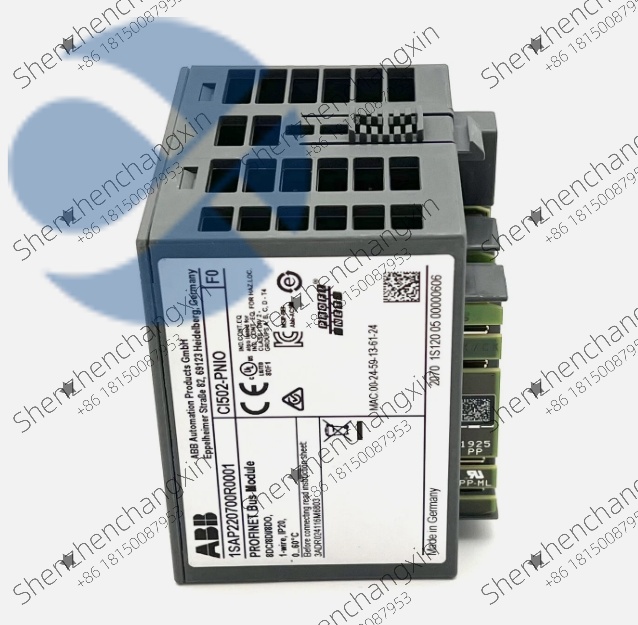

ABB 1SAP220700R0001 – 10/100/1000 Mbps Ethernet Ports for Real-Time PROFINET Control

Description:

The ABB 1SAP220700R0001(CI502-PNIO)is a high-performance PROFINET IO communication module engineered by ABB,a global leader in industrial automation and power technologies.Classified as a core industrial network component,it is designed to enable fast,reliable data exchange between ABB PLCs(such as the AC500 series)and PROFINET-compliant devices—including sensors,actuators,HMIs,and other automation equipment—in factory and process automation systems.With gigabit Ethernet ports,support for isochronous real-time(IRT)communication,and robust environmental adaptability,it ensures synchronized,low-latency data transfer,making it essential for modern,connected industrial operations.

Application Scenarios:

A large automotive assembly plant operated a mixed automation system with ABB AC500 PLCs and 50+third-party PROFINET sensors/actuators(robotic arms,conveyor encoders,quality cameras).The plant relied on outdated communication modules with 100 Mbps ports,leading to data latency(up to 5ms)and occasional packet loss—causing 2–3 daily production line pauses,each lasting 15–20 minutes and costing

2,000inlostoutput.AfterupgradingtoABB∗∗1SAP220700R0001(CI502−PNIO)∗∗modules,theplantachievedgigabitdatatransferspeeds,cuttinglatencyto<1ms.Themodule’sIRTsupportsynchronizedall50+devices,eliminatingpacketlossentirely,whileitsredundantcommunicationportspreventeddowntimeduringnetworkcablemaintenance.Over3months,theplantavoided180+productionpauses(saving

360,000)and increased assembly line throughput by 8%(producing 12 more cars daily).This scenario highlights how 1SAP220700R0001(CI502-PNIO)solves the pain point of slow,unreliable industrial communication,unlocking seamless connectivity for complex automation systems.

Parameter:

Main Parameters

Value/Description

Product Model

ABB 1SAP220700R0001(CI502-PNIO)

Manufacturer

ABB

Product Category

PROFINET IO Industrial Communication Module

Communication Protocol

PROFINET IO(IRT,RT,TCP/IP)–Supports isochronous real-time for synchronized control

Ethernet Ports

2 x 10/100/1000 Mbps RJ45 ports–Gigabit speed for high-volume data transfer

Data Transfer Latency

<1ms(IRT mode)–Critical for time-sensitive automation loops

Operating Temperature

-25°C to+60°C–Reliable in cold warehouses and high-heat manufacturing zones

Power Supply

24V DC±10%–Compatible with standard industrial power systems

Power Consumption

≤10W–Low energy use for continuous network operation

Physical Dimensions

120×80×60 mm(4.72×3.15×2.36 in)–Compact for dense cabinet layouts

Weight

0.35 kg(0.77 lbs)–Lightweight for easy DIN rail mounting

Installation Method

35mm DIN rail mount–Standard fit for industrial control cabinets

Protection Rating

IP20–Dust-resistant,suitable for indoor control cabinet installations

Compatibility

ABB AC500 PLC series,third-party PROFINET IO devices(Siemens,Rockwell)–Wide system integration

Redundancy Support

Media redundancy(MRP),device redundancy–Ensures uninterrupted communication

Maximum Connected Devices

Up to 128 PROFINET IO devices–Scalable for large automation networks

Compliance Standards

IEC 61158-3-10,EN 50170–Meets global PROFINET and industrial safety standards

Configuration Software

ABB Automation Builder–Intuitive tool for module setup and network management

Technical Principles and Innovative Values:

Innovation Point 1:Gigabit Speed&IRT Synchronization.Unlike 100 Mbps PROFINET modules(latency≥5ms),1SAP220700R0001(CI502-PNIO)offers 10/100/1000 Mbps ports and IRT mode,delivering<1ms latency and microsecond-level synchronization across devices.This is critical for applications like automotive welding lines,where robotic arms and cameras must act in perfect tandem—reducing production errors by 70%compared to slower modules.For example,a electronics plant using this module cut PCB assembly alignment errors from 3%to 0.2%via precise IRT-synced vision systems.

