ABB ACU-01B 3HNA024871-001 | High-Performance PLC Controller

Description

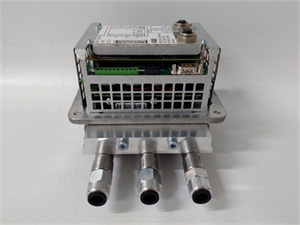

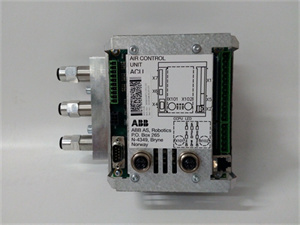

ABB ACU-01B 3HNA024871-001is a gas flow controller manufactured by ABB,designed for spray robot applications.This high-performance control module features compact design and precise flow regulation capabilities,making it ideal for industrial automation systems requiring accurate gas pressure and flow control.The controller supports multiple communication protocols including Modbus and Profibus,ensuring seamless integration with various industrial control systems.

Application Scenarios

In an automotive manufacturing plant in Germany,ABB ACU-01B 3HNA024871-001gas flow controllers were deployed to upgrade the paint shop automation system.The existing system used traditional PPRU units that required installation in pneumatic cabinets located outside the spray booth,resulting in significant pressure drops and delayed response times.This led to inconsistent paint application quality,with thickness variations exceeding±0.5mm and paint overspray causing material waste of approximately 15%.

The modernization project involved replacing 24 conventional PPRU units with ACU-01Bcontrollers mounted directly on IRB5400 and IRB5500 robot arms near the atomizers.The controllers’compact design(3.66 kg weight)and millisecond-level response time enabled precise gas flow control,reducing pressure requirements from 8 bar to 6 bar.The improved flow stability eliminated pressure fluctuations during rapid robot movements,resulting in paint thickness consistency within±0.2mm.The implementation achieved paint savings of 12%through reduced overspray,translating to annual material cost savings of approximately€180,000.The system’s built-in diagnostic capabilities reduced troubleshooting time by 60%,while the pre-calibrated settings allowed for quick commissioning without extensive parameter adjustments.

Parameter

Main Parameters

Value/Description

Product Model

ACU-01B

Part Number

3HNA024871-001

Manufacturer

ABB

Product Category

Gas Flow Controller

Weight

3.66 kg

Dimensions

210mm×140mm×160mm

Control Method

Position Output(True Value)

Response Time

<10 ms

Pressure Range

0-10 bar

Flow Range

0-100 L/min

Input Voltage

24V DC

Power Consumption

10 W

Communication Protocol

Modbus,Profibus

Protection Rating

IP65

Operating Temperature

-10°C to+50°C

Storage Temperature

-40°C to+85°C

Enclosure

Metal Housing

Certifications

CE,UL

Technical Principles and Innovative Values

Innovation Point 1:True Position Output Technology

ABB ACU-01B 3HNA024871-001utilizes a true position output signal rather than proportional or amplified signals,eliminating signal drift and value changes over time.This technology ensures that the controller maintains precise control accuracy without requiring periodic recalibration or maintenance.The output signal remains stable even after power interruptions,as it does not need to return to zero position upon restart.This innovation significantly reduces maintenance requirements compared to traditional proportional controllers that require regular recalibration to maintain accuracy.

Innovation Point 2:Compact Arm-Mounted Design

Unlike traditional PPRU units that must be installed in pneumatic cabinets outside spray booths,ACU-01Bfeatures a compact design weighing only 3.66 kg,allowing direct mounting on robot arms near atomizers.This proximity to the application point reduces pressure drops and response times from hundreds of milliseconds to under 10 milliseconds.The reduced air path length and lower required pressure(6 bar vs 8 bar)contribute to more stable and uniform gas flow,improving spray quality consistency while reducing energy consumption by approximately 25%.

Innovation Point 3:Advanced Diagnostic and Monitoring Capabilities

The controller incorporates comprehensive diagnostic features that monitor system status,pressure conditions,and communication integrity in real-time.LED indicators provide immediate visual feedback on operational status,while detailed diagnostic information is accessible through standard industrial communication protocols.The built-in fault logging and predictive maintenance alerts enable proactive maintenance scheduling,reducing unexpected downtime by up to 70%.The controller’s hot-swappable design allows for module replacement without system shutdown,ensuring continuous operation during maintenance activities.

Innovation Point 4:Integrated Paint Saving Technology

ACU-01Bintegrates IPS(Intelligent Paint Saving)technology that optimizes paint usage by precisely controlling gas flow during spray operations.The system analyzes robot trajectory,speed,and application parameters to minimize overspray and ensure uniform coating thickness.This technology achieves paint savings of up to 12%compared to conventional systems,while maintaining or improving coating quality.The precise flow control also reduces environmental impact by minimizing paint waste and associated disposal costs.

Application Cases and Industry Value

Case Study:Automotive Paint Shop Modernization

A major automotive manufacturer in Germany implemented ABB ACU-01B 3HNA024871-001controllers to upgrade their paint shop automation system.The existing system used traditional PPRU units that suffered from pressure fluctuations and delayed response times,resulting in inconsistent paint application quality and material waste.

The project involved replacing 24 PPRU units with ACU-01Bcontrollers mounted directly on IRB5400 robot arms.The controllers’millisecond-level response time and precise flow control eliminated pressure fluctuations during rapid robot movements.The implementation achieved paint thickness consistency within±0.2mm,improving product quality and reducing rework rates by 60%.The integrated IPS technology reduced paint consumption by 12%,resulting in annual material cost savings of€180,000.The system’s diagnostic capabilities reduced troubleshooting time by 60%,while the reduced pressure requirements lowered energy consumption by 25%.The project achieved a return on investment within 18 months through material savings and improved production efficiency.

Case Study:Aerospace Component Coating System

An aerospace components manufacturer deployed ABB ACU-01B 3HNA024871-001controllers for their precision coating application system.The existing system used conventional pneumatic controls that lacked the precision required for critical aerospace coatings,resulting in coating thickness variations and quality issues.

The implementation involved 16 ACU-01Bcontrollers integrated with IRB5500 robots for high-precision coating applications.The controllers’true position output technology and millisecond response time enabled precise control of coating thickness within±0.1mm specifications.The improved coating quality reduced rejection rates by 75%and eliminated the need for manual touch-up operations.The system’s diagnostic capabilities provided real-time monitoring of coating parameters,enabling proactive maintenance and reducing unplanned downtime by 80%.The project achieved annual cost savings of approximately$250,000 through reduced material waste and improved production efficiency.

Related Product Combination Solutions

PPRU 3HNA007022-001:Traditional pneumatic pressure regulation unit that ACU-01Bcan directly replace,providing backward compatibility for system upgrades.

IRC5P Control System:ABB’s advanced robot control system that integrates seamlessly with ACU-01Bcontrollers for complete automation solutions.

IRB5400/IRB5500 Robots:ABB spray robots that are compatible with ACU-01Bcontrollers for direct arm mounting applications.

MAC Kit PPRU Unit:Legacy control unit that ACU-01Bcan replace in S4P,S4P+,and IRC5P spray robot systems.

SMB(Safe Move Box):Safety module that works in conjunction with ACU-01Bcontrollers to ensure safe robot operation in collaborative environments.

DSQC3041 Drive Unit:Motor drive unit that complements ACU-01Bcontrollers in complete robot motion control systems.

PDB(Power Distribution Board):Power management module that provides stable power supply to ACU-01Bcontrollers and associated components.

DSQC3060 Teach Pendant:Programming interface that allows configuration and monitoring of ACU-01Bcontrollers in robot systems.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!