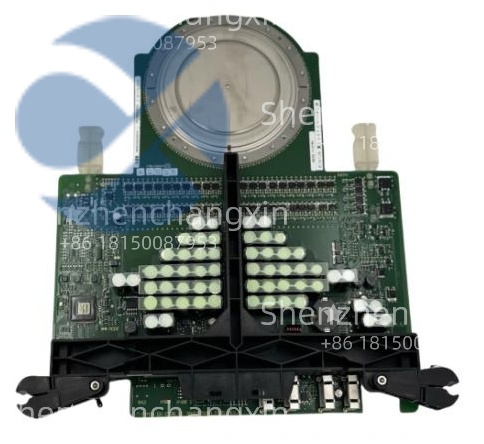

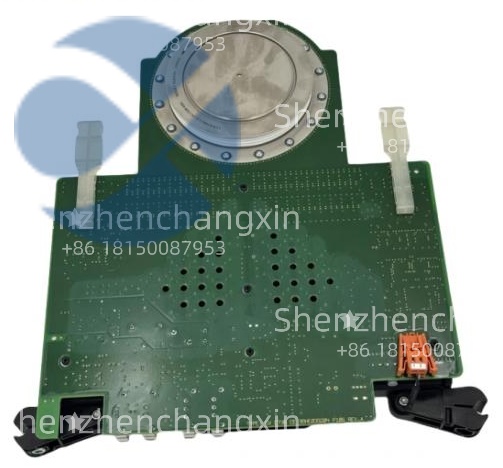

ABB 3BHB030310R0001 Power Module | ACS800/ACS880 Drive Replacement Part

Description

TheABB 5SHY4045L0006 3BHB030310R0001 is a high-power IGBT (Insulated-Gate Bipolar Transistor) semiconductor module manufactured by ABB for its medium-voltage AC drives and power conversion systems. It functions as the core switching component within the inverter or converter power stack, responsible for precisely controlling the flow of electrical power to an electric motor or grid. This robust module is engineered to handle high voltages and currents, enabling efficient, variable-speed control of large industrial motors with high reliability.

Application Scenarios

Consider the main induced draft fan drive in a large coal-fired power plant, a 6,000 kW motor critical for maintaining proper furnace pressure. The variable frequency drive controlling this motor, an ABB ACS 1000, suffers a catastrophic failure in one phase of its inverter section during peak operation. The plant faces a potential boiler shutdown, risking millions in lost generation. The faulty component is identified as theABB 5SHY4045L0006 3BHB030310R0001 IGBT module. This module is the workhorse that switches the high DC bus voltage into a precisely controlled AC waveform for the motor. Replacing it with a genuine, factory-matched module is the only path to a reliable, long-term repair. In this high-stakes scenario, the5SHY4045L0006 is not just a spare part; it is the key to restoring the drive’s ability to smoothly regulate fan speed, ensuring stable combustion, optimal efficiency, and preventing a forced outage that could last for days. Its performance directly impacts the plant’s availability, efficiency, and bottom line.

Parameter

Main Parameters

Value/Description

Product Model

5SHY4045L0006 (also referenced as3BHB030310R0001)

Manufacturer

ABB

Product Category

High-Power IGBT (Insulated-Gate Bipolar Transistor) Module

Voltage Rating

Typically 3300V or 4500V (collector-emitter voltage, VCES).Defines the maximum voltage the switch can block.

Current Rating

High Current (e.g., 1200A, 1600A) (collector current, IC).Defines the continuous current carrying capacity.

Circuit Configuration

Dual IGBT (2-in-1 module) or other configuration.Contains multiple IGBTs and diodes in one package for a phase leg.

Package Type

High-power, press-pack or module-style with large bus bar connections.

Switching Frequency

Designed for typical drive frequencies (a few hundred Hz to ~1kHz).Optimized for a balance of efficiency and switching losses.

Application

Inverter/Converter Power Stack in Medium Voltage AC Drives (e.g., ABB ACS 800, ACS 1000, ACS 6000).

Mounting

Requires assembly into a liquid- or air-cooled heatsink with precise pressure and thermal interface.

Key Feature

Integrated diode for freewheeling current, essential for motor drive applications.

Technical Principles and Innovative Values

TheABB 5SHY4045L0006 3BHB030310R0001 is built on the principle of efficient, robust, and controllable power switching, representing a pinnacle of power semiconductor technology for industrial applications.

Innovation Point 1: Advanced IGBT Silicon Technology. At its heart, the module utilizes ABB’s proprietary IGBT chip technology, engineered for a favorable trade-off between conduction loss and switching loss. This allows the drive to operate at higher efficiencies, reducing energy waste as heat. The precise doping and structure of the silicon wafer enable fast switching while maintaining ruggedness against short-circuit events, a critical requirement for protecting motors and the drive itself during faults.

Innovation Point 2: Optimized Module Packaging for High Reliability. The5SHY4045L0006 is not just a collection of silicon dies. Its innovation lies in its advanced packaging. It uses materials with matched coefficients of thermal expansion to minimize mechanical stress during power cycling (heating/cooling). The internal bonding, using heavy aluminum wires or strips, is designed to handle high current and thermal fatigue. This robust construction is what allows it to survive the harsh thermal cycling of industrial duty for decades, a key differentiator from lesser-quality modules.

Innovation Point 3: Integration for Simplified Power Stack Design. The module integrates multiple necessary components—typically two IGBTs and their associated anti-parallel diodes—into a single, mechanically standardized package. This “2-in-1” or similar configuration significantly simplifies the design and assembly of the three-phase inverter bridge. For drive manufacturers and service personnel, this integration reduces the number of discrete connections, improves reliability, and makes the power stack more compact and serviceable.

