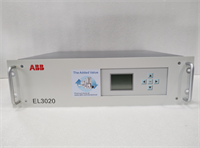

ABB EL3020 | EtherCAT I/O Terminal with 16-Bit Resolution for Precision Contro

Description

The ABB EL3020 is a compact,high-speed analog input terminal from ABB’s EtherCAT I/O portfolio,designed for distributed control architectures requiring deterministic,real-time signal acquisition.As part of the modular EL series compatible with ABB’s AC500 PLCs and IRC5 robot controllers,the EL3020 delivers precise voltage measurement with 16-bit resolution and microsecond-level update cycles—ideal for motion feedback,process monitoring,and machine diagnostics.

Application Scenarios

In a high-speed bottling line in Central Europe,an OEM integrator faced inconsistent fill-level control due to delayed analog feedback from pressure sensors.Traditional fieldbus I/O introduced latency that disrupted the servo-driven filling valves.By deploying the ABB EL3020 directly on the machine frame—connected via EtherCAT to an ABB AC500-S CPU—the system achieved sub-100µs I/O update times.The EL3020’s two±10 V channels captured real-time pressure deviations,enabling immediate PID correction.Cycle-to-cycle variance dropped by 65%,and product giveaway was reduced by over 200,000 liters annually.In this application,the EL3020 proved not just as a signal interface,but as a performance multiplier in a precision motion-control ecosystem.

Parameter

Main Parameters Value/Description

Product Model EL3020

Manufacturer ABB

Product Category 2-Channel Analog Input Terminal(EtherCAT)

Input Channels 2 single-ended voltage inputs

Signal Range±10 V,0–10 V(software-selectable per channel)

Resolution 16 bits(65,536 counts)

Accuracy±0.1%of full scale

Sampling Rate Up to 10 kHz per channel

Cycle Time(EtherCAT)As low as 100µs(depends on network configuration)

Electrical Isolation 500 Vrms between field side and EtherCAT bus

Communication Protocol EtherCAT(CoE–CAN application protocol over EtherCAT)

Installation Method DIN rail mount;hot-pluggable;daisy-chainable with other EL terminals

Operating Temperature 0°C to+55°C

Technical Principles and Innovative Values

Innovation Point 1:True Real-Time Performance via EtherCAT

The EL3020 leverages EtherCAT’s“processing-on-the-fly”architecture,eliminating switch-induced delays.Data from its 16-bit ADC is inserted directly into the passing Ethernet frame—enabling deterministic updates unmatched by traditional fieldbuses like Profibus or Modbus RTU.

Innovation Point 2:Per-Channel Software Configurability

Unlike fixed-range modules,each channel on the EL3020 can be independently set to±10 V or 0–10 V via ABB’s Automation Builder or TwinCAT,allowing mixed-signal applications(e.g.,position feedback+torque reference)in a single terminal.

Innovation Point 3:Seamless ABB Ecosystem Integration

The EL3020 is natively supported in ABB’s AC500 PLC programming environment and can be directly addressed by IRC5 robot controllers for closed-loop motion tasks—eliminating gateways or protocol converters.

Innovation Point 4:Compact,Modular,and Scalable

At just 12 mm wide,the EL3020 fits into space-constrained cabinets.Multiple EL terminals(digital,analog,specialty)can be daisy-chained without switches or hubs,reducing cabling cost by up to 70%.

Application Cases and Industry Value

At an automotive battery module assembly line in Germany,the ABB EL3020 was deployed to monitor clamping force during cell stacking.Two strain-gauge amplifiers output±10 V signals representing upper and lower press forces.Connected via EtherCAT to an AC500-S safety PLC,the EL3020 provided synchronized,high-fidelity data used in a real-time quality check algorithm.Any deviation beyond±2%triggered automatic rejection—preventing defective modules from reaching welding stations.Over 18 months,the system achieved zero field failures linked to stacking pressure,saving an estimated€1.2M in warranty claims.Operators praised the EL3020’s plug-and-play setup and diagnostic LEDs,which cut troubleshooting time by half during line changeovers.