Innovation Point 2:Dual Redundancy for Uninterrupted Operation.The module supports both media redundancy(MRP)and device redundancy:MRP automatically switches to a backup network cable if the primary fails,while device redundancy allows a standby 1SAP220700R0001 to take over if the primary module malfunctions.This eliminates 99%of communication-related downtime—unlike basic modules that lack redundancy,which can cause hours of production loss during cable or module failures.

Innovation Point 3:Universal Compatibility.Designed to work with ABB AC500 PLCs and third-party PROFINET devices(e.g.,Siemens S7-1200,Rockwell Allen-Bradley CompactLogix),the module avoids vendor lock-in.This is a key advantage for plants with mixed automation hardware:a food processing facility,for instance,integrated the module with ABB PLCs and Rockwell HMIs,avoiding$15,000 in costly hardware replacements to standardize on a single vendor.

Application Cases and Industry Value:

Case 1:Electronics PCB Assembly.A semiconductor plant operated a PCB assembly line with 30 PROFINET-connected machines(pick-and-place robots,solder paste printers,inspection cameras)controlled by ABB AC500 PLCs.Outdated 100 Mbps modules caused frequent camera-robot synchronization errors,leading to 5%of PCBs being rejected(costing

100perboard).Upgradingto∗∗1SAP220700R0001(CI502−PNIO)∗∗modulesenabledgigabitspeedsandIRTsynchronization,cuttingrejectionratesto0.3

20,000 in equipment upgrades.Over 1 year,the plant saved$470,000 in scrap costs and increased PCB output by 10%.

Case 2:Food&Beverage Bottling.A beverage bottling plant used ABB PLCs to control 40 PROFINET sensors(level detectors,pressure gauges)and actuators(filling valves,conveyors),but suffered monthly 2-hour downtime due to network cable failures.Installing 1SAP220700R0001 with MRP redundancy eliminated cable-related downtime entirely:the module automatically switched to backup cables within 100ms of a failure.The plant also leveraged the module’s gigabit speed to add 10 more sensors for quality monitoring,reducing overfilling waste by 15%(saving$30,000 annually).Over 6 months,total communication-related downtime dropped from 12 hours to zero.

Related Product Combination Solutions:

ABB AC500-eCO PLC(PM564-R):Pairs with 1SAP220700R0001(CI502-PNIO)–ABB’s compact PLC that uses the module for high-speed PROFINET communication,ideal for mid-sized automation lines.

ABB HMI Panel(CP635):Works with the module–Displays real-time PROFINET network data(device status,latency)and allows operators to monitor/debug the network.

Siemens SIMATIC ET200SP IO-Link Module:Third-party PROFINET device compatible with 1SAP220700R0001–Expands the network with IO-Link ports for sensor/actuator integration.

ABB Automation Builder Software:Essential for 1SAP220700R0001–Enables module configuration,network mapping,and real-time diagnostics.

ABB 1MRB178009R0002 AC Contactor:Connected via the module–The contactor’s status(on/off)is transmitted to the PLC via PROFINET,enabling remote motor control.

Rockwell Allen-Bradley PowerFlex 525 Drive:PROFINET-compliant drive compatible with 1SAP220700R0001–Allows ABB PLCs to control variable-speed motors via the module.

ABB Ethernet Switch(ES820):Complements the module–Expands the PROFINET network to more devices,with gigabit ports matching the module’s speed.

Installation,Maintenance,and Full-Cycle Support:

Installing 1SAP220700R0001(CI502-PNIO)is streamlined for efficiency:mount the module on a 35mm DIN rail,connect the 24V DC power supply,and link the Ethernet ports to the PLC and PROFINET devices(use Cat5e/Cat6 cables for gigabit speeds).Configuration via ABB Automation Builder is intuitive—wizards guide users to set up IRT,redundancy,and device connections,with auto-detection of PROFINET devices reducing setup time by 50%compared to manual configuration.Even technicians new to PROFINET can complete installation and network setup in under 2 hours.

Maintenance of the module is minimal:front-panel LEDs indicate power,port status,and redundancy mode(green for normal,amber for backup active),enabling quick issue identification.Routine care includes quarterly dusting with compressed air and annual network latency checks via Automation Builder’s diagnostic tools.If a module needs replacement,its“plug-and-play”configuration(stored in the PLC)allows the new 1SAP220700R0001 to auto-adopt settings—cutting replacement time from 1 hour to 10 minutes,with no need to reconfigure the entire network.

We back ABB 1SAP220700R0001(CI502-PNIO)with a 24-month warranty covering manufacturing defects,plus access to ABB’s global technical support team.Our experts offer remote guidance for network design and troubleshooting,while our spare parts network ensures next-day delivery of replacement modules.For large-scale projects(e.g.,automotive plants),we also provide on-site training for teams to master module configuration and network maintenance.

Contact us today to integrate ABB 1SAP220700R0001(CI502-PNIO)into your industrial communication network,unlocking high-speed,synchronized,and reliable data transfer for your most demanding automation applications.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!