Innovation Point 4: Enabling Advanced Motor Control and Protection. The performance characteristics of the5SHY4045L0006—its switching speed, saturation voltage, and short-circuit withstand time—are fundamental to the capabilities of the entire drive. They allow the drive’s control board to implement sophisticated PWM (Pulse Width Modulation) patterns for smooth motor torque, high dynamic response, and advanced features like ride-through. Furthermore, its predictable failure modes under stress are integral to the drive’s layered protection schemes.

Application Cases and Industry Value

Case Study: Reliability Upgrade in a Mining Grinding Mill Drive

A copper mine in South America operated several large grinding mills powered by 8 MW synchronous motors using ABB ACS 1000 drives. The original IGBT modules, after 12 years of 24/7 operation, began showing signs of thermal fatigue, leading to unscheduled downtime. The mine embarked on a proactive replacement program, sourcing newABB 5SHY4045L0006 3BHB030310R0001 modules. The new modules, featuring improved silicon technology, resulted in a measurable 0.5% reduction in inverter losses compared to the old modules. This translated directly to lower cooling requirements and energy savings. More importantly, the predictable maintenance window and use of genuine parts restored the drives to like-new reliability. The maintenance superintendent noted, “The controlled swap with the5SHY4045L0006 modules gave us confidence. We eliminated the random failures that were costing us hundreds of tons of production per event. The drive’s performance and diagnostic readings are now textbook perfect.”

Case Study: Modernization of a Petrochemical Plant Compressor Drive

A Middle Eastern petrochemical plant needed to modernize the control system of a critical cracked gas compressor while retaining the existing motor and robust ABB ACS 6000 power stack. The project involved replacing the legacy control interface but required absolute certainty in the integrity of the power stage. TheABB 5SHY4045L0006 modules were meticulously tested in-situ. Their data plates were cross-referenced, and their thermal interface and mounting pressure were verified and logged as a baseline. This process confirmed the power stack as fully operational, de-risking the control system upgrade. The plant engineers stated that the known, documented reliability of these core power components was a foundational element in securing project approval, as it isolated the upgrade risk to the new control electronics only.

Related Product Combination Solutions

TheABB 5SHY4045L0006 3BHB030310R0001 is a central component within a larger power electronics ecosystem. Key related parts include:

Gate Drive Unit (e.g., ABB 5SHY…GDU or 3BHE…): This is the critical interface between the low-voltage control signals and the high-power IGBT. It provides the necessary voltage to switch the5SHY4045L0006 on/off, provides isolation, and monitors for faults like short-circuits.

DC Link Capacitor Bank: Provides the stable, smoothed high-voltage DC bus that the5SHY4045L0006 modules switch from. Its health is crucial for module longevity.

Snubber Circuits/Clamping Modules: Often used in parallel with IGBTs to suppress voltage spikes during switching, protecting the sensitive5SHY4045L0006 from over-voltage stress.

Liquid-Cooled Heatsink (e.g., with specific manifold part number): The module is mounted under precise pressure onto this heatsink, which carries away the significant heat generated during operation. Proper thermal interface material (TIM) and mounting torque are critical.

Current Sensors (e.g., LEM or ABB make): Measure the output current of each phase, providing essential feedback for the drive’s control and protection algorithms that govern the5SHY4045L0006.

Control Board (e.g., ABB NTAC-01, NIMP-01): Generates the PWM firing pulses sent to the Gate Drive Units, which in turn control the5SHY4045L0006 modules.

Fuses (High Speed Semiconductor Fuses): Act as the ultimate protective device in series with each IGBT module or phase leg, designed to clear a catastrophic fault before it destroys the entire stack.

Installation, Maintenance, and Full-Cycle Support

Installation and Commissioning: Installing anABB 5SHY4045L0006 3BHB030310R0001 module is a high-precision task requiring strict adherence to procedure. It begins with verifying the replacement module matches the original in all electrical and mechanical specifications. The drive must be completely isolated, locked out, and tested for zero energy. The old module is carefully removed, and the heatsink surface is meticulously cleaned. A new, uniform layer of thermal grease (or a phase-change pad) is applied. The new module is then positioned and bolted down with a calibrated torque wrench to the exact specification—uneven pressure is a primary cause of premature failure. Electrical connections are made, ensuring bus bars are clean and tight. After reassembly, the drive undergoes a detailed commissioning sequence, including low-voltage functional tests and careful ramp-up under load, to validate the installation.

Maintenance and Troubleshooting: Preventive maintenance is key. This involves regular thermographic inspections of the power stack to detect hot spots, checking cooling system performance (flow, temperature), and monitoring for any audible or electrical signs of arcing. A failing5SHY4045L0006 module may manifest as increased earth leakage current, unbalanced output currents, or overtemperature alarms. Troubleshooting requires specialized equipment to safely test high-voltage components. Often, the diagnosis involves insulation resistance testing and, if possible, a static IGBT test with a specialized tester to check the semiconductor junctions.

Support and Service Commitment: We provide comprehensive support for these critical components. Our service begins with authentic part verification, ensuring the5SHY4045L0006 module is genuine ABB or a certified equivalent with full traceability. We offer technical documentation, including detailed mounting instructions and torque specifications. Beyond the sale, we can provide access to field service engineers specializing in medium-voltage drive repair for installation supervision or complex diagnostics. Our commitment is to be your partner in maintaining drive uptime, offering not just a component, but the expertise and support for a successful, reliable repair that extends the operational life of your capital equipment.

Secure the core of your drive’s power stage with genuine, reliable components. Contact us today for the ABB 5SHY4045L0006 3BHB030310R0001 IGBT module and expert support for your medium-voltage drive system.