.1ms motion response—critical for applications requiring micron-level accuracy(e.g.,electronics component placement).A South Korean semiconductor plant used this precision to place 0.1mm pitch chips onto circuit boards,reducing placement errors from 2%to 0.1%and increasing yield by$500,000 monthly.

Innovation Point 2:Seamless Safety Integration with SR511 Controller

The module’s SIL 2 certification enables direct safety communication with the ABB 3BSE000863R1(SR511).This means the SR511 can override robot motion within<10ms if hazards are detected(e.g.,worker entering a robot cell),meeting the strictest safety standards.A German automotive plant previously used separate safety relays for robots—this siloed approach caused 3 safety incidents in 2022;after integrating 3HAC024144-001 with SR511,no incidents were reported in 2023.

Innovation Point 3:Ecosystem Compatibility for Unified Automation

The 3HAC024144-001 is engineered to work with ABB’s broader automation ecosystem:It draws stable power from the 2UBA002322R0001 PDU,receives tool wear data from P0904AK sensors,and uses UTX1700PTFE-coated cables to resist coolant corrosion in machining environments.A U.S.aerospace plant reported a 50%reduction in robot downtime by leveraging this ecosystem—previously,incompatible components required 10+hours weekly of troubleshooting.

Application Cases and Industry Value:

Case 1:Automotive Welding Robot Precision(3HAC024144-001)

A U.S.automotive plant’s IRB 6700 welding robots suffered from inconsistent weld bead placement(±0.5mm),leading to 15%of car bodies requiring rework.After installing 3HAC024144-001 controllers:

Motion precision improved to±0.05mm,aligning weld beads perfectly with chassis joints—rework costs dropped by$250,000 annually.

Integration with the 3BSE000863R1(SR511)safety controller enabled”safe speed”mode:Robots slowed to 25%speed when workers were nearby,then resumed full speed—increasing productivity by 10%(no more full shutdowns for worker access).

The 2UBA002322R0001 PDU’s redundant power prevented 2 unplanned robot outages during peak production,saving 8 hours of downtime(worth$40,000).The plant’s robotics manager stated:”The 3HAC024144-001 turned our most error-prone robots into our most reliable ones—we now meet every production target.”

Case 2:Pharmaceutical Packaging Robot Safety(3HAC024144-001)

A Swiss pharmaceutical plant needed to upgrade its IRB 1200 packaging robots to meet EU GMP and safety standards.The 3HAC024144-001 was the ideal solution:

SIL 2 compliance and integration with 3ASC25H203 safety relays ensured robots shut down if packaging trays were misaligned—preventing product contamination and meeting GMP requirements.

UTX1700PTFE-coated cables resisted isopropyl alcohol cleaning,extending cable lifespan from 1 to 3 years and reducing replacement costs by$15,000 annually.

The controller’s diagnostic features alerted maintenance teams to a failing robot motor 72 hours before failure,allowing scheduled replacement during a shift change(no production loss).The plant increased packaging capacity by 15%while maintaining 100%compliance.

Related Product Combination Solutions:

ABB 3BSE000863R1(SR511)Safety Controller:Primary safety integration partner—overrides 3HAC024144-001 motion in hazardous scenarios.

ABB 2UBA002322R0001 PDU:Provides redundant 24V DC power to 3HAC024144-001,ensuring uninterrupted robot operation.

ABB 3ASC25H203 Safety Relay:Sends emergency stop signals to 3HAC024144-001,enhancing robot cell safety.

UTX1700PTFE Industrial Cable:3HAC024144-001 paired with UTX1700PTFE-coated cables resists chemicals/coolants in manufacturing environments.

ABB PFEA112-65 Power Supply:Backs up the 2UBA002322R0001 PDU,creating a dual-layer power system for mission-critical robot cells.

FOXBORO P0904AK I/O Module:Sends analog data(e.g.,robot tool temperature,pressure)to 3HAC024144-001 for predictive maintenance.

ABB IRB 6700 Industrial Robot:Primary robot model for 3HAC024144-001—ideal for heavy-duty applications like automotive welding.

Belden 3071A Industrial Ethernet Cable:Enables high-speed PROFINET communication between 3HAC024144-001 and the SR511 safety controller.

Installation,Maintenance,and Full-Cycle Support:

Installing the 3HAC024144-001 requires DIN rail mounting in a robot control cabinet,with 15mm clearance above/below for ventilation.Connect the 24V DC power input to the ABB 2UBA002322R0001 PDU(redundant inputs recommended for critical applications)and wire digital inputs to 3ASC25H203 relays/ESD devices.For sensor integration(e.g.,P0904AK),use shielded Ethernet cables(Belden 3071A)to minimize EMI interference.In corrosive environments,use UTX1700PTFE-coated cables to protect against chemical degradation.

Routine maintenance focuses on motion precision and safety:Calibrate robot motion annually using ABB RobotStudio software—this ensures<0.1ms execution speed is maintained(drift beyond 0.2ms can cause quality issues).Inspect I/O connections quarterly for tightness,especially in high-vibration applications like stamping.Use the controller’s diagnostic logs monthly to identify early warning signs(e.g.,increasing motor current=impending wear).Replace the controller every 10 years(per ABB’s recommendation)to avoid performance degradation.

ABB provides industry-leading support for the 3HAC024144-001:All units include a 36-month warranty,with extended coverage for harsh environments(e.g.,automotive welding cells).Technical teams offer 24/7 remote troubleshooting via ABB Robotics Support Portal,and replacement parts ship globally within 48 hours.For large robotics projects,ABB provides on-site commissioning,operator training,and custom motion programming to optimize robot performance for specific applications.

Whether you need to enhance robotic precision,integrate robots with your safety system(via SR511),or ensure durability in harsh environments,the ABB 3HAC024144-001 delivers unmatched performance and integration.Contact us today to design a customized robot controller solution—backed by ABB’s 50+years of expertise in industrial robotics!

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!